What to do if the Azbil Control Unit valve operation is sluggish or inoperative?

- Ssophia77Aug 10, 2025

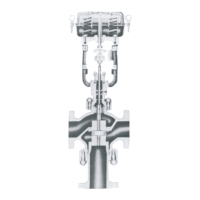

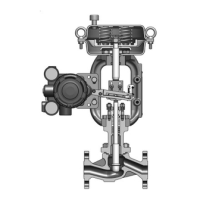

Sluggish or inoperative valve operation in your Azbil Control Unit can arise from a few common issues. First, inspect the piping and actuator for any air leaks. If found, address these leaks promptly. Additionally, check for any foreign matter that may be lodged in the guide section of the valve plug and remove it. If the gland packing is aged and hardened, causing increased hysteresis, it should be replaced. Lastly, a malfunctioning positioner can also cause these symptoms; test the positioner by operating it directly on a known, normally operating air supply.