Check that all joints are securely tightened, test for leaks.

11

10

6

7

8

9

24

24 & 25

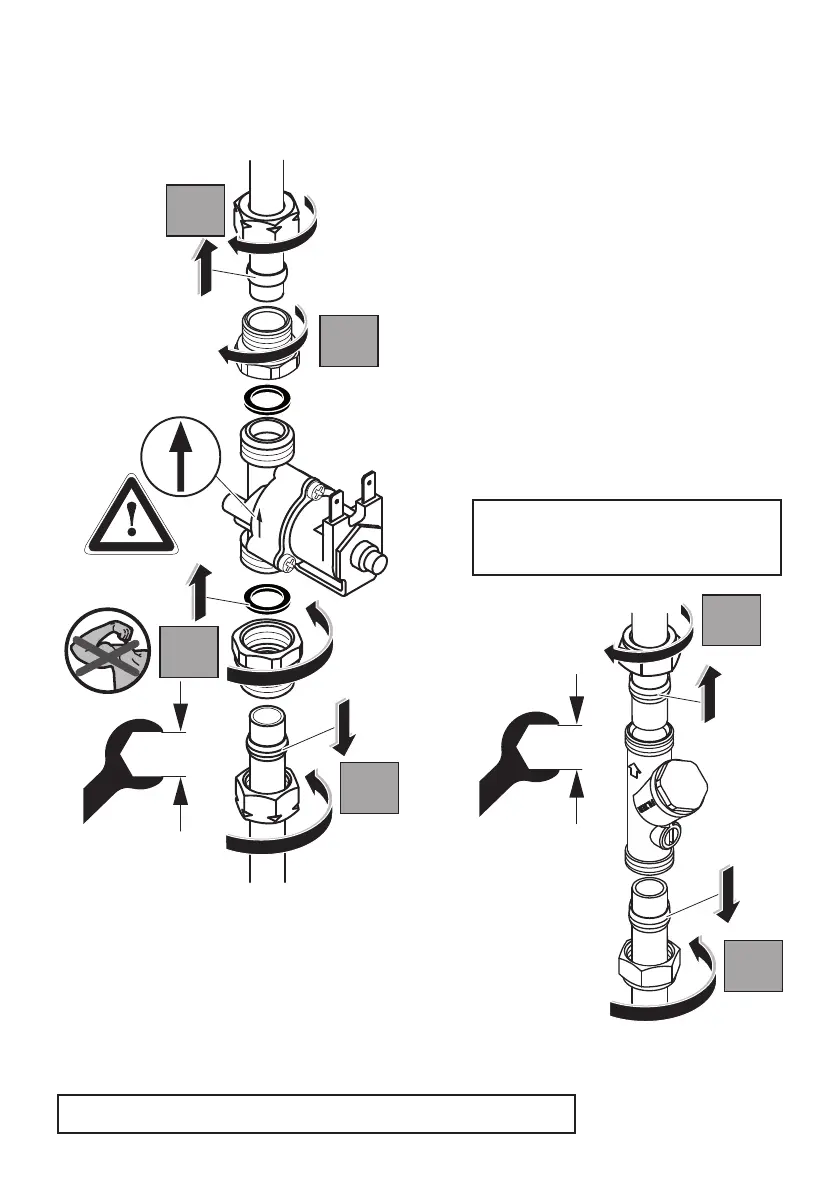

5. To t inlet adaptor cont: Slip the larger compression nut & olive onto a short length of Ø15mm

supply pipe. Push the supply pipe into the adaptor up to the shoulder. Slide the olive up to the adaptor

& tighten the compression nut with a 24mm A/F spanner. Hold the adaptor steady with a 22mm A/F

spanner.

6 & 8. To t solenoid valve:

The couplers can be screwed onto both sides

of the in-line solenoid valve. Ensure the seals

provided are tted as shown. Make good the

joints, taking care not to use excessive force.

Tighten with an adjustable spanner

(25mm A/F).

