10 m-radialdiaphragmvalve-en-02

6 Diaphragm selection

Diaphragm materials must be selected with consideration to heat-resistance, chemical-

resistance, steam-resistance, durability and handling as well as the number, temperature

and duration of CIP/SIP cycles. It is critical that you select the appropriate diaphragm

materials for your process. For material specifications and further information or assistance

with material selection, visit www.wmftg.com or contact your local sales office.

Ensure the chemicals to be used with valve assembly are compatible

with the valve body, actuator, diaphragm, to be used in the fluid path.

If you need assistance please contact your local sales office.

Examine the diaphragm at least once a week for signs of wear. If you have any concerns

with the condition of the diaphragm, contact your local sales office.

Diaphragm replacement

It is best practice to replace a diaphragm:

• At least annually - For fewer than five SIP cycles a week that are less than two hours

each at less than 135C

• At least every six months - For five or more SIP cycles a week that are less than

two hours each at less than 135C.

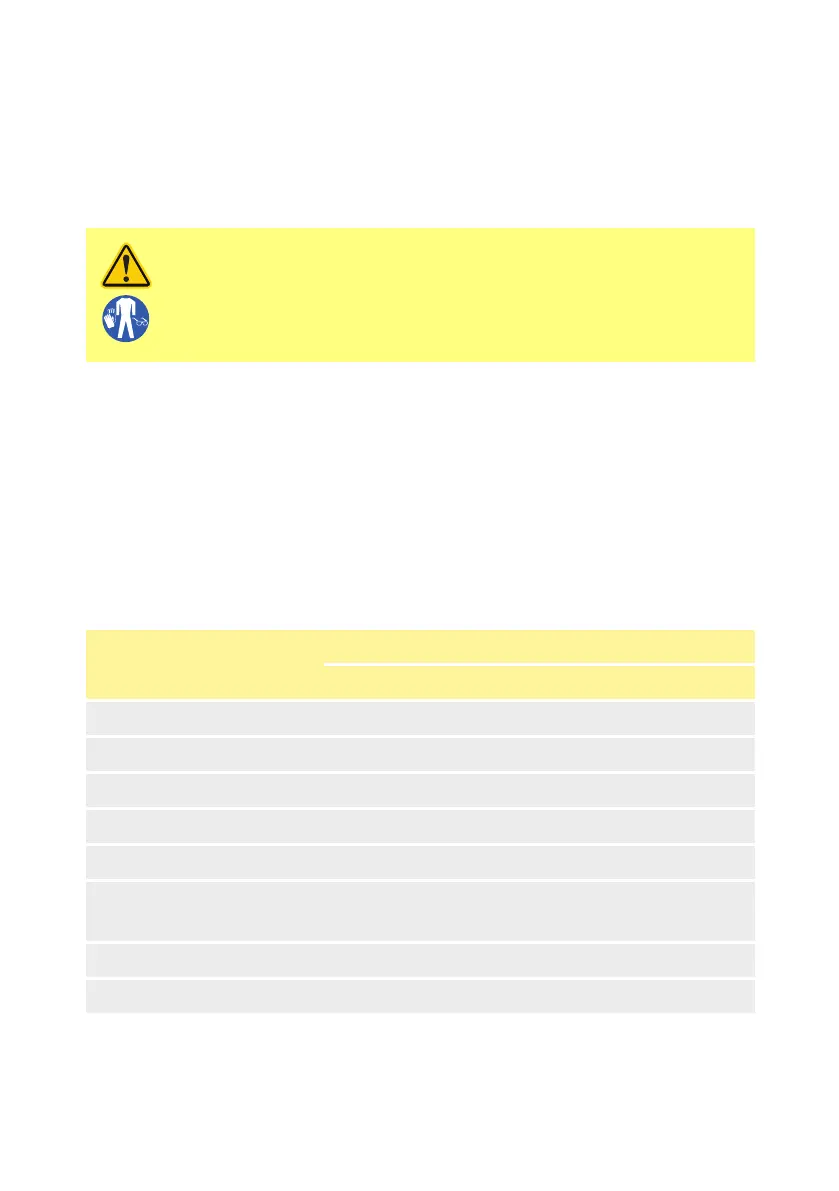

The following table summarises the availability of each diaphragm material for the

different valve sizes.

Material

Valve Size Availability

0.5" 1" 1.5" 2" 3" 4"

Silicone

u u u u u u

Silicone Plus

u u u u u

n/a

EPDM

u u u u u u

EPDM Plus

u u u u u

n/a

Viton A

u u

n/a

u

n/a n/a

Viton A

(steam resistant)

u u u u u

n/a

Viton GF n/a

u

n/a

u u

n/a

PTFE n/a

u u u u

n/a

Loading...

Loading...