Ascon Tecnologic - Y33- Line - Operating Instructions - Pag. 8

8 PROBLEMS AND MAINTENANCE

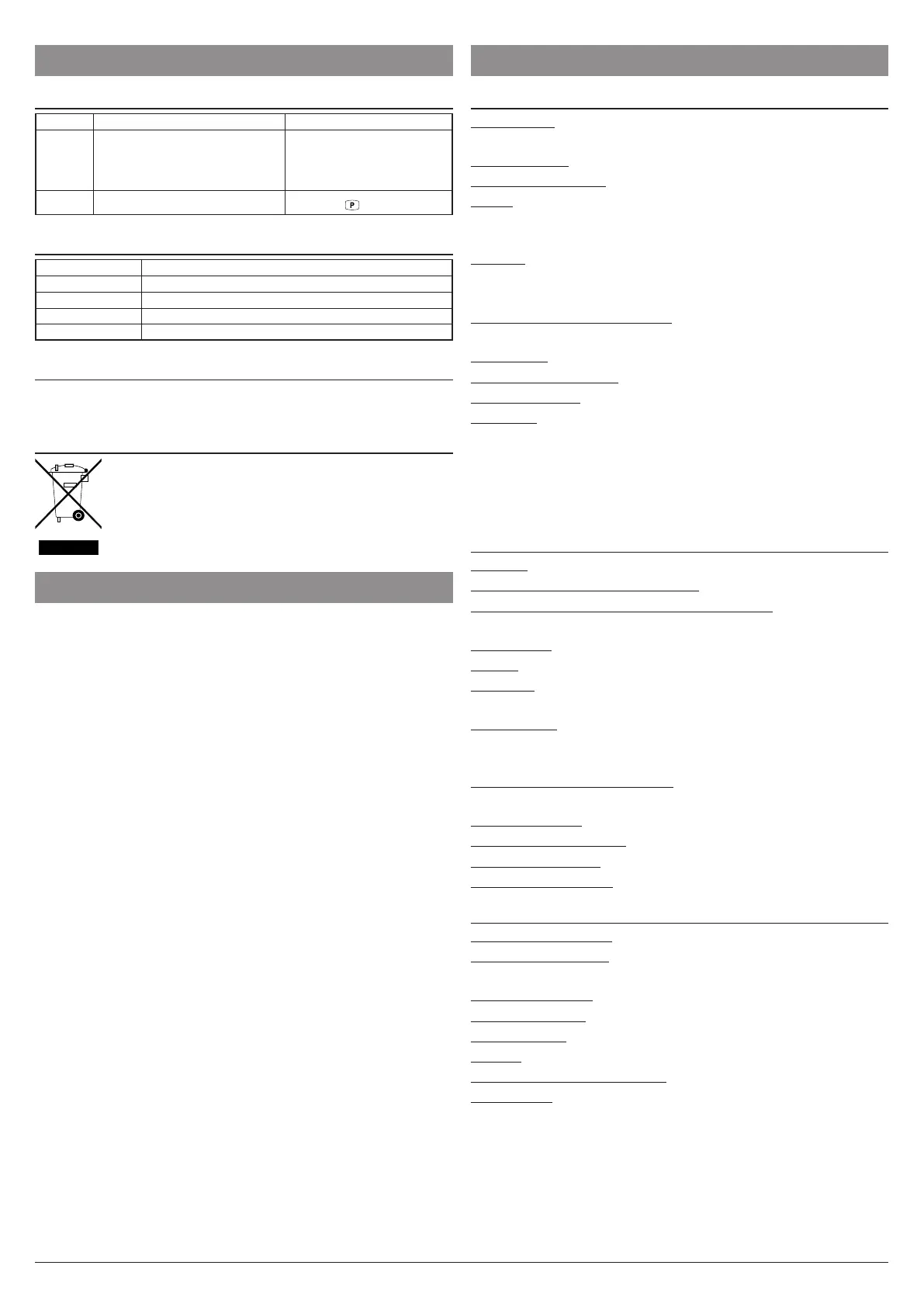

8.1 Error messages

Error Reason Action

E1 -E1

The probe may be interrupted

(E) or in short circuit (-E), or

may measure a value outside

the range allowed

Check the correct connec-

tion of the probe with the

instrument and check the

probe works correctly

EPr

Internal EEPROM memory error Press the

key

8.2 Other messages

Message Reason

od

Delay at power-on in progress

Ln

Keyboard lock

Hi

Maximum temperature alarm in progress

Lo

Minimum temperature alarm in progress

8.3 Cleaning

We recommend cleaning of the instrument only with a slightly

wet cloth using water and not abrasive cleaners or solvents.

