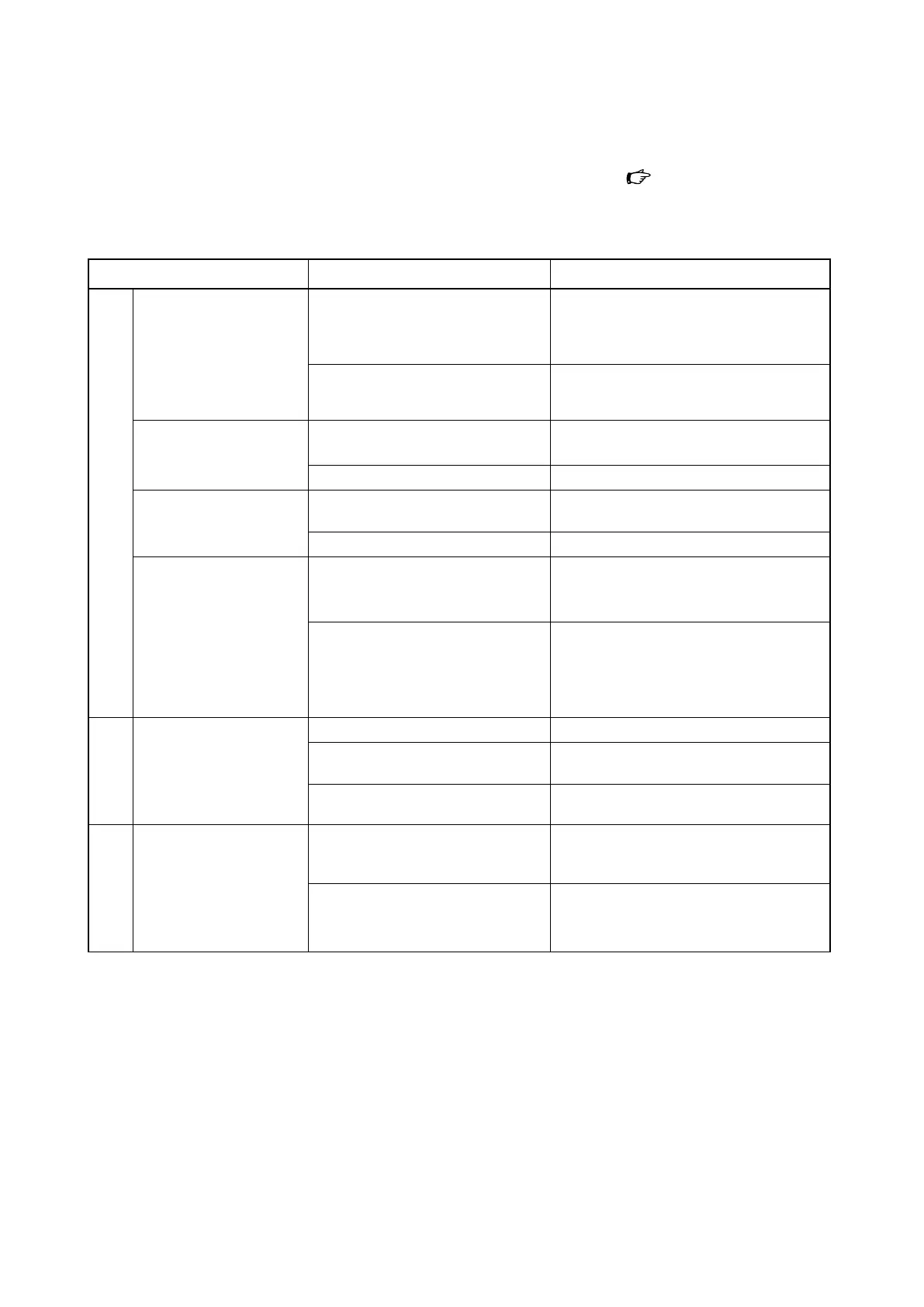

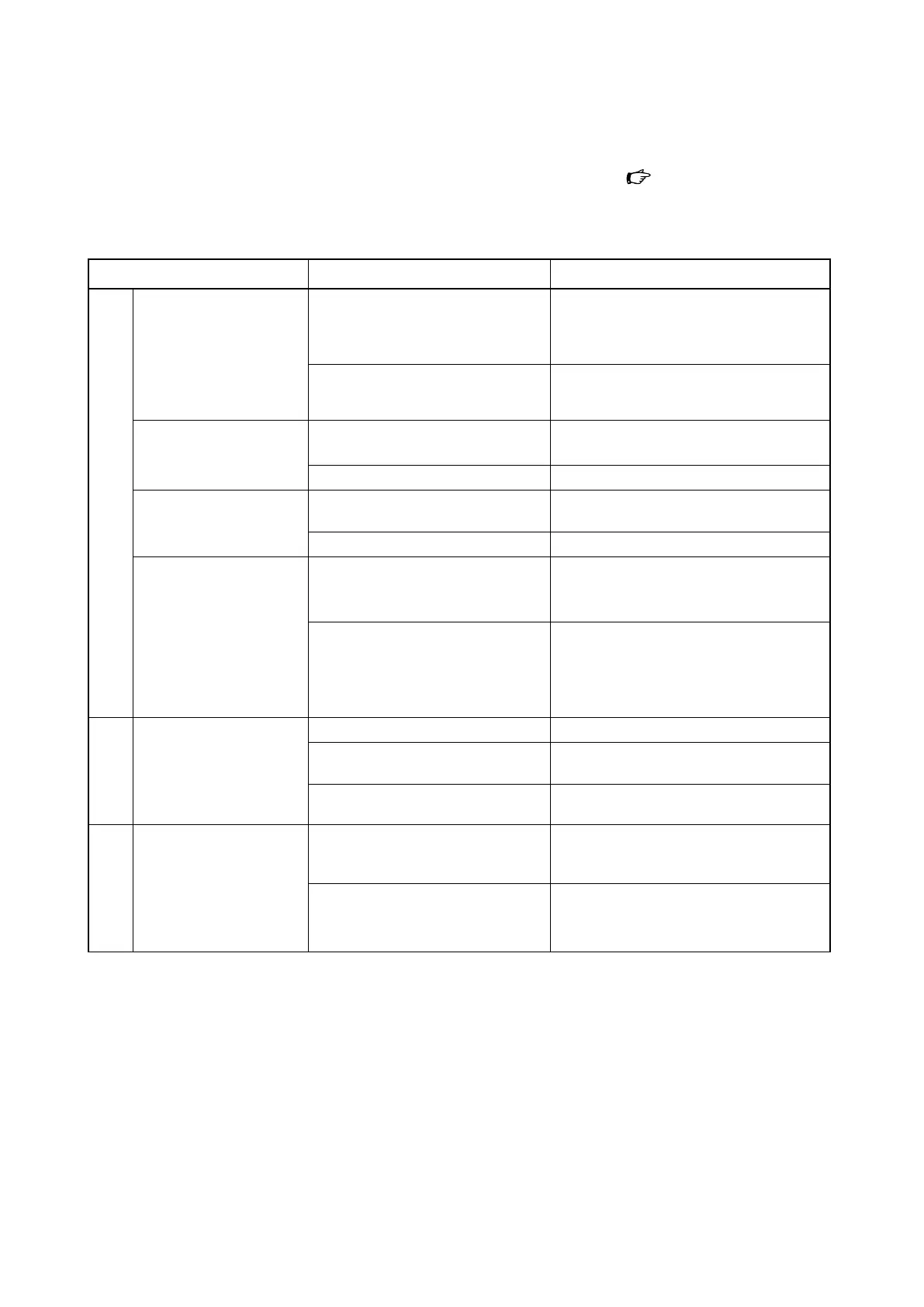

3-3. Troubleshooting

Problems that might occur during operation are described in Table 3-2.

Take necessary measures such as replacing parts, depending on the circumstances

Table 3-2. Control valve problem causes and countermeasures

Phenomenon Cause Countermeasure

Unreliable valve operation

The valve hunts near the

fully closed position.

The valve capacity is too large.

•

Reduce the differential pressure between the

inlet and outlet of the valve.

•

Replace the valve trim with trim that has a

smaller Cv.

Reverse flow direction

•

Check that the flow direction indicated on

the valve is the same as the fluid direction. If

not, change the direction.

Fluctuation in supply air

pressure

Insufficient instrumentation air capacity

of the equipment

•

Increase the capacity of the compressor.

•

Install an additional dedicated compressor.

Failure of the air pressure regulator

•

Check the air pressure regulator.

Hunting of signal pressure The resistance or air volume of the con-

trol loop is not suitable.

•

Insert an air volume tank or restrictor into

the signal pressure line.

Failure of the controller

•

Check the controller.

The valve hunts even

though signals and supply

air pressure are stable.

Hunting of the positioner circuit

•

Check for wear of the positioner

•

Check the positioner and pilot valve

•

Reduce the sensitivity of the positioner

Fluctuation in axial thrust due to

changes in fluid pressure in pipes

•

Reduce the differential pressure between the

inlet and outlet of the valve.

•

Replace the actuator with one that has more

rigidity.

•

Add a positioner.

Valve vibration

The valve vibrates at any

travel.

Insufficient support for the piping

•

Support the inlet and outlet of the valve.

There is a source of vibration around

the valve.

•

Remove the source of vibration.

The guide is worn out.

•

Replace the guide bushing and/or the valve

plug.

Slow valve stroke

Valve stroke is slow in

both opening and closing

directions.

The valve plug guide, the fluid retaining

part of the bonnet, etc., is clogged with

slurry.

•

Disassemble and clean.

•

Install a steam jacket on the valve body.

The gland packing is hardened.

•

Replace the gland packing or the grease.

3-2

Loading...

Loading...