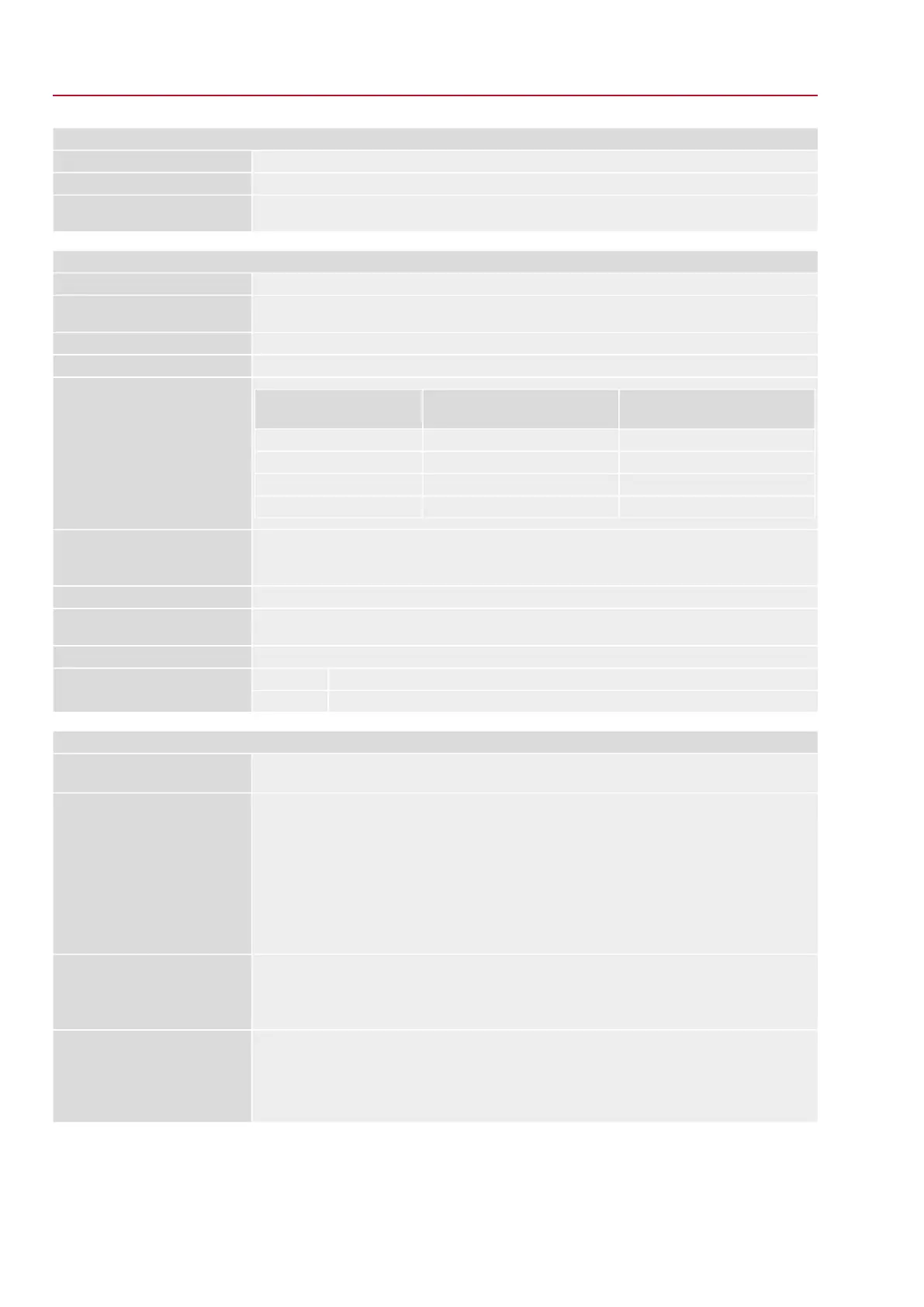

Settings/programming the Profibus DP interface

Automatic baud rate recognitionBaud rate setting

The Profibus DP address is set via the display of the device.Setting the fieldbus address

For an optimum adaptation to the process control system, the process representation input (feedback

signals) can be configured as desired.

Configurable process representation

via GSD file

General Profibus DP interface data

Profibus DP according to IEC 61158 and IEC 61784Communication protocol

Line (fieldbus) structure.When using repeaters, tree structures can also be implemented. Coupling and

uncoupling of devices during operation without affecting other devices is possible.

Network topology

Twisted, screened copper cable according to IEC 61158Transmission medium

EIA-485 (RS-485)Profibus DP interface

Possible cable length with repeater

(total network cable length):

Max. cable length

(segment length) without repeater

Baud rate (kbit/s)

approx. 10 km1,200 m9.6 – 93.75

approx. 10 km1,000 m187.5

approx. 4 km400 m500

approx. 2 km200 m1,500

Transmission rate/cable length

DP master class 1, e.g. central controllers such as PLC, PC, ...

DP master class 2, e.g. programming/configuration tools

DP slave, e.g. devices with digital and/or analogue inputs/outputs such as actuators, sensors

Device types

32 devices without repeater, with repeater expandable to 126Number of devices

Token-passing between masters and polling for slaves. Mono-master or multi-master systems are pos-

sible.

