42 m-radialdiaphragmvalve-en-02

Tack Welding from OUTSIDE the vessel head

13.8 Final external welding of the tank valve

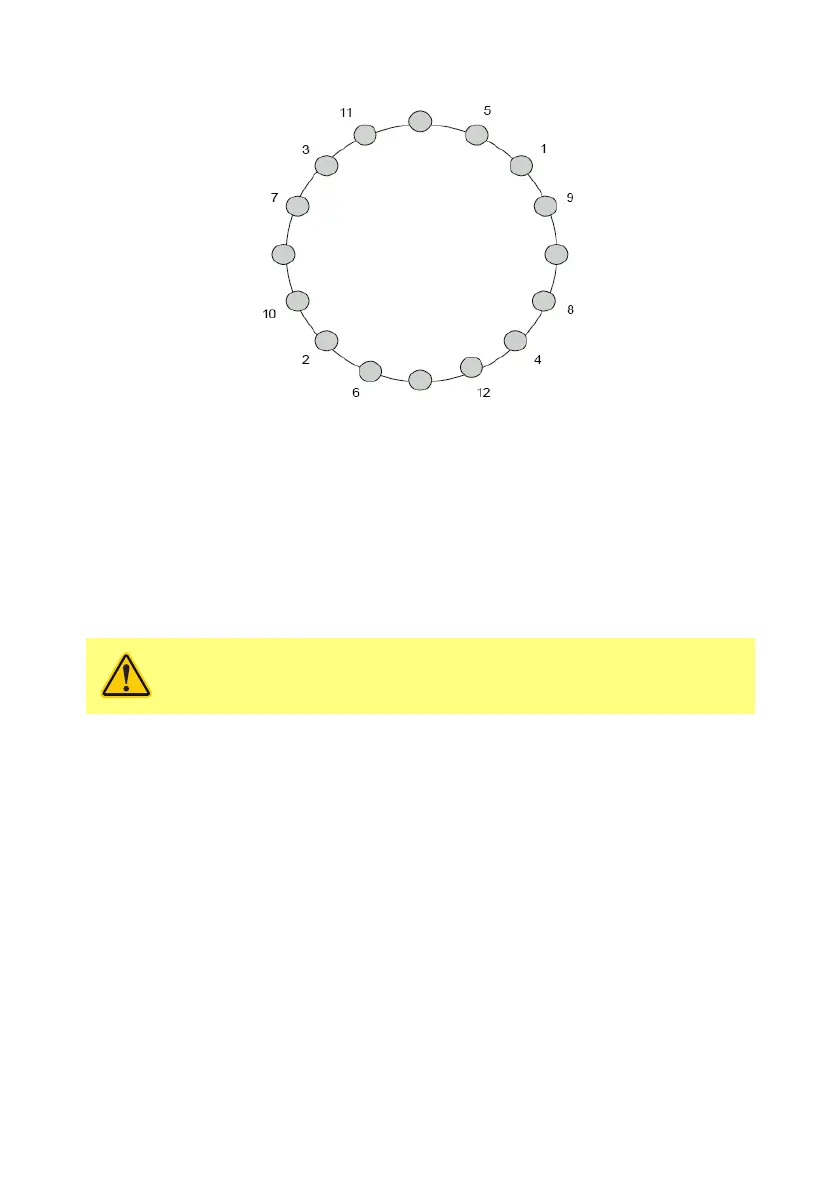

1. Using the appropriate filler material weld the tank valve in the progression as shown

below.

2. Always weld in a clockwise movement from tack to tack.

3. Cool the weld zone to 25C (80F) after each weld using compressed air.

4. Repeat the welding process identified in steps 1-3 above until the weld profile is

shaped like a fillet weld with no undercut present.

Follow above instructions. Do not overheat the material.

Loading...

Loading...