CH9 故障排除 Trouble-Shooting Original

61

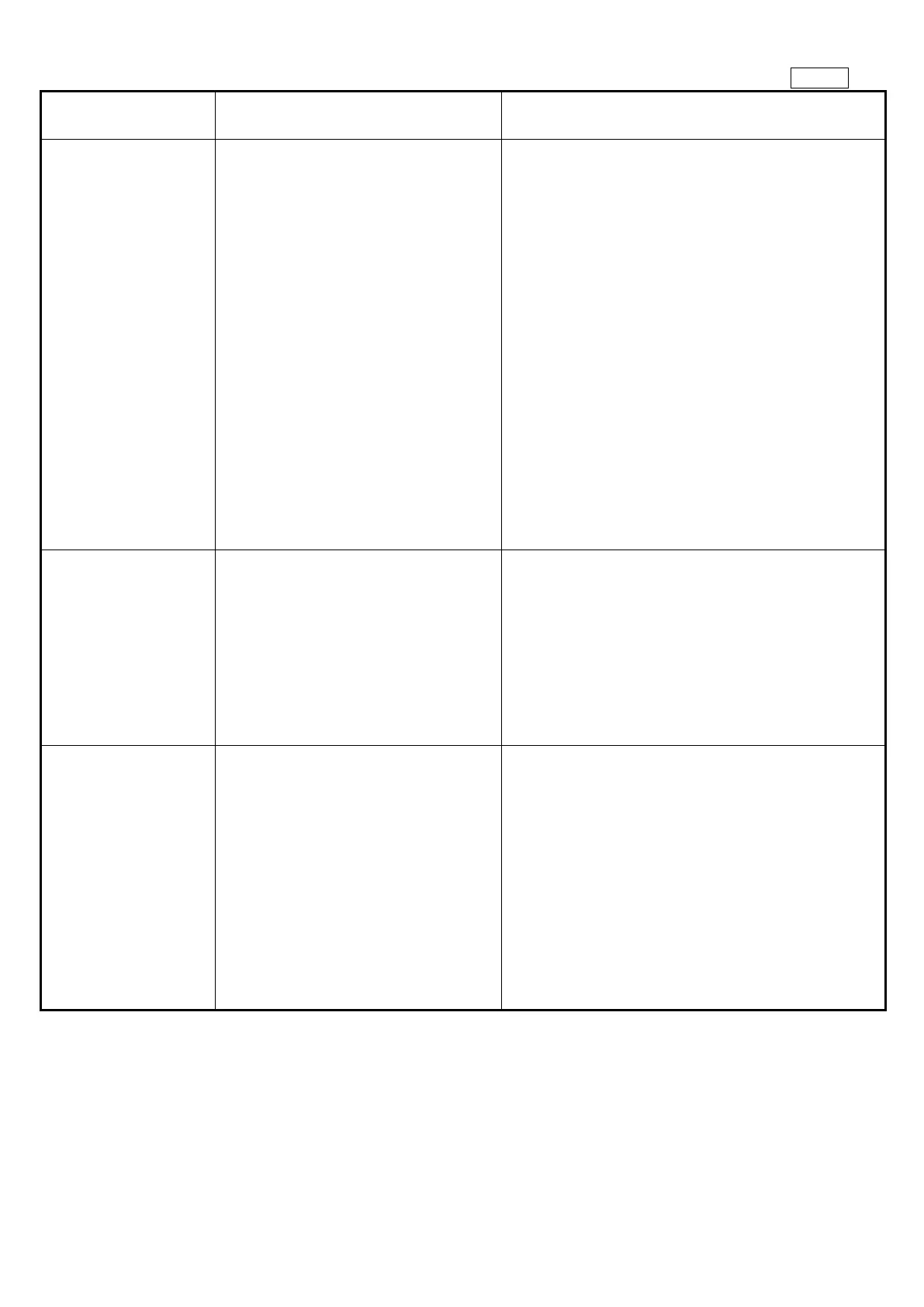

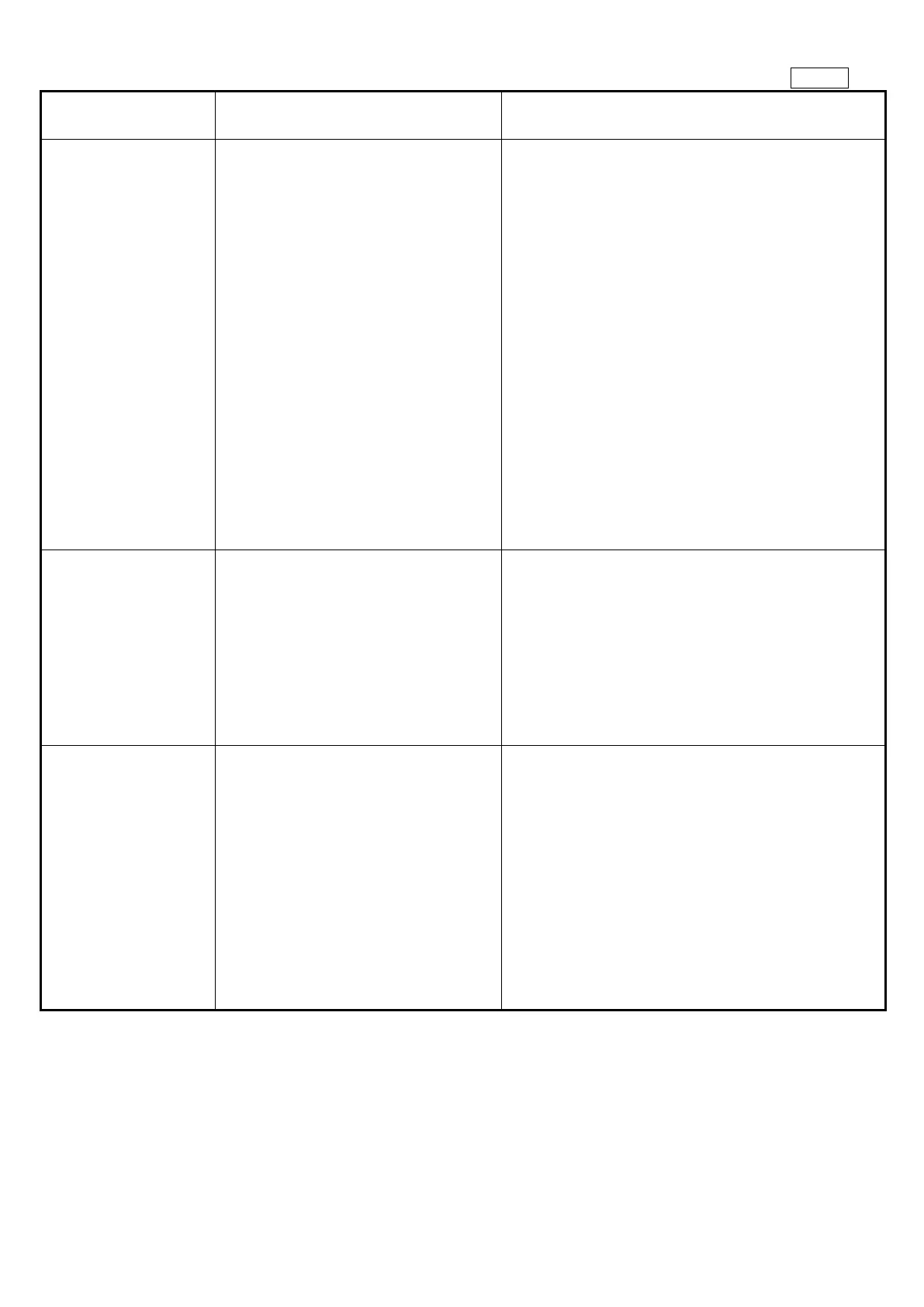

切削作業工件平

面不平、平行度

與直角度不正確

The cutting

surface not flat,

parallelism and

straightness not

correct

(1) 機台精密度不良

The accuracy of the

machine is no good.

(2) 鑲條密合度不夠

The gib do not fit with the

sliding way very well.

(3) 切削條件不夠

Cutting condition not

enough.

(4) 主軸軸承預壓不夠,螺帽

鬆脫

The pre-load of spindle

bearing not enough, screw

nut loosed.

(1) 檢驗精準度調整或刮花處理

Inspect the machine accuracy and

adjust it or scraping if required.

(2) 調整鑲條

Adjust the gib

(3) 刀具與切削進給與轉速、材料等須

配合

Tool must can be compare with the

cutting feed, spindle speed and

workpiece material.

(4) 調整軸承預壓,鎖緊螺帽 6098 或

6090

Adjust the spindle bearing’s

pre-load, lock the screw nut tightly

(#6098 or #6090).

伸出臂移動不順

暢

Ram moving

unsmooth

(1) 鑲條斷裂

Gib broken

(2) 齒條斷裂

Gear rack broken

(3) 潤滑不夠

Lubricant shortage

(1) 換鑲條

Replace gib.

(2) 換伸出臂

Replace ram.

(3) 去除表面油污注入潤滑油

Clean the dust and lubricate it.

自動鑽孔中主軸

停止或跳脫

Spindle stop or

trip during auto

drilling

(1) 進給離合器彈簧彈力不

足

The spring of the feed

clutch spring not enough.

(2) 切削條件不足

Cutting condition not

enough.

(1) 檢查進給條件或調整安全離器彈

簧較緊之壓力

Check feeding condition or adjust

the spring of the clutch to the tighter

pressure.

(2) 檢查刀具與切削時轉速與進給速

度

Check tool and spindle speed, feed

rate during cutting.

Loading...

Loading...