Fieldbus access

Cyclic data exchange, sync mode, freeze mode, fail safe modeSupported Profibus DP functions

Standard applications with Profibus DP-V0 and DP-V10x0C4F:Profibus DP ident no.

Applications with Profibus DP-V20x0CBD:

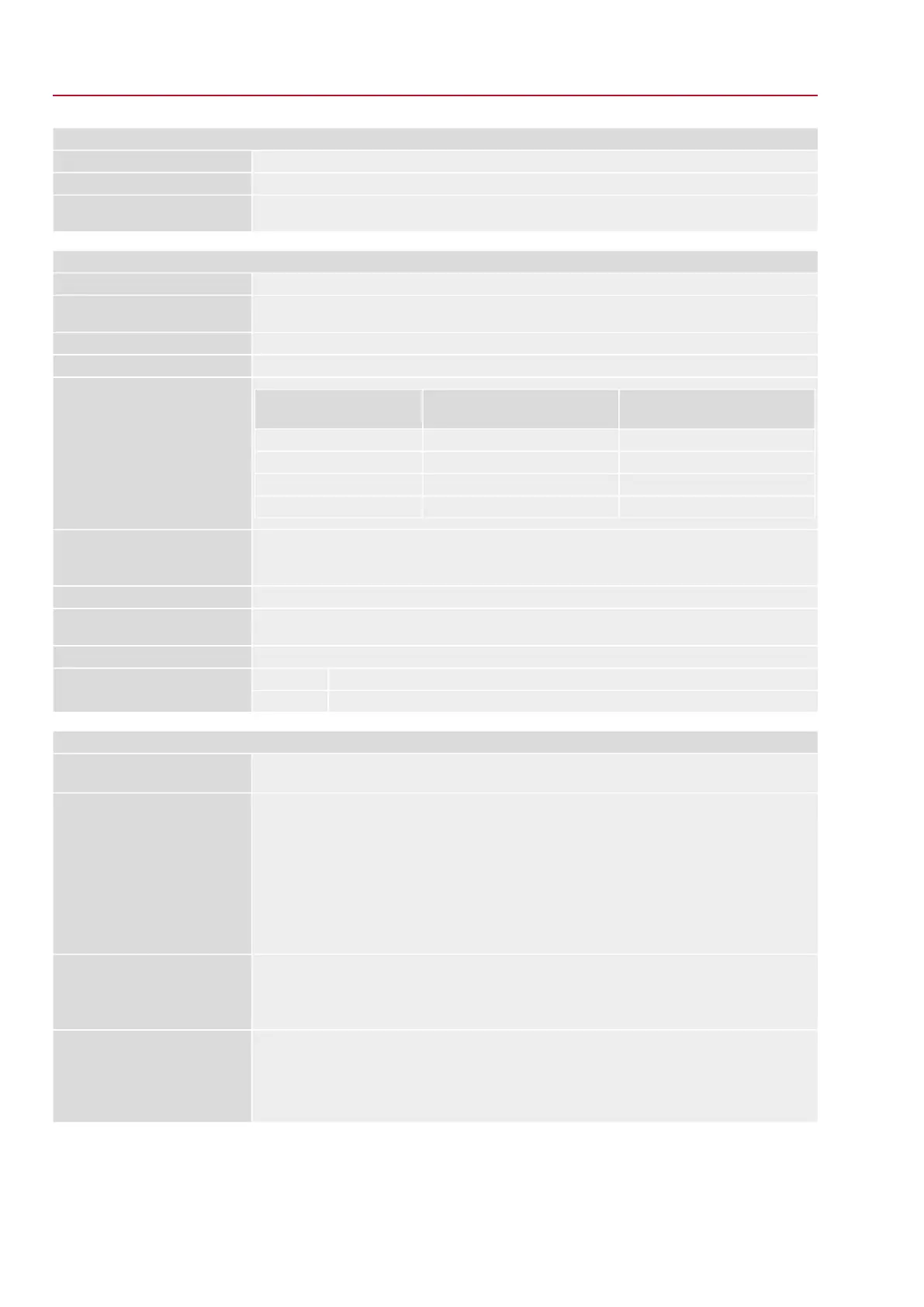

Commands and signals of the Profibus DP interface

OPEN, STOP, CLOSE, position setpoint, RESET, EMERGENCY operation command, enable local

controls, Interlock OPEN/CLOSE

Process representation output

(command signals)

●

End positions OPEN, CLOSED

●

Actual position value

●

Actual torque value, requires MWG in actuator

●

Selector switch in position LOCAL/REMOTE

●

Running indication (directional)

●

Torque switches OPEN, CLOSED

●

Limit switches OPEN, CLOSED

●

Manual operation by handwheel or via local controls

●

Analogue (2) and digital (4) customer inputs

Process representation input

(feedback signals)

●

Motor protection tripped

●

Torque switch tripped in mid-travel

●

One phase missing

●

Failure of analogue customer inputs

Process representation input

(fault signals)

The behaviour of the actuator is programmable:

●

Stop in current position

●

Travel to end position OPEN or CLOSED

●

Travel to any intermediate position

●

Execute last received operation command

Behaviour on loss of communication

96

SQEx 05.2 – SQEx 14.2/SQREx 05.2 – SQREx 14.2 Control unit: electronic (MWG)

Technical data ACExC 01.2 Non-Intrusive Profibus DP

Loading...

Loading...