12 1310 3011 08

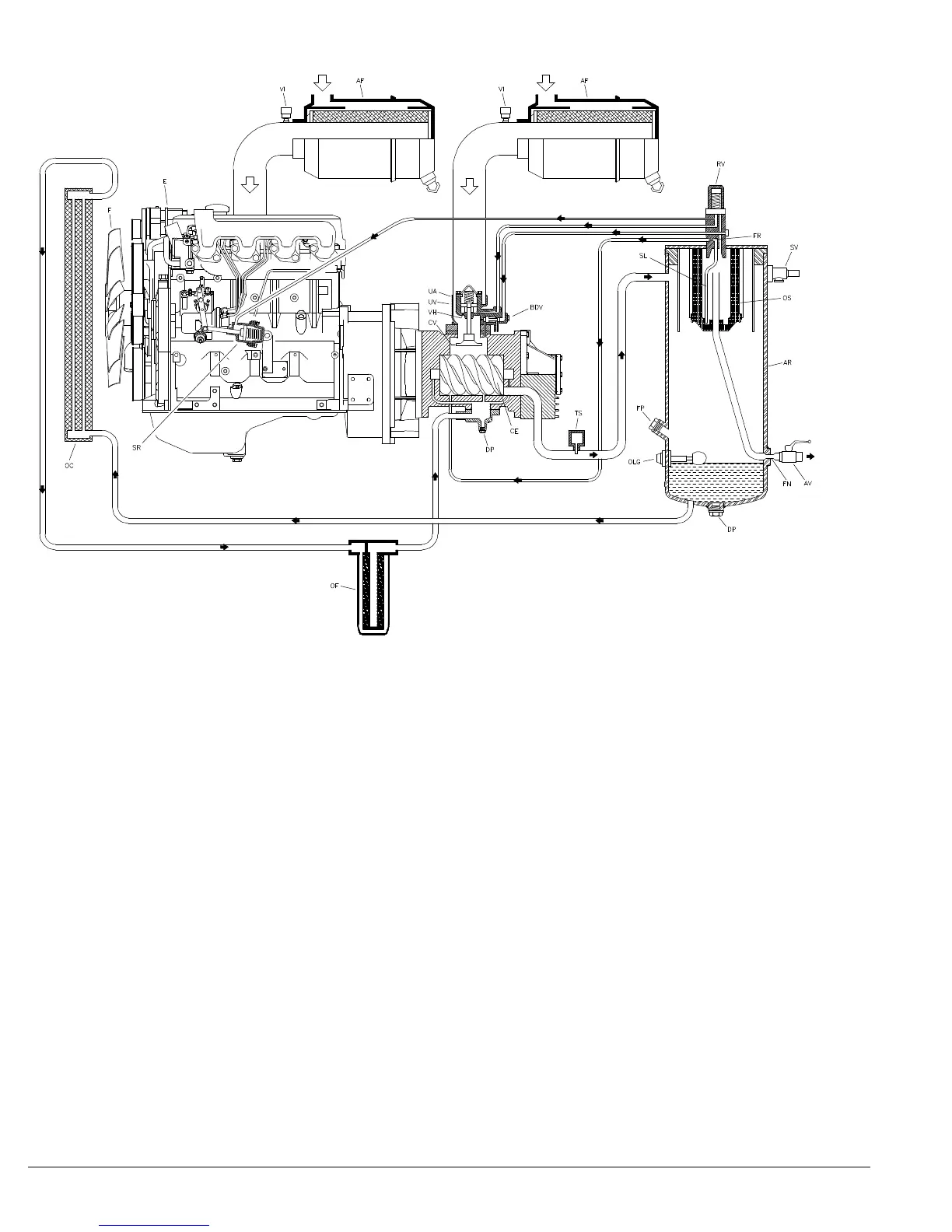

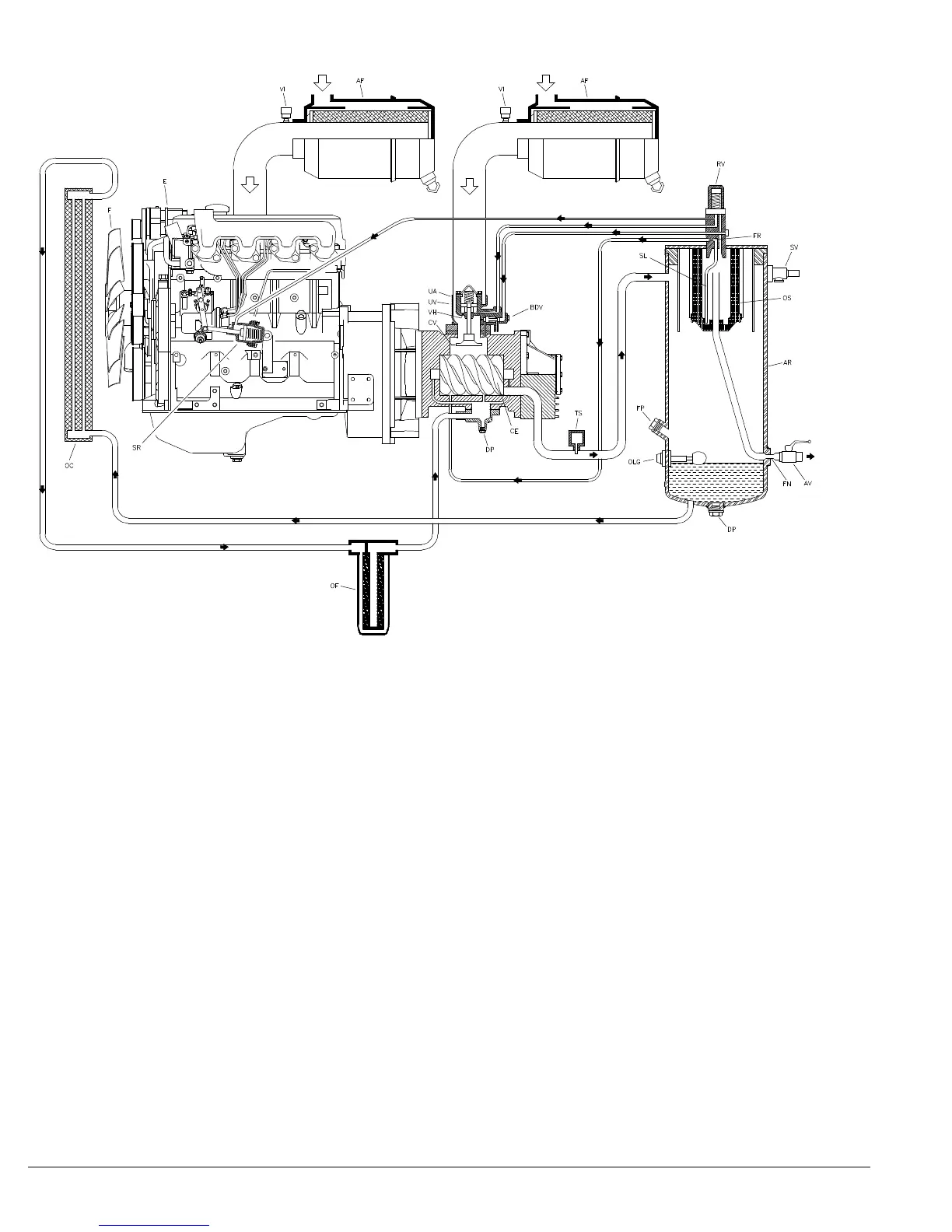

Fig. 2.3 Compressor Regulating System

AF Air Filter

AR Air Receiver

AV Air Outlet Valves

BDV Blow Down Valve

CE Compressor Element

CV Check Valve

DB Drive Belt

DP Drain Plug

E Engine

F Fan

FN Flow Nozzle

FP Filling Plug

FR Flow Restrictor

OC Oil Cooler

OF Oil Filter

OLG Oil Level Gauge

OS Oil Separator

PG Pressure Gauge

RV Regulating Valve

SL Scavenge Line

SR Speed Regulator

SV Safety Valve

TS Temperature Switch

UA Unloader Assembly

UV Unloader Valve

VH Vent Hole

VI Vacuum Indicator

2.4 Air Flow (See Fig. 2.3)

The system comprises:

AF Air filter

AR/OS Air receiver/oil separator

CE Compressor element

UA/UV Unloader assembly with unloader valve

BDV Blow-down valve

FN Flow nozzle

Air drawn through the airfilter (AF) into the compressor

element is compressed. At the element outlet, compressed

air and oil pass into the air receiver/oil separator (AR/OS).

The check valve prevents blow-back of compressed air when the

compressor is stopped. In the air receiver/oil separator AR//OS),

most of the oil is removed from the air/oil mixture: the remaining

oil is removed by the separator element.

The oil collects in the receiver and on the bottom of the separator

element.

The air leaves the receiver via a flow nozzle (FN) which prevents

the receiver pressure from dropping below the minimum working

pressure, even when the air outlet valves are open. This ensures

adequate oil injection and prevents oil consumption.

A temperature switch (TS) and a working pressure gauge (PG) are

comprised in the system.

A blow-down valve (BDV) is fitted in the unloader assembly to

automatically depressurize the air receiver (AR) when the

compressor is stopped.

Loading...

Loading...