H-85

(A)

Photo

electric

sensor

(B)

Fiber

optic

sensor

(C)

Door/Area

sensor

(D)

Proximity

sensor

(E)

Pressure

sensor

(F)

Rotary

encoder

(G)

Connector/

Socket

(H)

Temp.

controller

(I)

SSR/

Power

controller

(J)

Counter

(K)

Timer

(L)

Panel

meter

(M)

Tacho/

Speed/ Pulse

meter

(N)

Display

unit

(O)

Sensor

controller

(P)

Switching

mode power

supply

(Q)

Stepper

motor&

Driver&Controller

(R)

Graphic/

Logic

panel

(S)

Field

network

device

(T)

Software

(U)

Other

Dual PID Auto Tuning Control

Equipment

to be

controlled

Converter

Analog output

1-5VDC

0-10VDC

DC4-20

mA

TZ

Series

SSR

Load

power

Power

Voltage

output

terminal

+

-

I

N

P

U

T

L

O

A

D

T

TZ

Series

DC4-20

mA

LOAD 600Ω Max.

Power controller

Load

power

Load

Current

output

terminal

U

W

R

+

-

TZ

Series

Recording instrument

/Panel meter

DC4-20

mA

IN

Tranmission

output

terminal

+ +

- -

RS485

PC

RxD

RxD

TxD TxD

Gnd

Gnd

IN

TZ/TZN

Series

Converter

Communi

cation

output

terminal

+

-

TZ

Series

Relay contact terminal

Heater

Power

L

C

H

Magnet or

Relay contact

Condenser

0.1

㎌

630V

A

Input correction [

IN-B

]

Input correction is to correct deviation occurred from

temperature sensor such as thermocouples, RTD, Analog

sensor etc. If you check the deviation of every temperature

sensor precisely, it can measure temperature accurately.

● Input revise can be set at

IN-B

mode in parameter 1

group.

● Use this mode after measuring deviation occurred

from temperature sensor exactly. Because if measured

deviation value is not corrected, dis-played temperature

may be too high or too low.

● Set range: -49 to 50

℃

(-50.0 to 50.0

℃

)

● When you set the Input revise value, you may need

to record it, because it will be useful when performing

maintenance.

