22

GLASS CLEANING

The best way to clean the combustion

chamber doors is using a damp cloth.

Stubborn dirt can be removed using the

RIKA glass cleaner (obtainable from your

specialist fire dealer).

mon

thly!

FLUE GAS OUTLETS

(if used frequently)

Remove the upper and lower flue plate for

the rear wall and vacuum the flue ash that

has collected there out of the flue gas out-

lets that are now laid bare.

mon

thly!

FLUE GAS BOX

Clean the flue gas box that sits behind the

heat exchangers in the same way. To do this

the right hand rear cladding is removed and

the cleaning lid (see Fig. 3, Part 8) unscre-

wed.

If the outlet openings are blocked, then

these must be freed and vacuumed (if

required).

ASHTRAY

Empty the ashtray as required. It must only

be removed from the fire, when the fire is

switched off and cooled down.

WOOD ASH AS A FERTLISER

Wood mineral percentages (approx. 1 - 2%)

remain as combustion remains as ash in the

combustion chamber. This ash is natural

product and is an excellent fertiliser for all

plants in the garden. However the ash

should be aged first and “quenched” with

water.

Please TAKE CARE: Embers can be hidden in

the ash - only fill into metal containers.

Vacuuming using the RIKA ashbox is

recommended to remove the ash.

24

MAINTENANCE AND CLEANING Con’t

ash pan is

local dealer).

.

Empty the ashtray as required. It must

only be removed when the stove is

switched off and cooled down.

Please TAKE CARE: Remove

embers into metal containers, ONLY

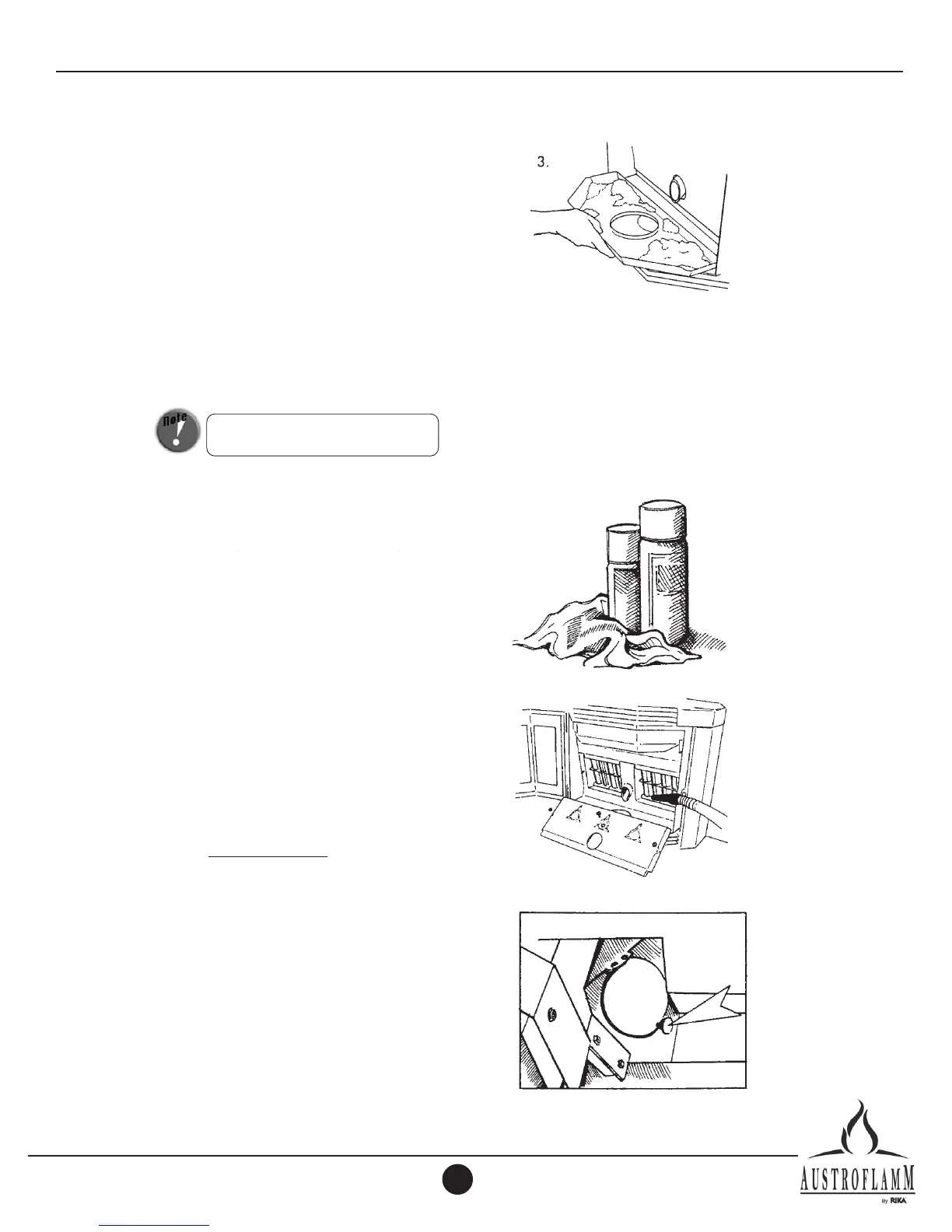

HEAT EXCHANGER OUTLETS

cast walls in

of the firebox as shown.

Hex head tool provided.

Vacuum the area thoroughly.

Rear Ash Chamber

Remove the rear ash trap door located

behind the right side rear panel. Vacuum

the chamber that extends across to the

combustion motor housing. Pay close

attention to the pass through holes coming

from the front of the heat exchanger area and

make sure they are clean and clear from any

obstruction. If these holes are blocked the

unit will not operate properly and might not

run at all. This should be checked for every 1

ton of fuel to see if the cleaning intervals

might be increased or decreased. Fuel

quality and extended low burn rates will

increase the frequency required.

The best way to clean the glass is using a

damp cloth or stubborn dirt can be removed

using the glass cleaner (obtainable from

your local dealer).

Loading...

Loading...