CH9 故障排除 Trouble-Shooting Original

57

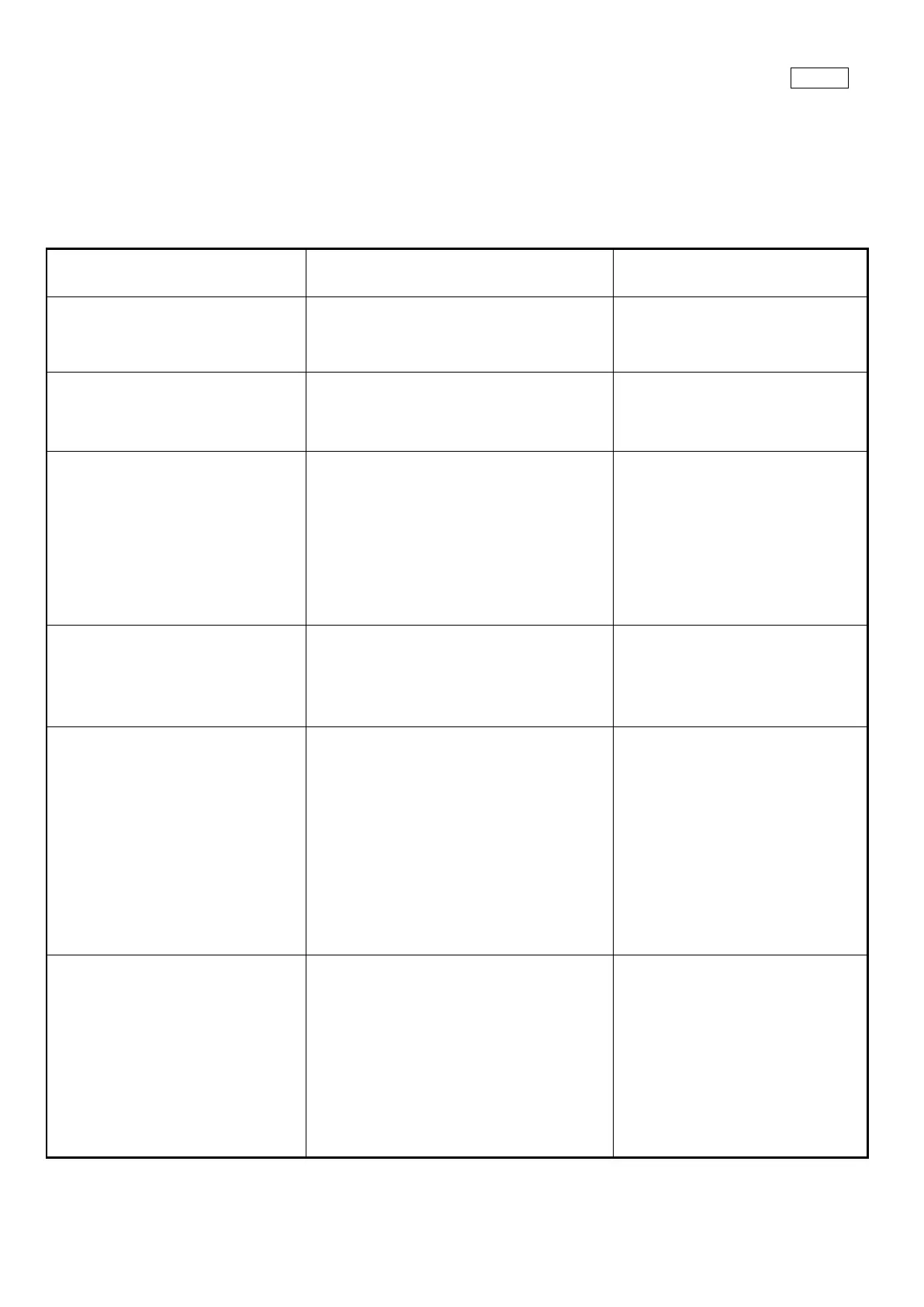

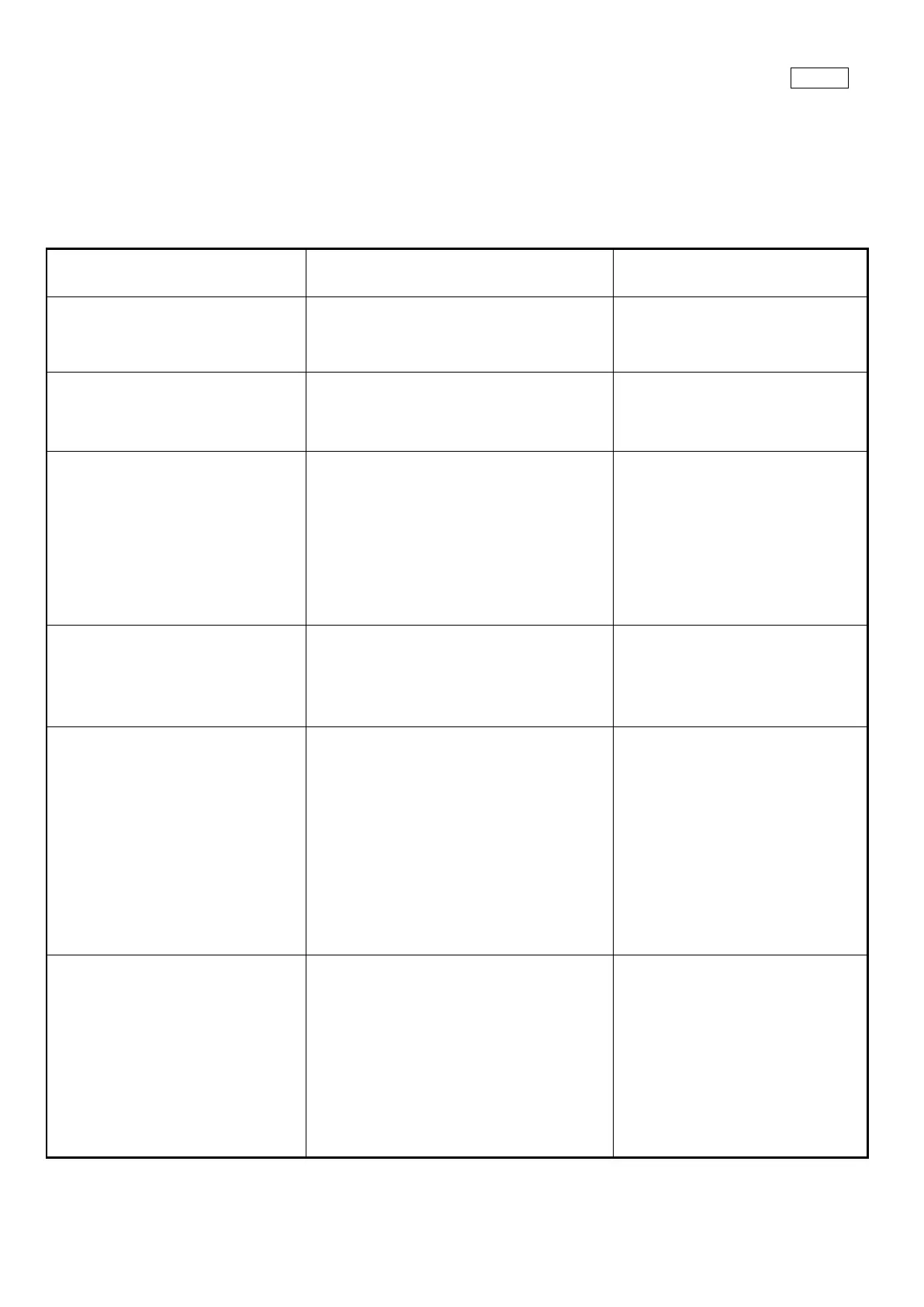

下表所列的是關於在操作時可能發生的故障,及其可能的原因與處理方法

The following chart contains some typical probable troubles of operation, along with the

possible causes and remedies for each.

主軸進給不順

Spindle feed un-normal

昇降套固定桿未放鬆

Quill clamp lever unrelease

放鬆固定桿

Release clamp lever

主軸剎車失靈

Spindle brake brake-down

剎車環磨損

Brake shoe worn out

(1) 開關接觸不良

Poor contact on the switch

(2) 皮帶太鬆

Drive belt too slack

(3) 馬達出毛病

Poor motor

(1) 檢查電源開關

Check the switch

(2) 調整或更換

Adjust or replace

(3) 修理或更新

Repair or renew

電源開關扭轉位置不對

The switch knob indicated at

wrong position

轉變開關指示位置

Change to correct position

工作台上下、前後、左右

進給不順

Table vertical, cross,

longitudinal feed unsmooth

(1) 調整楔太緊

Gib strip too tight

(2) 螺帽與螺桿間隙不當

Unproper backlush between

unt and screws

(3) 潤滑油未至達潤滑面

The lubricant not to

lubrication point.

放鬆調整楔

Release

調整間隙

Adjust

檢查潤滑油路

Check lubrication

切削時震動

Vibrative when machining

(1) 機械不穩固

Machine unstable

(2) 切削條件不適當

Unsuitable cutting condition

重新固定機械

Reclamp

依材質和銑刀大小選適

當切削速度

Select proper cutting speed

according to materials and

cutter

Loading...

Loading...