8.4 Disposal

The appliance (or the product)

must be disposed of separately

in compliance with the local

standards in force on waste

disposal.

9 WARRANTY AND REPAIRS

The instrument is under warranty against manufacturing flaws or

faulty material, that are found within 18 months from delivery date.

The guarantee is limited to repairs or to the replacement of

the instrument.

The eventual opening of the housing, the violation of the instru-

ment or the improper use and installation of the product will

bring about the immediate withdrawal of the warranty’s effects.

In the event of a faulty instrument, either within the period of

warranty, or further to its expiry, please contact our sales de-

partment to obtain authorisation for sending the instrument

to our company.

The faulty product must be shipped to Ascon Tecnologic with

a detailed description of the faults found, without any fees or

charge for Ascon Tecnologic, except in the event of alterna-

tive agreements.

10 TECHNICAL DATA

10.1 Electrical Data

Power supply: 12 VAC/VDC, 12 ÷ 24 VAC/VDC, 100 ÷ 230 VAC

±10%;

AC Frequency: 50/60 Hz;

Power consumption: 4 VA approx.

Inputs: 1 input for temperature probes:

NTC (103AT-2, 10 kW @ 25°C) or

PTC (KTY 81-121, 990 W @ 25°C);

Outputs: 1 relay output SPDT or SPST-NO (16A-AC1,

6A-AC3 250 VAC, 1 HP 250 VAC, 1/2HP 125 VAC);

12 A Max. for screw removable terminal block model;

Electrical life for relay outputs: SPST-NO: 100000 operations,

SPDT: 50000 operations (VDE approval);

Action type: type 1.B (EN 60730-1);

Overvoltage category: II;

Protection class: Class II;

Insulation: Reinforced insulation between the low voltage

part (H type supply and relay output) and front panel; Re-

inforced insulation between the low voltage section (H type

supply and relay output) and the extra low voltage section

(inputs); Reinforced between supply and relay output; No

insulation between supply F or G type and inputs.

10.2 Mechanical Data

Housing: Self-extinguishing plastic, UL 94 V0;

Heat and fire resistance category: D;

Ball Pressure Test as described in EN60730: Accessible

parts 75°C, support live parts 125°C;

Dimensions: 78 x 35 mm, depth 64 mm;

Weight: 120 g approx.;

Mounting: Incorporated Flush in panel (thickness 12/29 mm

max.) in 71 x 29 mm hole;

Connections: 2.5 mm

2

screw terminals block or 2.5 mm

2

removable screw terminals block for 0.2 ÷ 2.5 mm

2

/

AWG 24 ÷ 14 cables;

Front panel protection degree: IP65 (NEMA 3S) mounted

with optional screw type bracket;

Pollution degree: 2;

Operating temperature: 0 ÷ 50°C;

Operating humidity: < 95 RH% with no condensation;

Storage temperature: -25 ÷ +60°C.

10.3 Functional Features

Temperature Control: ON/OFF mode;

Measurement range: NTC: -50 ÷ 109°C/-58 ÷ 228°F,

PTC: -50 ÷ 150°C/-58 ÷ 302°F;

Display resolution: 1° (or 0.1° in the range -99.9 ÷ +99.9°);

Overall accuracy: ±(0.5% fs + 1 digit);

Sampling rate: 130 ms;

Display: 3 Digit Red (Blue optional) h 15.5 mm;

Software class and structure: Class A;

Compliance: Directive 2004/108/CE (EN55022: class B;

EN61000-4-2: 8kV air, 4KV cont.; EN61000-4-3: 10V/m;

EN61000-4-4: 2kV supply and relay outputs, 1kV inputs;

EN61000-4-5: supply 2kV com. mode, 1kV\ diff. mode;

EN61000-4-6: 3V),

Directive 2006/95/CE (EN 60730-1, EN 60730-2-9).

Loading...

Loading...