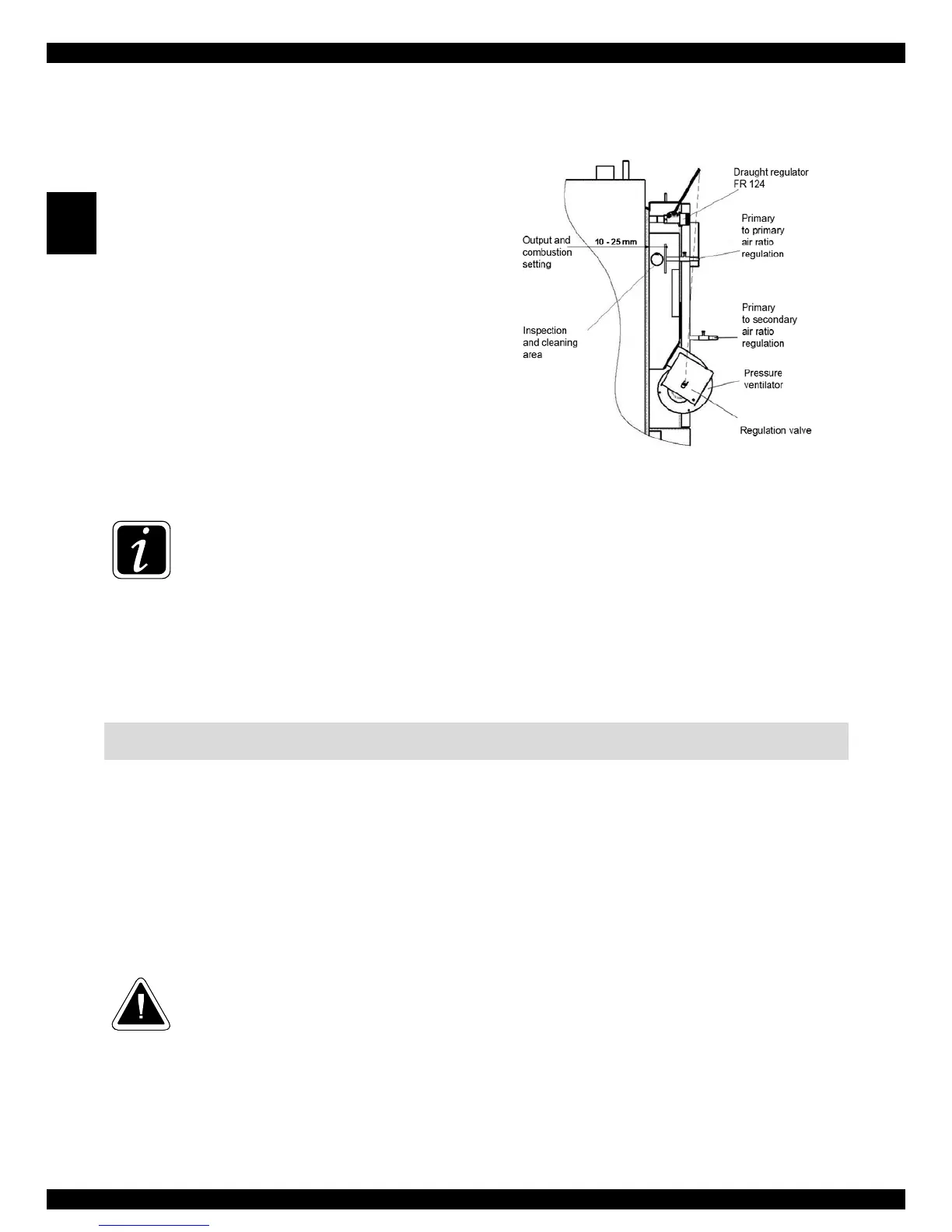

Boiler with compressive ventilator DC70S

Basic setting of primary air ratio:

Optimum setting:

fully closed (5 mm) + 8÷10 mm

Maximum setting:

fully closed (5 mm) + 10÷20 mm

Basic setting of secondary air ratio:

Optimum setting:

fully closed (8 mm) + 0 mm

Maximum setting:

fully closed (8 mm) + 5÷20 mm

Adjustments to settings should be done on the basis of the waste gas analyzer and maximum

temperature; which must not exceed 320 °C at the outlet to chimney, at stabilised nominal

output /with closed ignition valve/. The boiler is set to optimal operating parameters by the

manufacturer. Therefore, make adjustments to settings only in cases where the operation

conditions are non-standard (for example - if insufficient chimney draught, pull the regula-

tor pulling rod to its maximum).

29. Fuel refill

Before fuelling, open the ignition valve /13/ with the pulling rod /17/. Do not switch the extraction

ventilator off. Wait for approximately 10 seconds and slowly open the loading door /2/ so that any ac-

cumulated gases are first vented off into the flue-gas duct and not in the boiler room. Before opening

the DC70 door, switch the pressure ventilator /4/ off using switch /20/. Cover the glowing charcoals

with a wide log. Do not press the fuel on the gasifying nozzle, it can put the flame out. Always fill the

hopper completely. In order to prevent excessive smoke formation, load new batch of fuel only after

the previous fuel has combusted to at least one third of the loading volume.

CAUTION – during operation, the ignition valve pulling rod must be retracted, other-

wise damage to the ventilator (S) will occur. Otherwise, the ventilator (S) will sustain

damage.

Loading...

Loading...