Chapter 3. Operation

3-1. Trial-Run Inspection and Adjustment

(1) Operation test

Send a 4–20 mA DC or other dummy signal (0 to 100 %) to the valve positioner or

actuator to check that the rated travel is achieved.

Refer to

Table 3-1 and if the allowable value is exceeded, adjust the valve positioner.

For adjustment of the valve positioner, refer to the related user’s manual indicated in

“Chapter 1. Structure of the Control System”.

Table 3-1. Control valve performance (when shipped from factory)

Positioner Hysteresis Linearity

AVP, HTP Within 1 % FS Within ±1 % FS

VPE Within 1 % FS Within ±3 % FS

(2) Loop check

Send signals from the host control system, and check that signal wires are connected as

specified and that the functional requirements for control are satisfied.

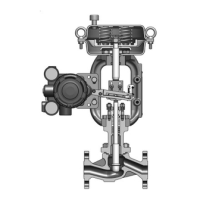

3-2. Use of the Side Handwheel

This section describes opening and closing the control valve with the side handwheel. If

you need to use the side handwheel, refer to this section. Figure 6-15 illustrates the side

handwheel structure.

Precautions

If the handwheel is used when the equipment is running, make sure that manual opening/

closing of the control valve does not affect the operation of the equipment.

Procedure

Step Procedure

1 Remove the handle lock from the handwheel.

2 Check the OPEN and SHUT arrows cast on the handwheel, and rotate the handwheel in

the desired direction to open or close the valve. The maximum turning torque:

PSA1, PSA2: 190 N

PSA3, PSA4: 450 N

3 When the handwheel does not turn any further, stop trying to turn it and check the

amount of valve travel.

CAUTION

Do not apply excessive force when the mechanical stop posi-

tion of the control valve has been reached. Otherwise you may

damage the valve stem. If the valve stops at an abnormal posi-

tion, refer to “3-3. Troubleshooting” and take the necessary

countermeasures.

4 To resume automatic operation, turn the handwheel until the pointer on the side

handwheel main unit reaches the AUTO position. Lock the handwheel, and resume

automatic operation.

3-1

Loading...

Loading...