20

CH 200 / CH 250

Operating

the machine

Lifting Capacity

Machine stability is maintained only when the forklift handles loads within its rated lifting capacity

and the various conditions listed above. The lifting capacity of the machine is determined by the

safe height and weight limits of the load. An overload on the forks makes the forklift unstable,

hard to handle, and will present the danger of tipping oven

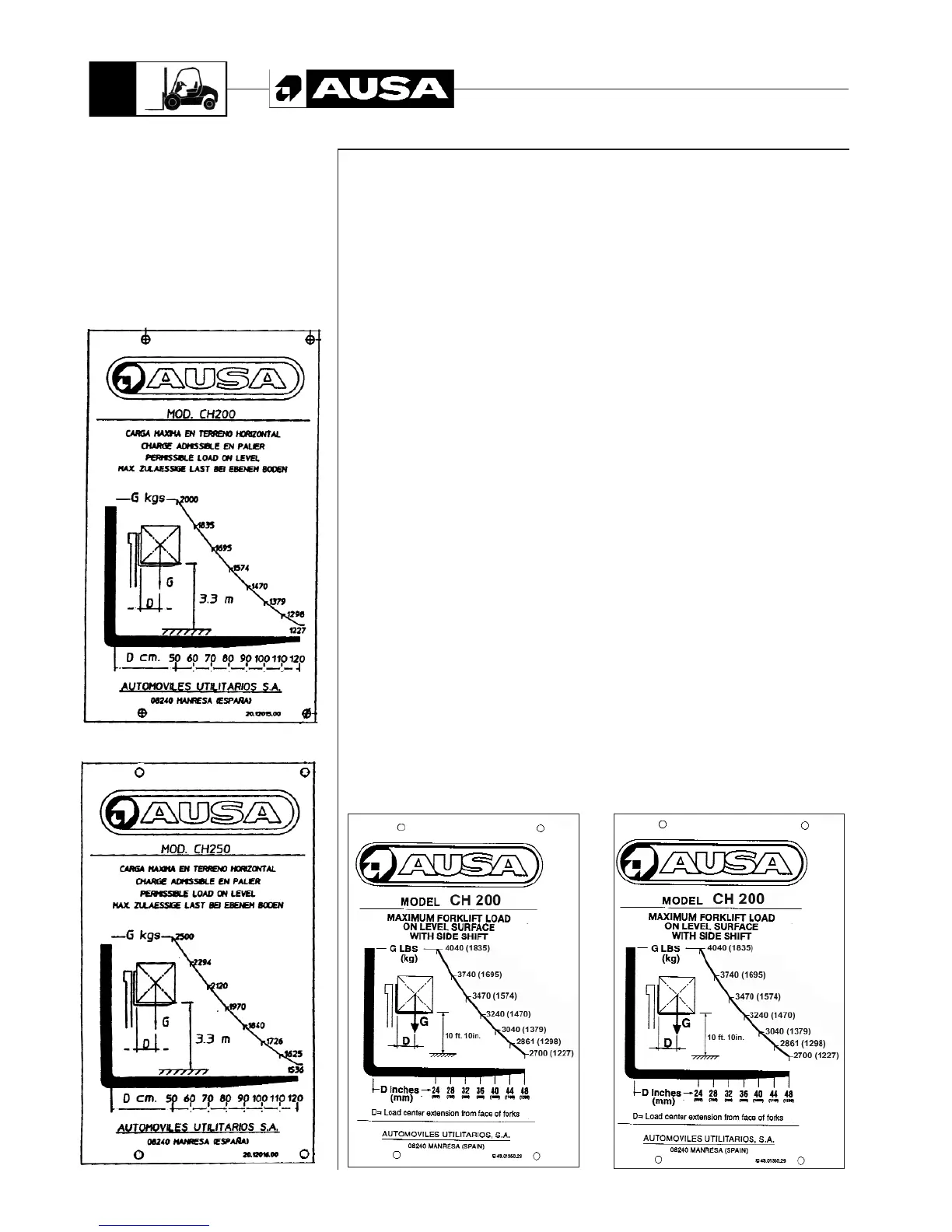

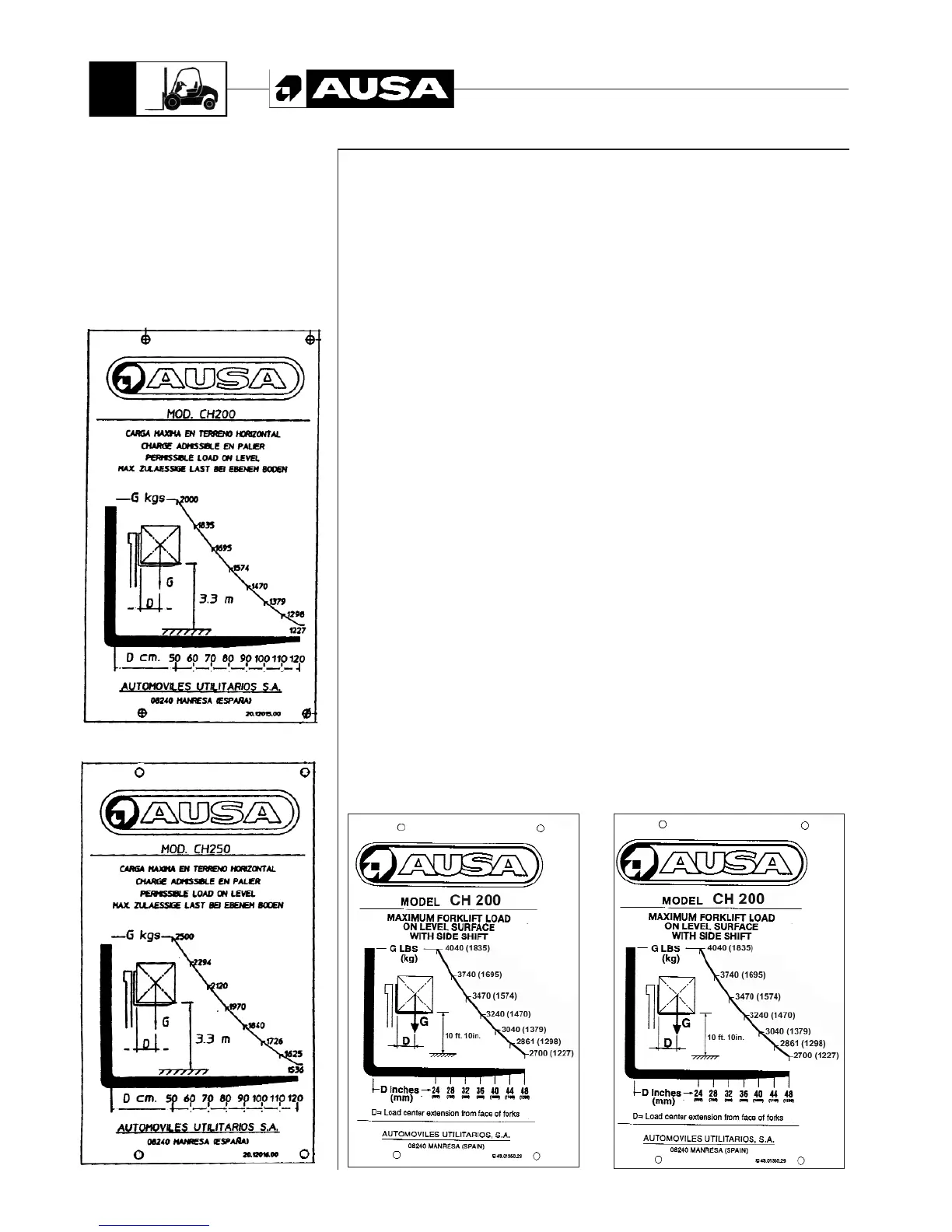

Load charts

The charts you can see in (figs. 1-2) shows how much your forklift can lift as the load centre incre-

ases out to 4 in. (100 mm). Note how the lift capacity decreases as the load centre increases.

This chart is reproduced as a machine decal and is located on the mudguard in front of the dri-

ver seat for ease of reference during machine operation (fig. 3).

The chart represents the load that can be lifted on a level surface, with the load evenly displaced

(like a square box with the weight centred), and a lift height (standard mast) of 10ft. 10in. (3,3 m.)

The horizontal axis “T" (often referred to as the X axis), represents the distance in inches (mm)

that the load centre is moved forward from the face of the forks.

The vertical axis "G" (often referred to as the Y axis), shows the load weight in pounds (kgs).

The raising and lowering of the load

Must be done with the mast in its vertical or tilted-back position. Using the machine with a raised

load tilted forward should only be done when unloading. The mast inclination is a useful feature

when handling a load, but it affects both lateral and longitudinal stability. It is recommended that

when operating with a high positioned load, you do not tilt the mast past the vertical position

more than strictly necessary.

The forklift is liable to roll forward when carrying a high positioned load with the mast forward of

the vertical point, if accelerating or braking abruptly.

(fig. 1) - U.K.

(fig. 2) - U..K.

(fig. 1) - U.S..A

(fig. 1) - U.S.A

Loading...

Loading...