17

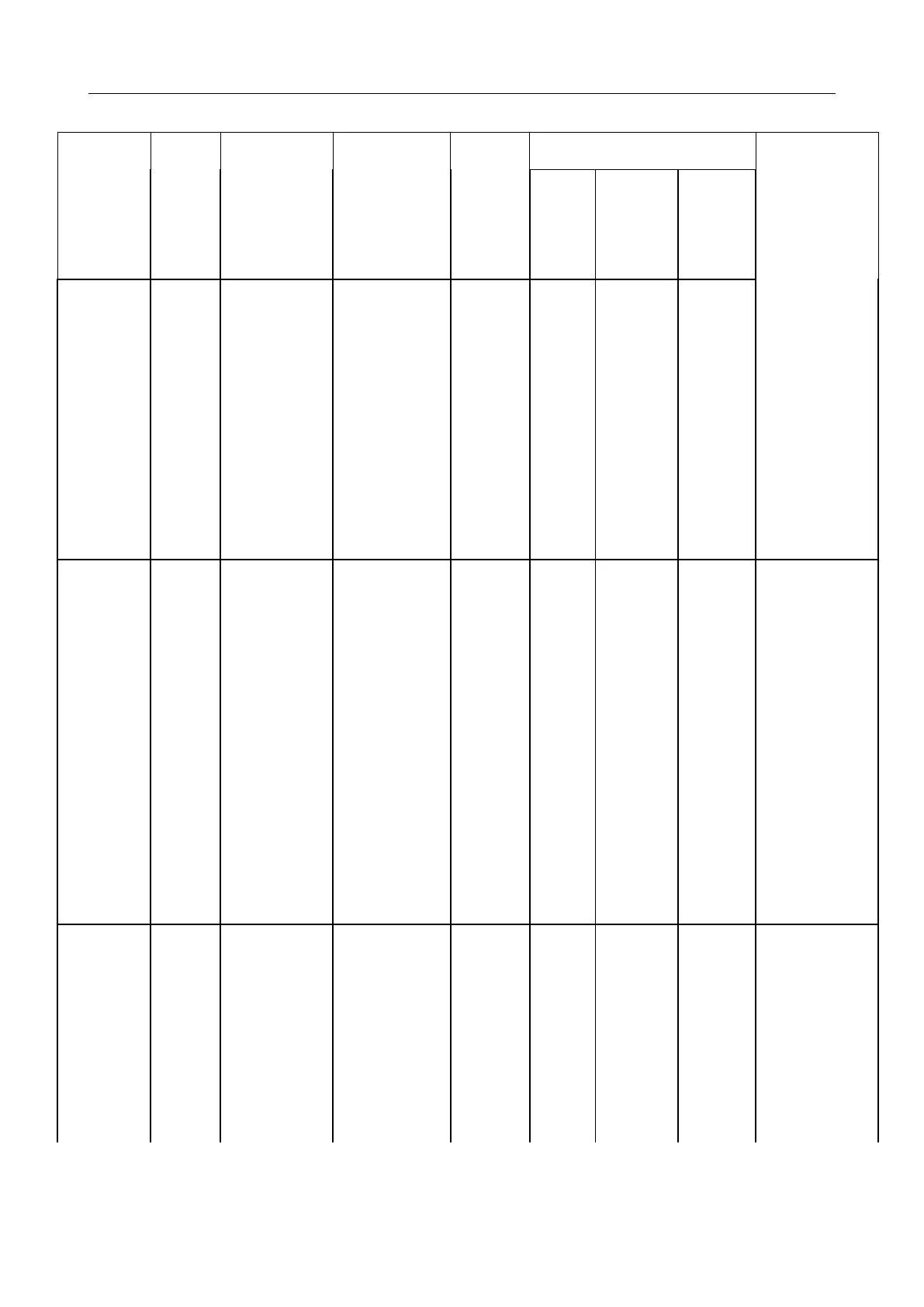

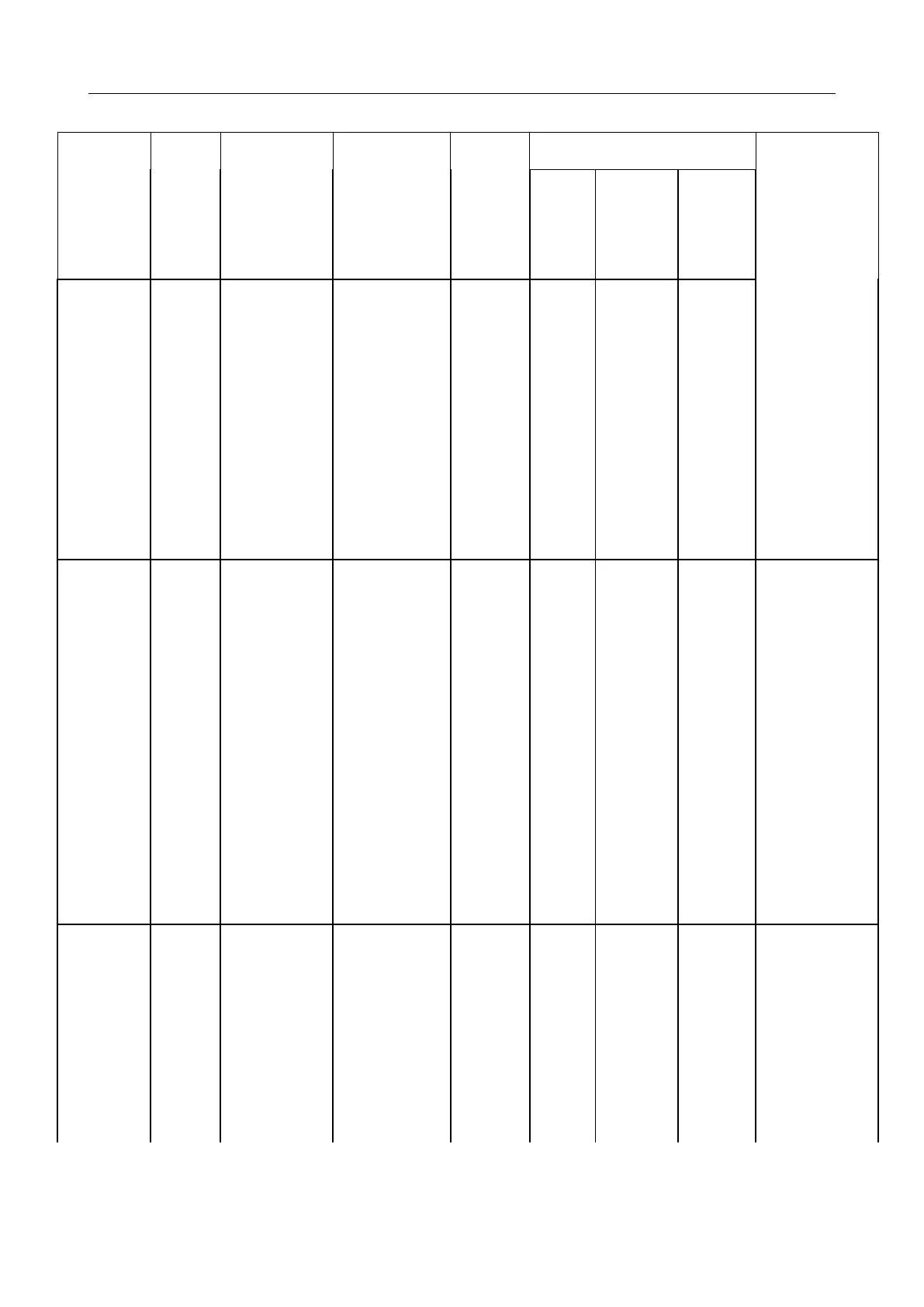

Parameters for TIG welding on titanium and its alloy (for reference only)

Plate

thickness

mm (inch)

Weldin

g

layers

Electrode

diameter mm

(inch)

Wire

diameter mm

(inch)

Welding

current(

A)

Gas flow (L/min)

Nozzle

diameter

mm (inch)

Square

groove

Single V

groove

with root

face

Double V

groove

with root

face

0.5(0.020") 1 1.5(0.059") 1 (0.040") 30~50 8~10 6~8 14~16 10(0.393")

1 (0.040") 1 2(0.079")

1.0~2.0

(0.040"-0.079")

40~60 8~10 6~8 14~16 10(0.393")

1.5(0.060") 1 2(0.079")

1.0~2.0

(0.040"-0.079")

60~80 10~12 8`10 14~16

10~12

(0.393"-0.472)

2(0.079") 1

2.0~3.0

(0.079"-0.118")

1.0~2.0

(0.040"-0.079")

80~110 12~14 10~12 16~20

12~14

(0.472"-0.551")

2.5(0.098") 1

2.0~3.0

(0.079"-0.118")

2 (0.079") 110~120 12~14 10~12 16~20

12~14

(0.472"-0.551")

3(0.118") 1~2 3(0.12")

2.0~3.0

(0.079"-0.118")

