8-3. Assembling the Parts of the Gland

8-3-1. Preparation for Assembly

(1) Checking the surface condition of the parts

Any flaw or the like on the surface of the parts may cause leakage from that area, and

the specified seal performance may not be achieved. Therefore, check the surface of the

following parts.

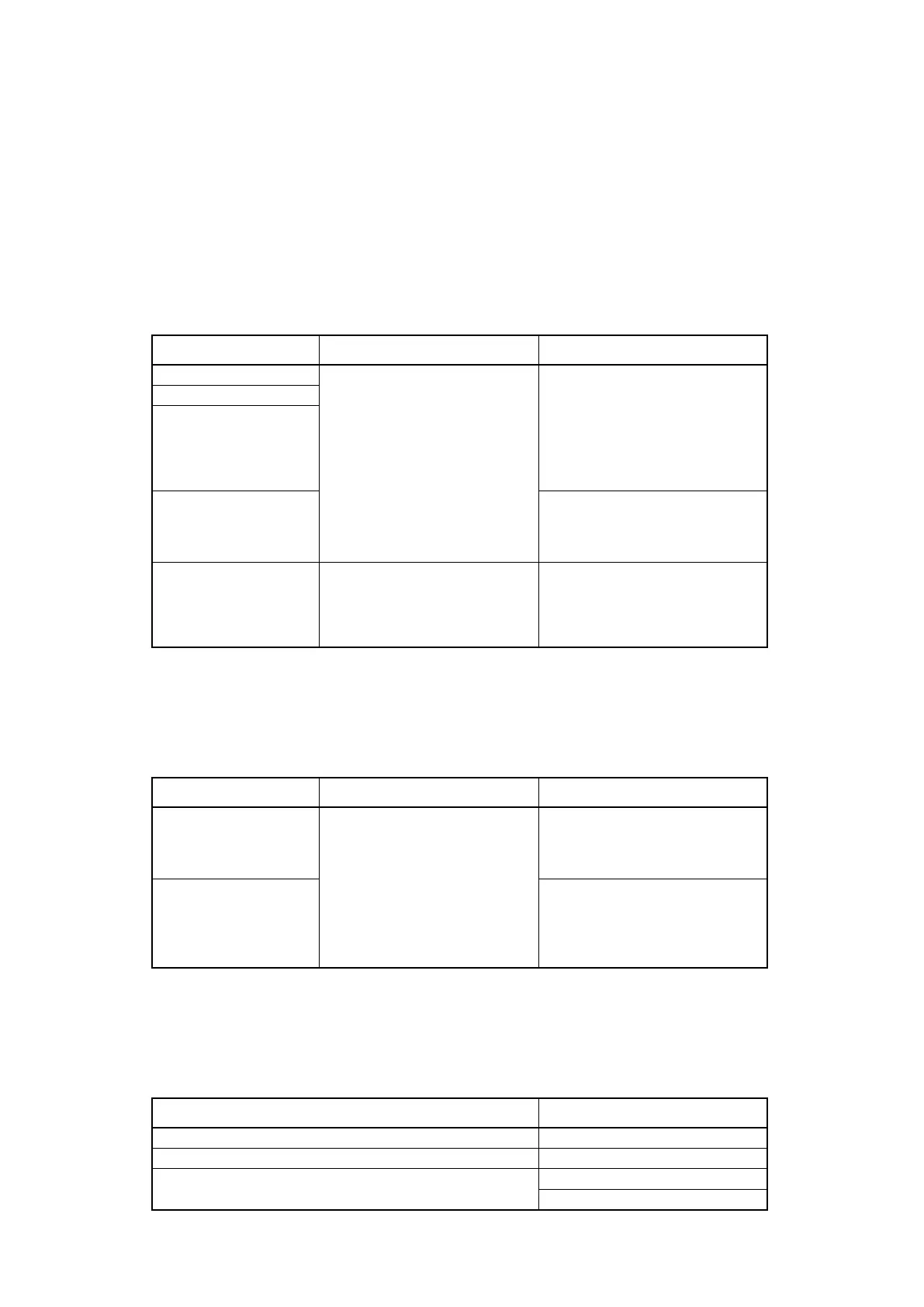

Table 8-1. Parts to be checked for surface condition

Part name Checkpoints Possible problems

Stem

•

No flaws or defects, including

scratches and dents

•

No rust or corrosion

•

The entire surface is even.

•

No burrs

•

Clean surface, with no adhering

coating material, powder, or dirt.

•

If necessary, take necessary

measures such as cleaning with

alcohol.

Any flaw, rust, corrosion, burrs, dirt,

etc., may cause leakage from that

area, and the specified seal perfor-

mance may not be achieved.

Stuffing box

Both ends of the spacer

Packing follower

Packing contact surface

O-ring groove

Packing flange

Gland nut contact surface

Any flaw, rust, corrosion, burrs, dirt,

etc., may cause insufficient tighten-

ing, and the specified seal perfor-

mance may not be achieved.

Packing flange

Entire surface

Gland stud bolt

Gland nut

•

No flaws, rust, or defects Any flaw, rust, defect, etc., may cause

control valve damage, leading to

injuries.

(2) New parts

When assembling or reassembling, for the parts indicated in the table below, be sure to use

new parts.

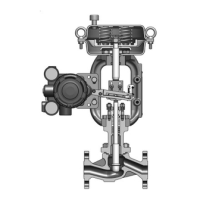

Table 8-2. Parts requiring replacement

Part name Checkpoints Possible problems

Gland packing No flaws. No coating materials or

dirt stuck to the surface.

Any flaw, coating material, dirt, etc.,

may cause leakage from that area,

and the specified seal performance

may not be achieved.

Belleville spring Any flaw, coating material, dirt, etc.,

may cause insufficient tightening

and leakage from the gland in a short

period of time, and the specified seal

performance may not be achieved.

(3) Lubricating grease and anti-seizing agent

Have an appropriate amount of the following lubricating grease and anti-seizing agent (or

equivalent) on hand.

Table 8-3. Lubricating grease and anti-seizing agent

Product name Applied area

G40M silicone grease, made by Shin-Etsu Chemical Co., Ltd. Entire surface of the gland packing

Plastilube No. 3 non-dripping grease, made by Sulflo Inc. Entire surface of the backup O-rings

Never-Seez anti-seizing agent, made by Bostik Inc. Threads of the gland stud bolts

Bottom of the gland nuts

8-2

Loading...

Loading...