4-2

4.1. PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS)

4.1.1. PURPOSE OF PMCS

PMCS is performed daily when in use to be sure that the sight is

readyatalltimes.ProcedureslistedinTable4-1areasystematic

inspection of

ThOR

that will enable you to discover defects that

might cause the sight to fail on a mission.

4.1.2. FREQUENCY OF PERFORMING PMCS

The frequency of performing PMCS is as follows:

A. Daily when the sight is in use.

B.Whenitisremovedfromthecaseforanyreason.

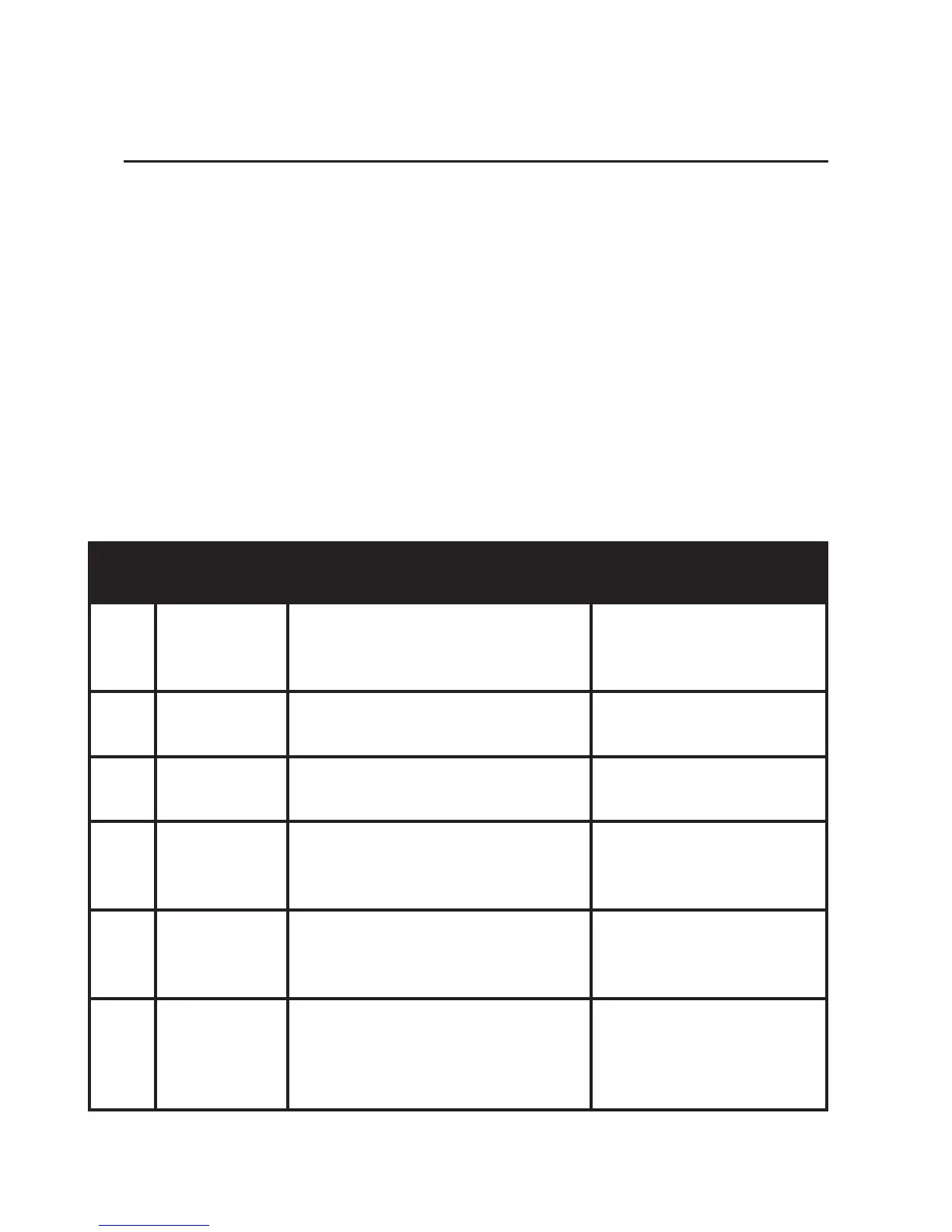

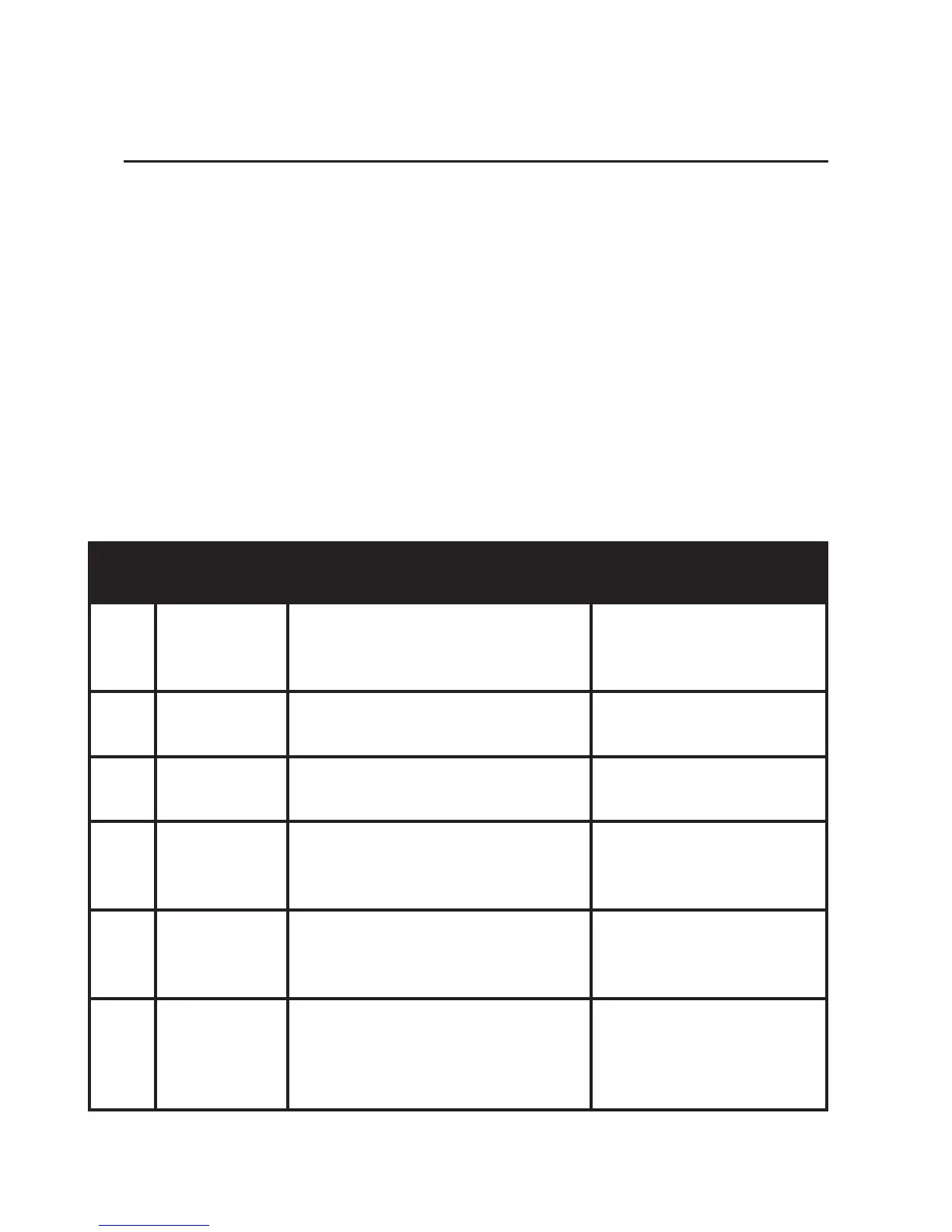

TABLE 4-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

SEQ.

NO.

ITEM TO

CHECK

CHECKING PROCEDURE

NOT FULLY MISSION

CAPABLE IF:

1

Complete-

ness

Inventory items by means

of comparing with the data

specified in this manual.

Items missing.

2 Sight Body

Inspect for missing screws

or connector cap.

Screws or connector

cap missing.

3

Front Lens

Cap

Inspect for cuts, tears and

dirt. Clean as required.

Cap torn or cut.

4

Battery

Compart-

ment

Check for corrosion, springs

tension.

Springs corroded or

damaged.

5

Reticle ad-

justment

knob

Check for operation (without

batteries).

Knobinoperative.

Knobmissing.

6 Lenses

Inspect for cleanliness,

scratches, chips or cracks.

Clean as required.

Chipped, cracked or

if scratches hinder

vision through the

sight.

Loading...

Loading...