120~140 12~14 10~12 16~20

14~18

(0.551"-0.708")

4(0.157") 2

3.0~4.0

(0.12~5/32")

2.0~3.0

(0.079"-0.118")

130~150 14~16 12~14 20~25

18~20

(0.708"-0.787")

5(0.197") 2~3 4.0(5/32”) 3(0.118") 130~150 14~16 12~14 20~25

18~20

(0.708"-0.787")

6(0.236") 2~3 4.0(5/32”)

3.0~4.0

(0.118"-5/32”)

140~180 14~16 12~14 25~28

18~20

(0.708"-0.787")

7(0.257") 2~3 4.0(5/32”)

3.0~4.0

(0.118"-5/32”)

140~180 14~16 12~14 25~28

20~22

(0.787"-0.866")

8(0.315") 3~4 4.0(5/32”)

3.0~4.0

(0.118"-5/32”)

140~180 14~16 12~14 25~28

20~22

(0.787"-0.866")

10(0.394") 4~6 4.0(5/32”)

3.0~4.0

(0.118"-5/32”)

160~200 14~16 12~14 25~28

20~22

(0.787"-0.866")

20(0.787") 12 4.0(5/32”) 4(5/32”) 200~240 12~14 10~12 20 18(0.708")

22(0.866") 12 4.0(5/32”)

4.0~5.0

(5/32”-0.197")

230~250 15~18 18~20 18~20 20(0.787")

25(0.984") 15~16 4.0(5/32”)

3.0~4.0

(0.118"-5/32”)

200~220 16~18 20~26 26~30 22(0.866")

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...