What to do if my Azbil AGVB valve is not operating?

- MMaria BellAug 14, 2025

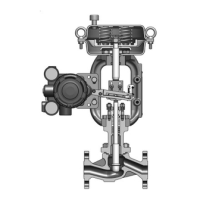

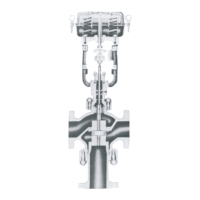

If your Azbil Control Unit valve isn't operating, several issues could be the cause. Start by checking for leaks in the signal pipe or air pipe, especially at the fittings. Also, examine the diaphragm for any damage and consider replacing it if necessary. Ensure the air pressure regulator filter isn't clogged and that the controller, positioner, and pilot valve are functioning correctly. If those aren't the problem, disassemble and inspect the valve body for obstructions or damage to the valve stem or plug, addressing any issues found.