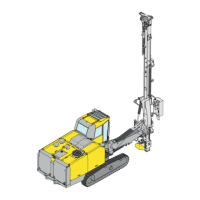

Do you have a question about the Atlas Copco SmartROC T45 and is the answer not in the manual?

Explains the manual's objective to prevent accidents and property damage.

Addresses hazards related to stored energy in machine components and systems.

Identifies burn hazards from hot surfaces like particle filters and exhaust pipes.

Warns about entanglement and shearing risks from rotating and moving parts.

Details crushing hazards posed by movable boom system parts.

Highlights tipping risks during transport and exceeding inclination angles.

Covers scalding hazards from high liquid temperatures and pressure.

Warns about tipping, sliding, or whipping risks due to winch cable breakage.

Addresses hazards from leaking fluid systems causing injection and flesh erosion.

Defines hazard zones around the machine during tramming and drilling operations.

Provides fundamental safety rules for operating and working with the machine.

Lists essential personal protective equipment (PPE) and safety practices for operators.

Covers critical safety practices to observe during machine operation.

Specifies safety procedures to follow during service and maintenance activities.

Introduces the emergency stop function and its importance for machine safety.

Shows the locations of various emergency stop buttons and cables on the drill rig.

Explains the procedure for resetting the emergency stop after it has been activated.

Describes the protective guard fitted on the feeder for enhanced operational safety.

| Hydraulic System Pressure | 250 bar |

|---|---|

| Feed Force | 28 kN |

| Compressor Type | Screw type |

| Control System | RCS (Rig Control System) |

| Engine Power | 242 kW |