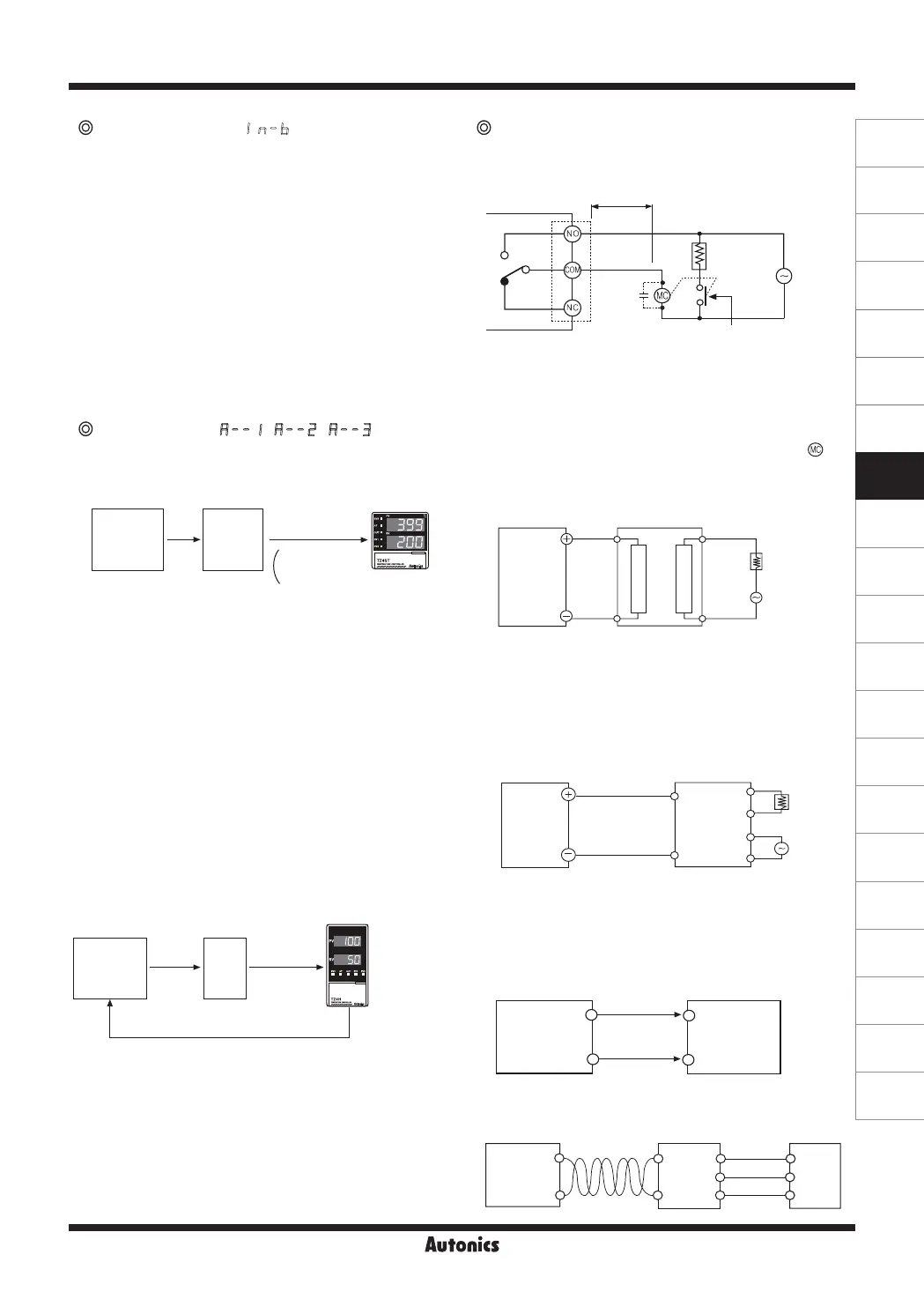

Analog input [

A--1

,

A--2

,

A--3

]

● In case of measuring or controlling humidity & pressure,

flux, etc, it uses the proper converter which is converting

the measuring value to DC4-20mA or 1-5VDC or 0-10VDC.

● To use analog output of converter as controller input,

select the input type as same as analog output

conditions. (This should be operated in power-off status.)

● This unit has the mode for the converter built-in.

● Please select

A--1

(0-10VDC) or

A--2

(1-5VDC)

or

A--3

(DC4-20

mA

) in selection mode of input in parameter 2 group.

● Set the input value by High scale

[

H-SC

]

and Low scale

[

L-SC

]

mode.

● Please connect the analog output of the converte to the

temperature sensor terminal of the controller. Please be

cautious of the polarity.

● After the procedure, it is controlled same with temperature

control.

