Additional specifications

•

Material certificate (mill test report)

• Radiographic testing

• Liquid penetrant inspection

• Flow characteristic inspection

• Degreasing and moisture removal

• Copper-free treatment (fluid contact part)

• SUS304 for bolts and nuts exposed to the air

• Salt-resistant coating

• Cold-area use specifications

• Tropical-area use specifications

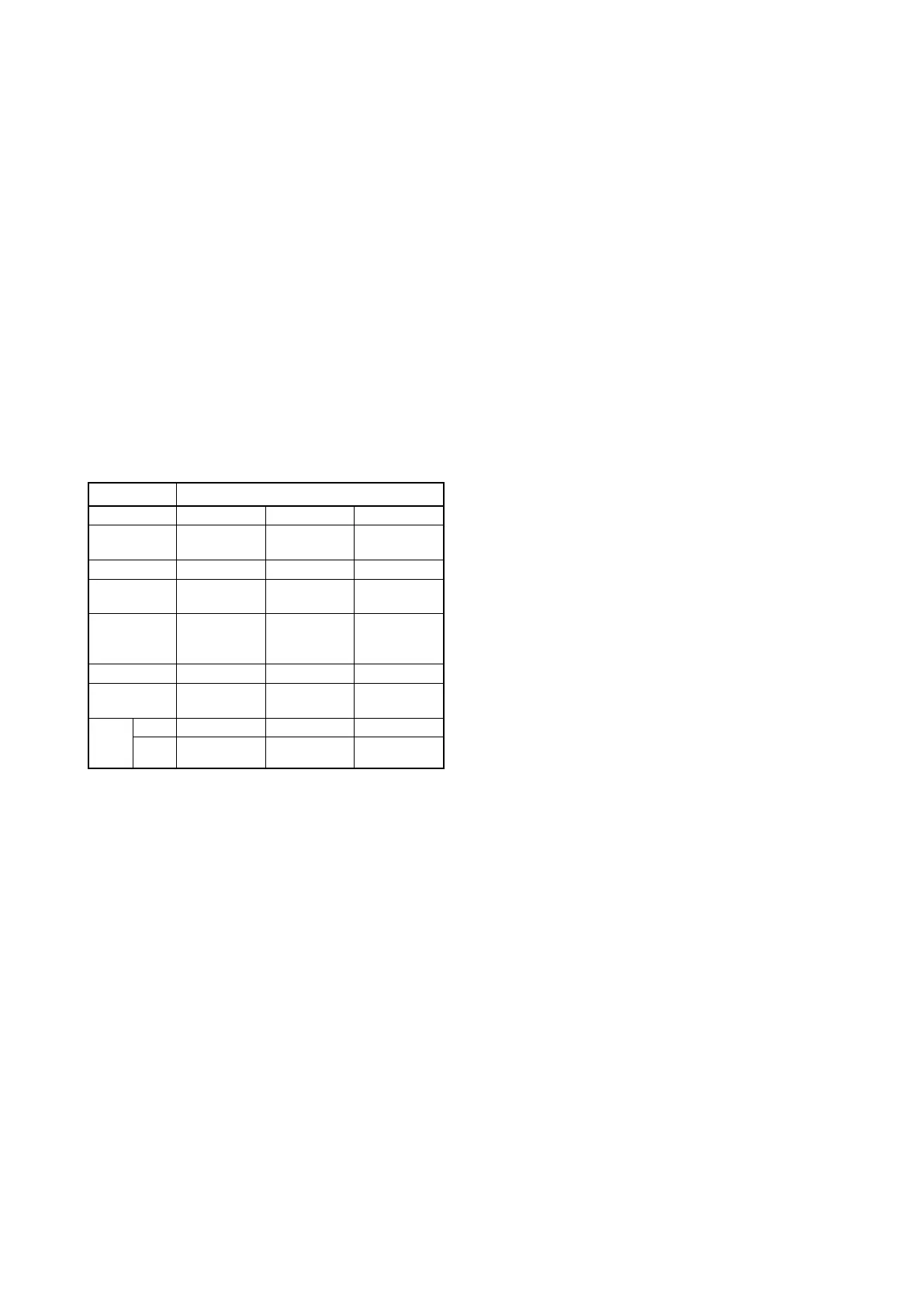

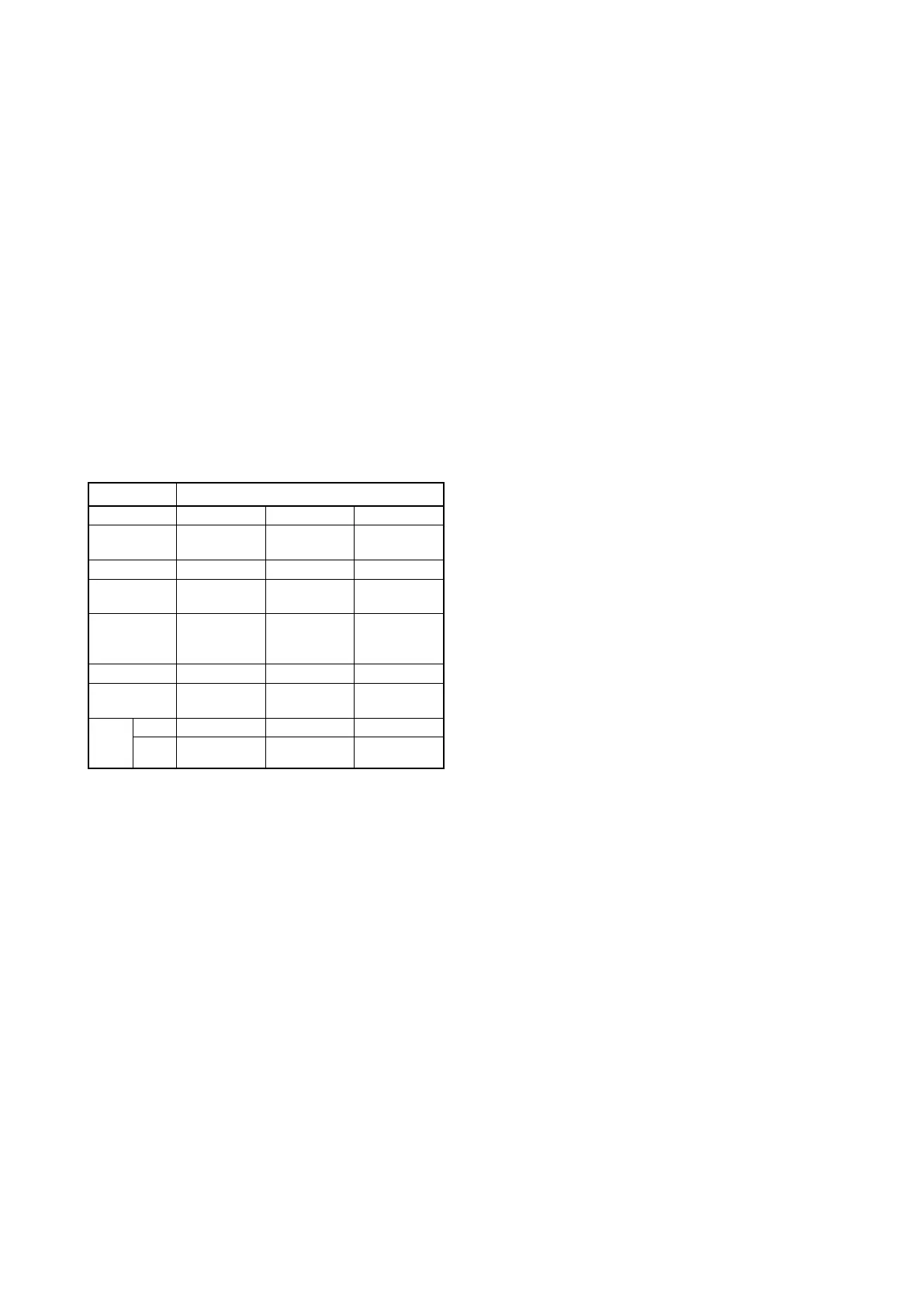

Table A-1. Materials of the body, plug, and seat ring

Trim material Operating temperature (°C)

SUS316 -5 to +300 -45 to +300 -45 to +300

SUS316

CoCr-A

-5 to +400 -196 to +400 -196 to +400

SUS440C -5 to +400 -45 to +400 –

SUS316,

soft seat

-5 to +230 -45 to +230 -45 to +230

SUS316,

CoCr-A

surface

-5 to +400 -196 to +400 -196 to +400

SUS316L – -45 to +300 -45 to +300

SUS316L

CoCr-A

– -196 to +400 -196 to +400

Body

mate-

rial

JIS SCPH2 SCS13A SCS14A

ASTM A216WCB A351CF8 A351CF8M

Note: The set of parts for adjusting the flow (plug, seat ring,

etc.) is referred to as the trim.

A-2

Loading...

Loading...