F-1 MAINTANCE AND TROUBLESHOOTING F-1

MAINTENANCE

In order to guarantee the arc welding machine works efficiently and safely, it must be maintained regularly.

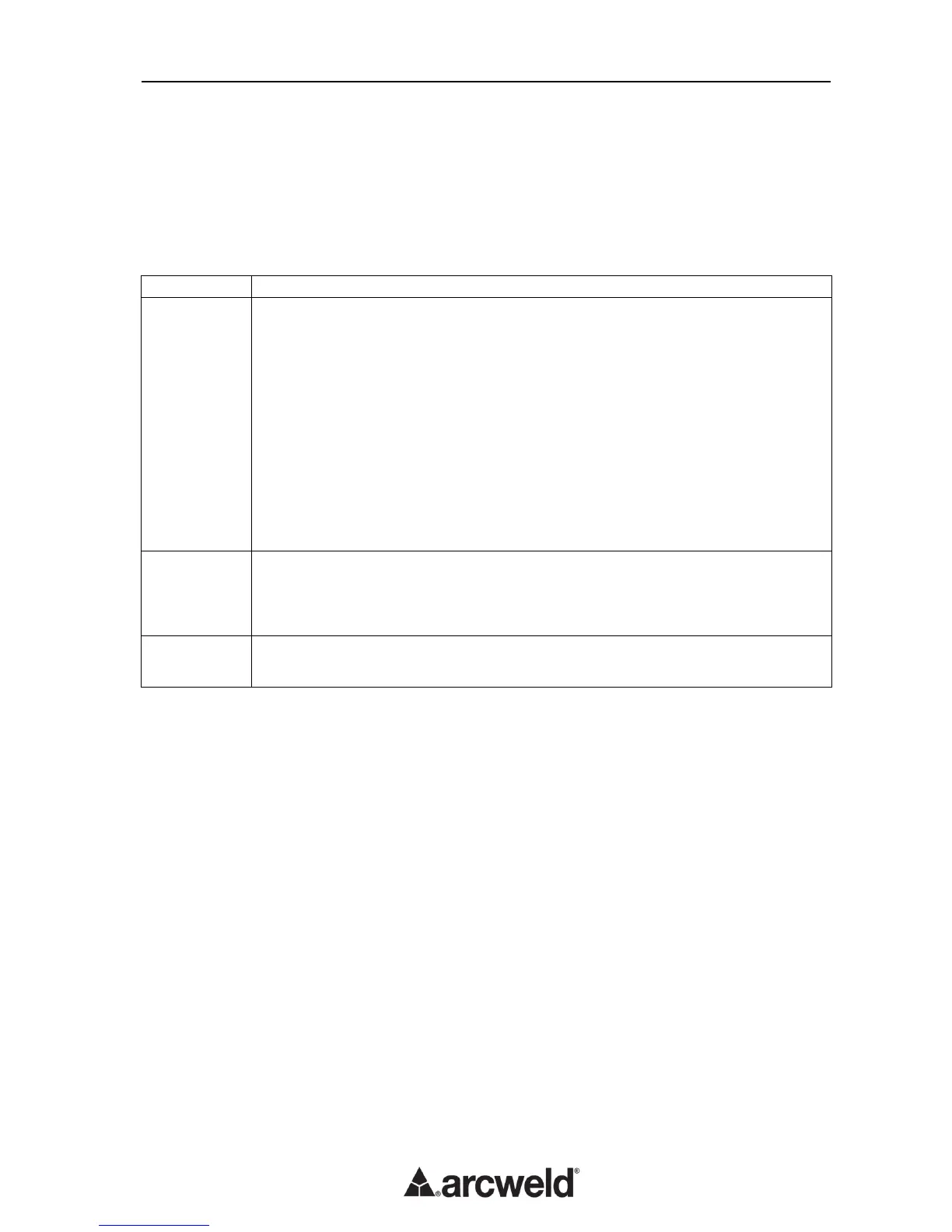

Refer to the maintenance items in the following table.

● Warning: For safety while maintaining the machine, please disconnect the supply power and

wait for 5 minutes, until capacitor voltage drops to safe voltage.

All service work should be conducted by an authorised Lincoln Electric field service agent

Check operation of the panel knob’s and switch’s on the front and at the back of arc

welding machine are operational and operate correctly.

If the switch is not operational, replace immediately.

Check the function of the LED display. If it doesn’t work, maintain or replace the display

PCB.

Check fan is operating normally. If the fan is damaged, change immediately. If the fan

does not rotate after the arc welding machine is overheated, check if something blocking

the fan blade, if it is blocked, remove the obstruction. If the fan still does not rotate try

to spin the blade in the rotation direction of fan. If the fan rotates normally, the start

capacitor should be replaced; If not, change the fan.

Check the output terminals for overheating, if so change output terminals. Ensure

welding lead plugs are connected tightly.

Check welding leads for damage. If damaged replace leads.

Using dry compressed air to clear the inside of arc welding machine. Especially remove

dust from heat sinks, main voltage transformer, inductance, IGBT module, the fast

recover diode and PCB, etc.

Loading...

Loading...