7 & 9. Slip the compression nuts & olives onto

the pipes. Fit the solenoid valve into the pipe-

work & make good the joints.

Observe ow direction.

Make sure the solenoid valve is orientated

such that the electrical connectors are easily

accessible.

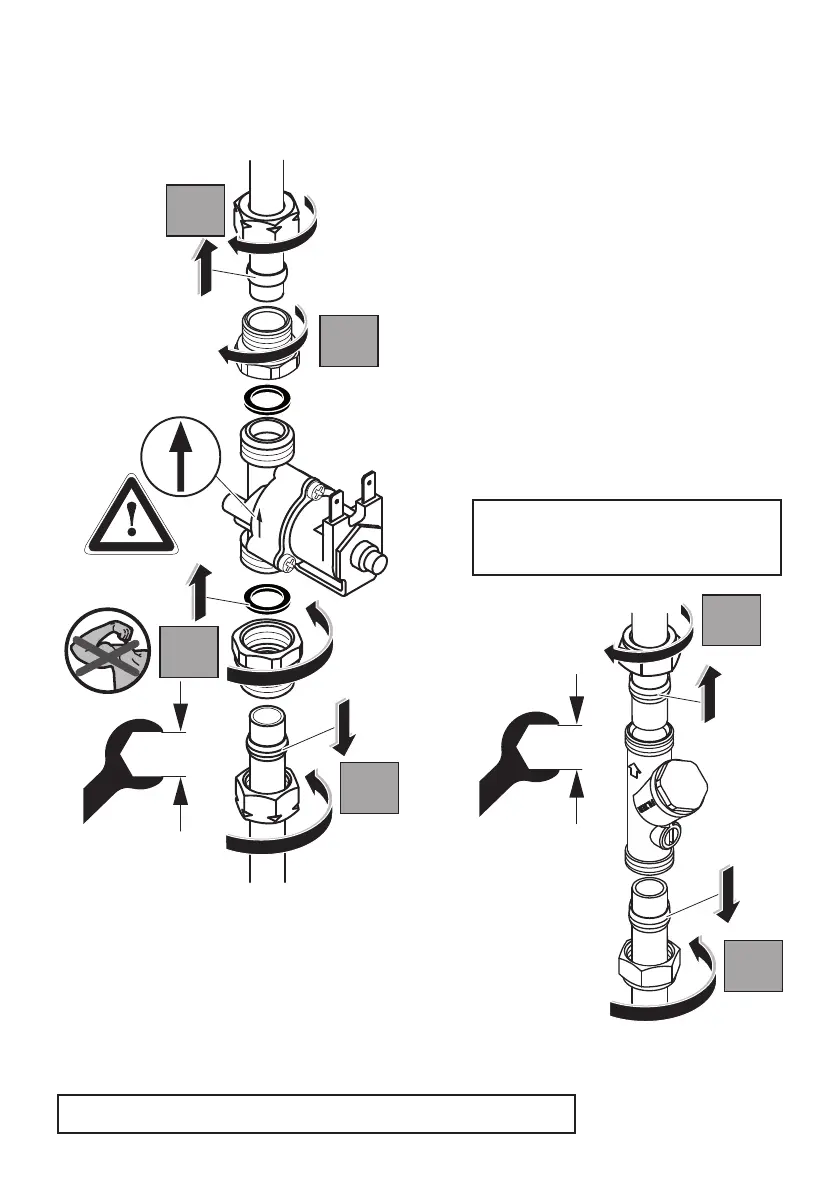

10 & 11. To t service valve:

Slip the compression nuts & olives onto the pipes. Fit the service valve

into the pipe-work & make good the joints. Observe ow direction.

Make sure the service valve is orientated such that the lter cap &

isolating screw are easily accessible for future maintenance.

When the isolator screw slot is parallel to the

valve body, the valve is open & permits water to ow.

To close the valve, rotate the isolator screw 90°.

8

NOTE FOR IRELAND: 15mm olives

are supplied with this product. Use

½” olives if ½” supply pipes are tted.

Loading...

Loading...