● Example of usage

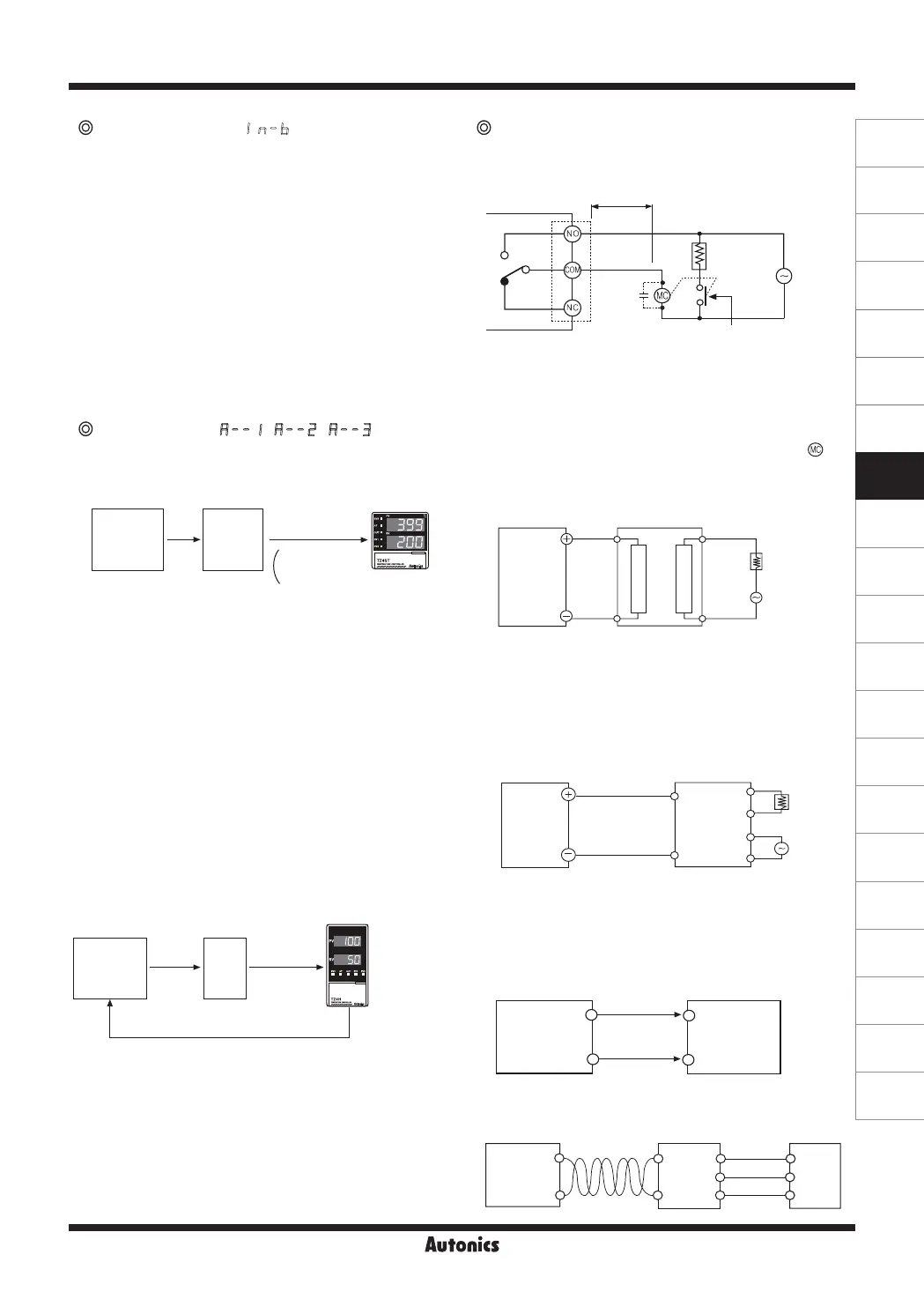

Output connections

●

Application of relay output type

Keep power relay as far away as possible from TZ/TZN

Series

. If wires length of A is short, electromotive force

occurred from a coil of magnet switch & power relay may

flow in power line of the unit, it may cause malfunction.

If wires length of A is short, please connect a mylar

condenser 104(630V) across coil of the power relay "

" to

protect electromotive force.

●

Application of SSR output type

※

SSR should be selected by the capacity of load,

otherwise, it may short-circuit and result in a fire. Indirect

heated should be used with SSR for efficient working.

※

Please use a cooling plate or it may cause the capability

deterioration, breakdown of SSR for a long usage.

●

Application of current output(DC4-20mA)

※

It is important to select SCR unit after checking the capacity

of the load.

※

If the capacity is exceeded, it may cause a fire.

●

Application of communication output(RS485)

●

Application of transmission output(DC4-20mA)

For more information about output, refer to the H-139 page.

Pressure

sensor

Pressure

Temperature

controller

Feedback

IN-T

setting

:

A--3

H-SC

setting

:

100

L-SC

setting

:

0

DC4-20mA

Converter

Control

system

(0 to 100kg)

Loading...

Loading...