Notice: The melting current of the fuse is 1.2~1.5 times its rated current.

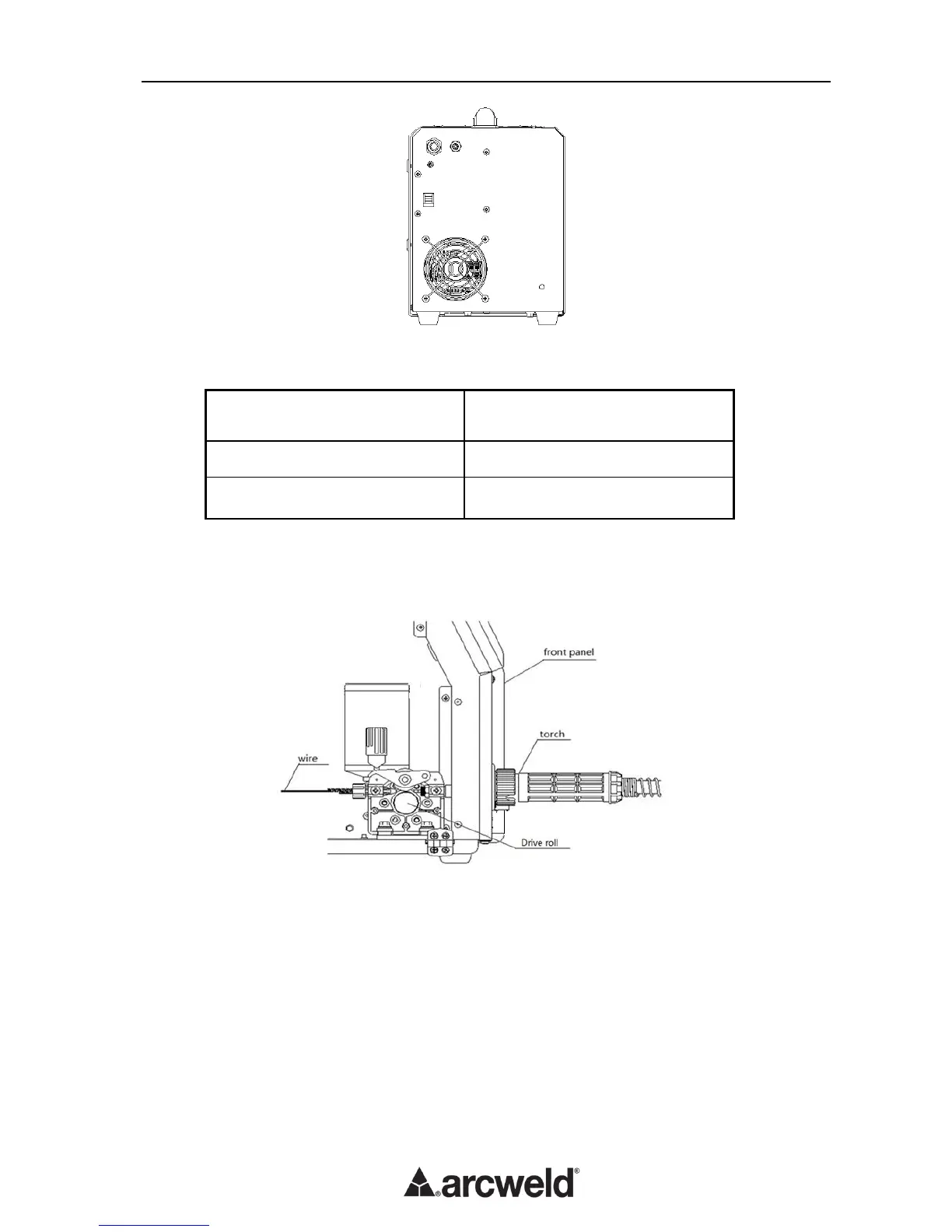

The installation and connection for MIG welding

* Select a suitable filler wire according to process being used (Lincoln Ultramag S6 for MIG and

Innershield NR211MP for gasless flux cored welding). The wire diameter must be matched to the

drive roll, the liner and contact tip.。

* Open the side panel of wire feeder and mount the wire spool on the spool post. The end of the wire

must be at the bottom of the wire spool, opposite wire feeder inlet guide tube.

* The spool post is fitted with a brake; the wing nut in the centre of the spool post adjusts the brake

tension. Pull the wire from the reel by hand and adjust the tension to provide some drag - clockwise

will increase the braking and anticlockwise reduces it.

Loading...

Loading...