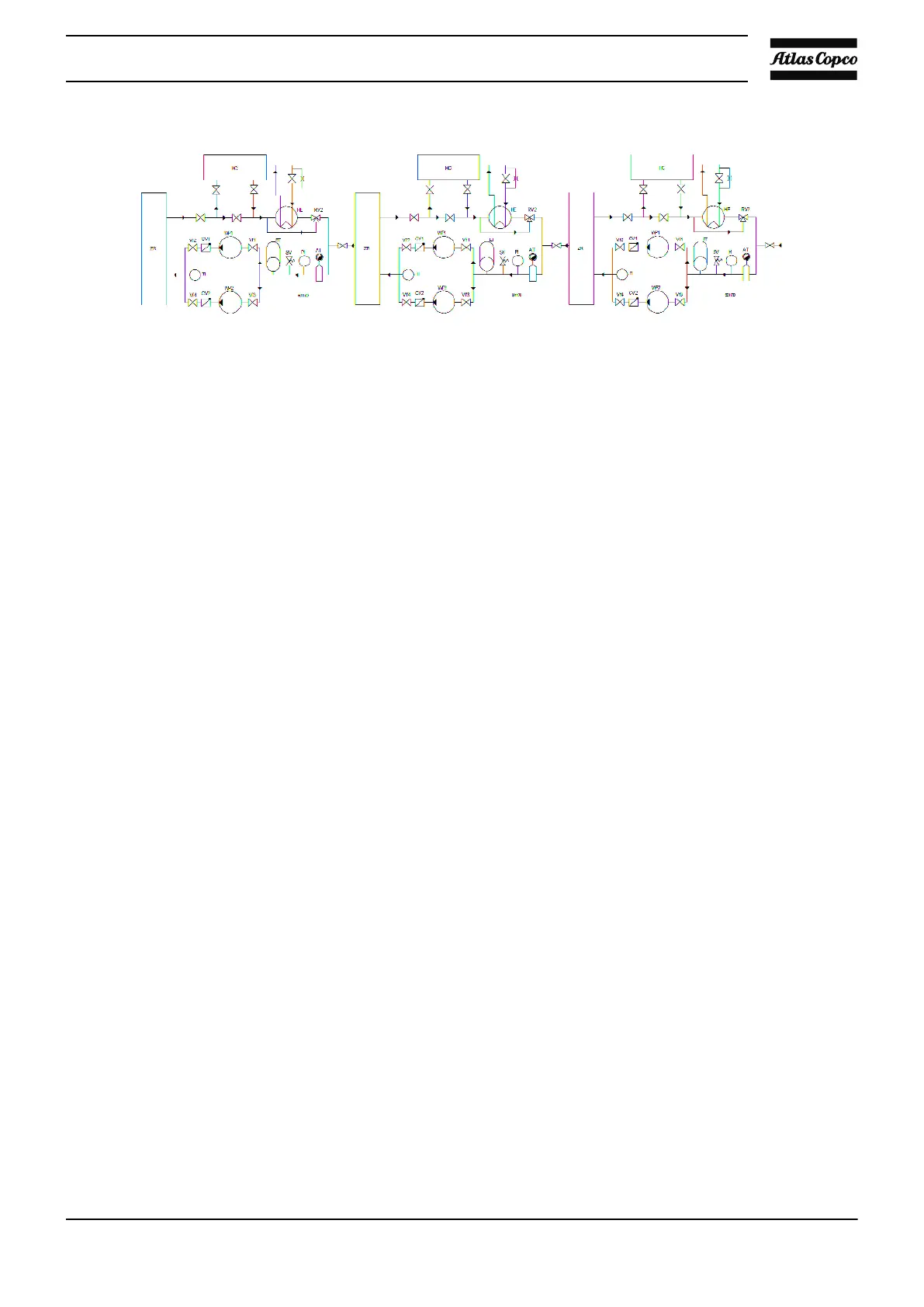

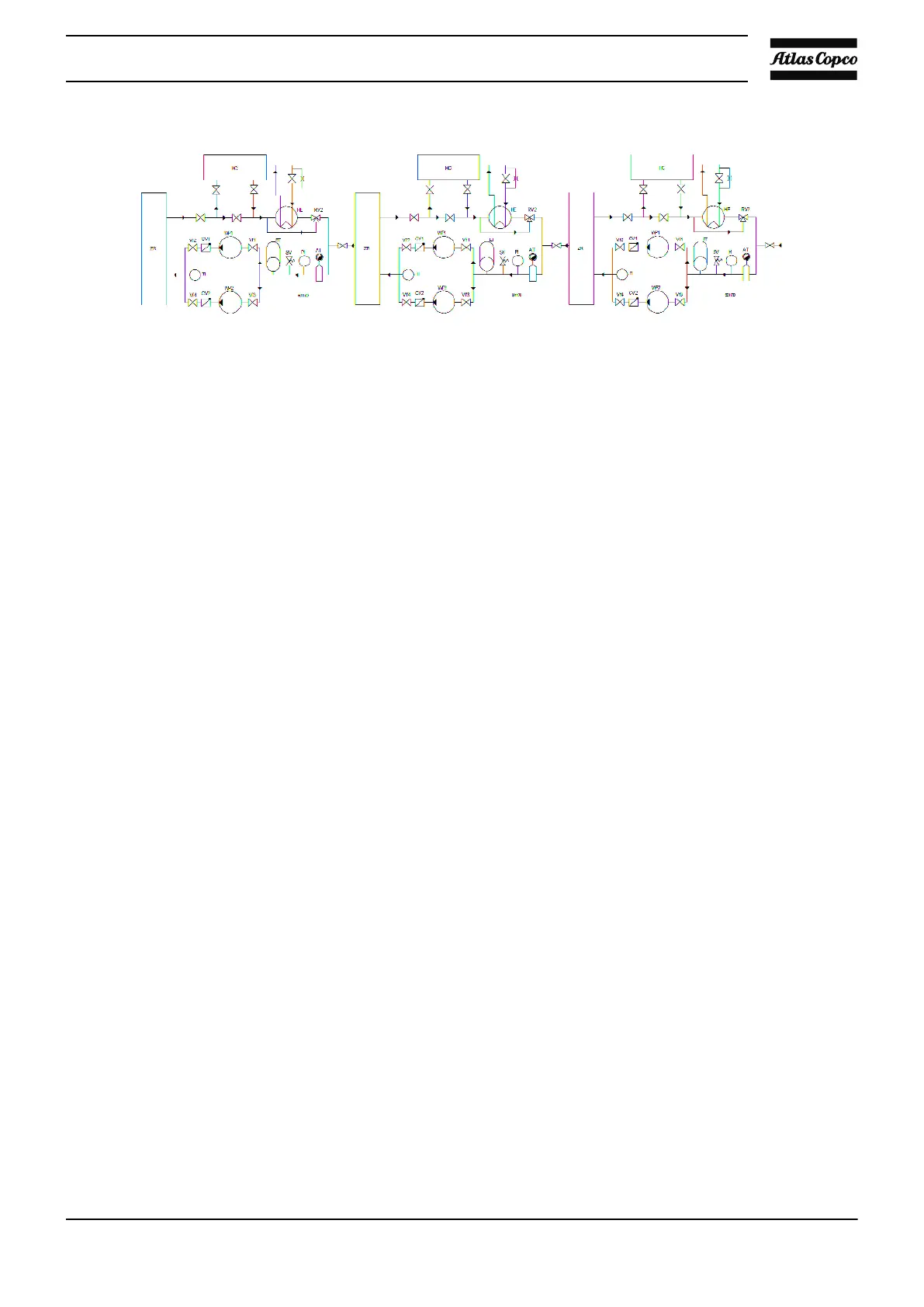

Pump unit

Atlas Copco supplies pump units to transfer the energy recovered from the compressor to the heat

consumer (HC). The pump unit constitutes a closed water circuit with the compressor cooling system.

Two water pumps (WP1/2) are fitted. One pump circulates the hot cooling water from the compressor

through the heat consumer and back to the compressor. The other is a stand-by pump. Check valves

(CV1/2) at the delivery side of the pumps prevent backflow of water in the stand-by pump. The pump unit

is fitted with a make-up water connection, an air trap with automatic de-aeration device (AT), a pressure

and temperature gauge (PI and TI), a safety valve (SV) and an expansion tank (ET).

Cooling water requirements

Closed recirculating water systems minimize make-up water requirements. Therefore, it is economically

feasible to use softened water to eliminate the problem of scaling deposits.

Corrosion control is important. The best results are obtained by adding corrosion inhibitors as used in

engine cooling systems.

Using anti-freeze products is an alternative solution to avoid problems, e.g. adding 20 % to 30 % ethylene-

glycol based anti-freeze to the tap water.

For open cooling water systems (e.g. boiler feed water preparation), consult the Atlas Copco Customer

Centre to avoid problems related to deposit control, corrosion control and microbiological growth control.

Water flow regulation through heat exchangers

Depending on the amount of energy transferred in the heat consumer (HC), the heat exchanger (HE) of the

pump unit is completely or partly by-passed by means of a thermostatic valve (RV2). The valve is normally

adjusted to achieve a cooling water temperature of 40 ˚C (corresponding to the maximum allowable

Instruction book

2920 1815 04 37

Loading...

Loading...