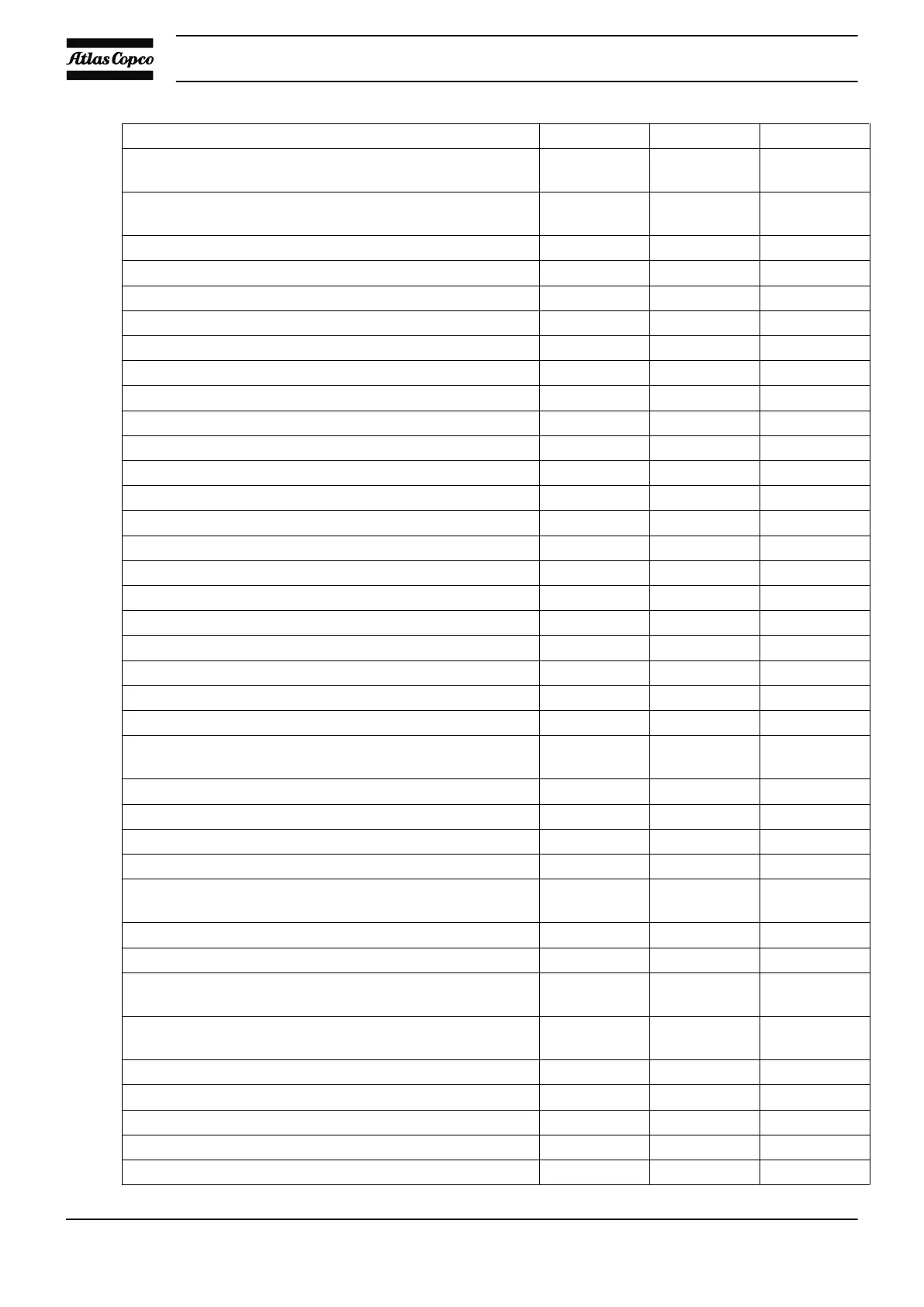

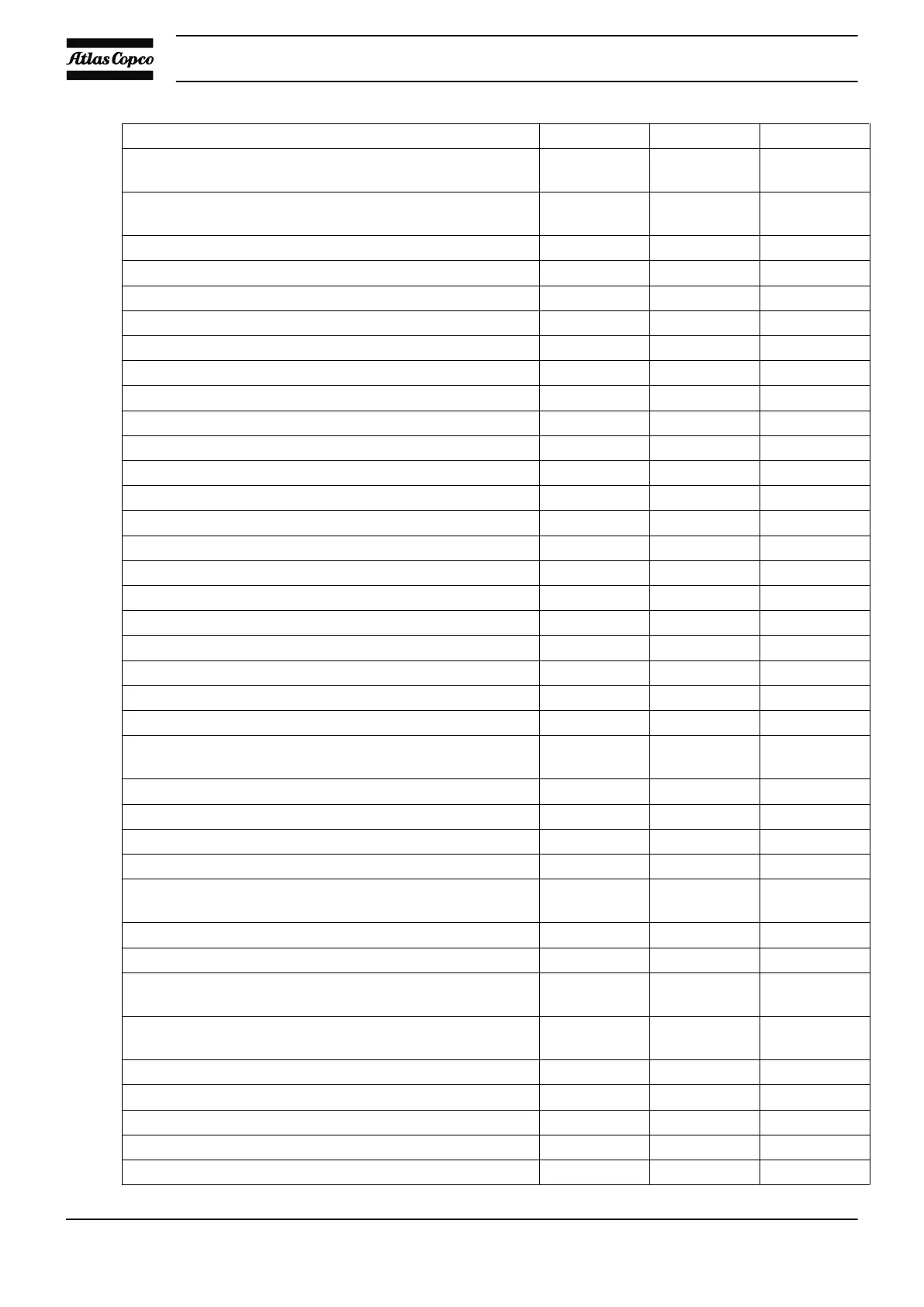

Activities Level A Level B Level C

Take service readings (air, oil, water temperature and

pressure)

X X X

Check cooler functions (approach temperature) and clean if

necessary

X X X

Change intercooler condensate check valve X X X

Check intercooler blowdown valve X X X

Check for air, water and oil leakage X X X

Check critical bolt/coupling connections X X X

Check operation of safety valves X X X

Check for presence of water in lube oil X X X

Change Roto Z oil (16000 hrs or 2-yearly) - - X

Inspect/change air filter element(s) X X X

Check condition of air intake chamber X X X

Change compressor oil filter (8000 hrs or annually) - X X

Replace filter element of gear case breather X X X

Check cycle of air intake throttle valve X X X

Replace diaphragm of air throttle valve X X

Overhaul air intake valve X

Check functioning of check valve (8000 hrs or annually) X X X

Overhaul check valve X

Check condition of balance piston diaphragm X X -

Change balance piston diaphragm - X X

Check/Service condensate drain(s) X X X

Overhaul drain(s) - X X

Grease main drive motor bearings (according to motor data

plate)

X X X

Clean fan cowl of electric motor X X X

Check rubber inserts of drive coupling (arr. E) X X

Replace inserts of drive coupling (arr. E) X

Check condition of drive gear teeth X X

Take and record all S.P.M. readings. On VSD compressors

also register the motor speed

X X X

Inspect electrical contactors X X X

Check all electrical connections X X

On VSD compressors, if applicable, replace motor carbon

brush

X

On VSD compressors, if necessary, clean electrical cabinet

with vacuum cleaner

X X X

Check oil quantity X X X

Replace shaft seal - - X

Replace the demister sponge of the integrated dryer - - X

Inspect the dryer heater - - X

Inspect the dryer rotor - - X

Instruction book

284 2920 1815 04

Loading...

Loading...