Hydraulic oil

In order to protect the environment, use of

biologically degradable hydraulic oil is

recommended. No other fluids must be used.

◆

Viscosity (preferred) 20-40 cSt.

◆

Viscosity (permitted) 15-100 cSt.

◆

Viscosity index minimum 100.

Standard mineral or synthetic oil can be used.

Make sure to only use clean oil and filling

equipment.

When the machine is used continuously, the oil

temperature will stabilise at a level which is called

the working temperature. This will, depending on

the type of work and the cooling capacity of the

hydraulic system, be between 20-40°C (68-104°F)

above the ambient temperature. At working

temperature, the oil viscosity must be within the

preferred limits. The viscosity index indicates the

connection between viscosity and temperature. A

high viscosity is therefore preferred, because the

oil can then be used within a wider temperature

range. The machine must not be used, if oil

viscosity fails to remain within the permitted area,

or if the working temperature of the oil does not fall

between 20°C (68°F) and 70°C (158°F).

NOTICE The setting of the pressure relief valve

on the machine can in some cases be higher than

the prescribed maximum setting according to the

EHTMA category, see "EHTMA category". A too

high pressure relief valve setting can harm the

machine to be used. Readjust the pressure relief

valve, if the technical specifications of the machine

prescribe a lower pressure relief valve setting than

the standard setting of the machine.

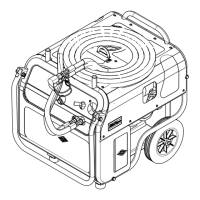

Hydraulic control and

connectors

The by-pass valve (C) must be in the OFF position

when starting and in the ON position when using

the machine.

Connectors (G) and (H) are used to connect the

power pack to the machine as follows:

◆

Connector (G) = Return (female quick-release

coupling).

◆

Connector (H) = Feed (male quick-release

coupling).

Hoses and connections

Ensure that the machine you plan to use is

compatible with the model of power pack being

used. Otherwise, both the power pack and the

machine might be harmed. Check the "Technical

data" in this instruction book and compare the flow

rate with the technical specifications in the

instruction book for the machine.

Connecting hoses

1. Turn the by-pass valve to the OFF position and

stop the engine.

2. Make sure the couplings are clean and

serviceable.

3. Attach the return line hose and the feed line

hose.

4. Start the engine and run the power pack to fill

up the hydraulic circuit. Check the hydraulic oil

level.

Disconnecting hoses

1. Turn the by-pass valve to the OFF position and

stop the engine.

2. Remove the feed line hose and the return line

hose.

The couplings are unlocked by moving the collar

back on the coupling.

Hose length

For power packs giving a flow of 20 l.p.m. (5 US

gal/min), a maximum hose length of 21 m (69 ft) is

recommended. For power packs giving a higher

flow, a maximum hose length of 14 m (46 ft) is

recommended.

Normally, 7 m (23 ft) of Twin hose is used for the

power pack.

Twin hoses and other accessories are shown in

the spare parts list.

Safety and operating instructions LP 13-30 P

12 © Construction Tools EOOD | 3392 5254 01 | 2017-04-13

Original instructions

Loading...

Loading...