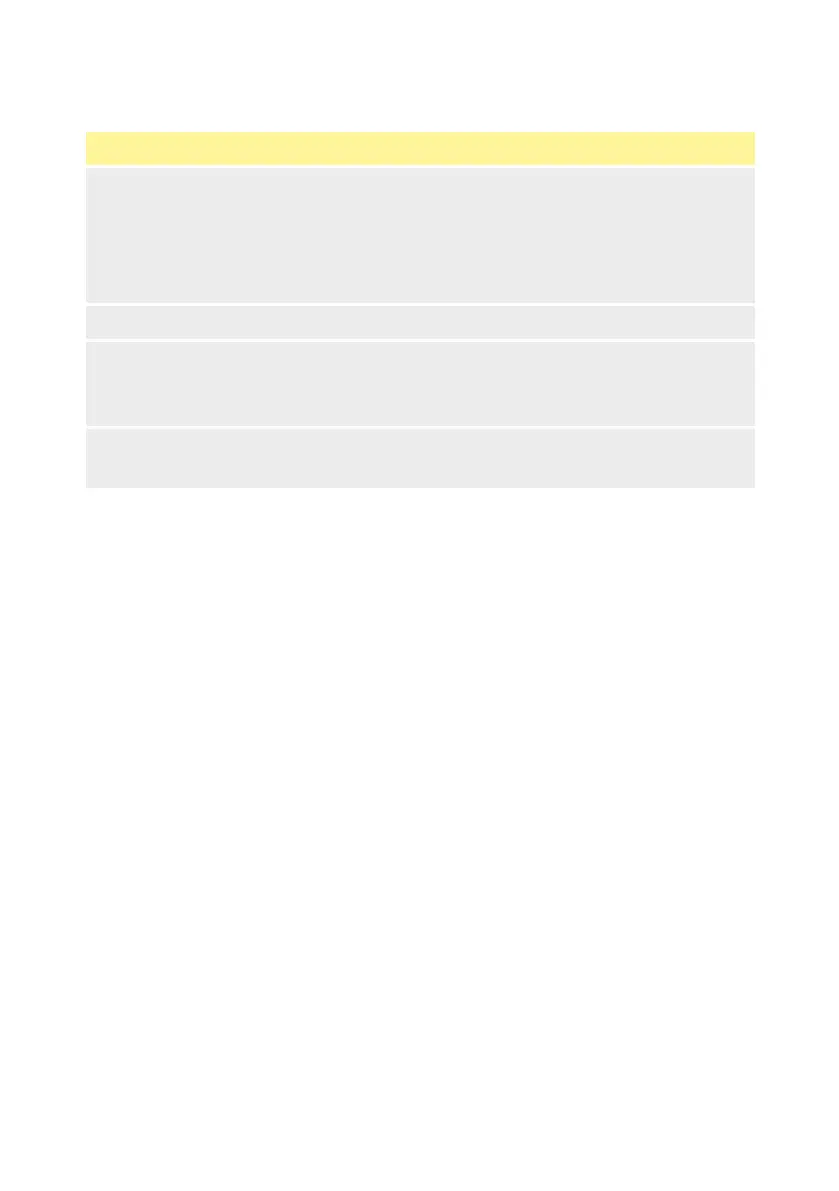

11 Troubleshooting

Issue Possible Causes

Leaking process fluid

• Clamp incorrectly installed onto valve

• Actuator seal failure

• Diaphragm failure

• Diaphragm not screwed on fully

• Valve damage

Leaking air • Actuator seal failure

Can’t open/close valve

fully

• Actuator failure

• Diaphragm failure

• Diaphragm not screwed on fully

Valve sticking or stuck

• Sticky diaphragm

• Actuator problem

Valve body issues

The most common valve body issues are:

• Valve damage - If you are having issues with leaking around the valve, inspect the

valve carefully for damage.

• Leaking diaphragm - If the clamp is not installed correctly, the diaphragm can leak

because of poor seating. Follow the assembly instructions carefully.

Actuator issues

The most common actuator issues are:

• Seal failure or leaking seal in a pneumatic actuator - The operator usually hears air

leaking from the valve during operation. In addition, the valve may not fully open or

close.

• Bends or damages the actuator shaft or handle caused by dropping the valve

assembly or actuator - When this occurs, the bent shaft or damaged handle may

keep the diaphragm from seating properly, resulting in process fluid leakage.

• Bent or improperly assembled actuator - If the valve does not assemble easily,

examine it carefully for damage. Do not force the valve together.

• The valve is not opening or closing easily - Double check the actuator to make sure

that it is assembled properly.

Diaphragm issues

Diaphragms are the high-wear components of valves and the most common point of failure.

Common causes of diaphragm failure are:

• Incorrect assembly - A diaphragm can wear prematurely if it isn’t installed properly

on the actuator and in the valve body.

• Actuator failure - Lack of servicing a pneumatic actuator can lead to a catastrophic

diaphragm failure. Actuators don’t need to be serviced often, but every year or so,

m-radialdiaphragmvalve-en-02 35

Loading...

Loading...