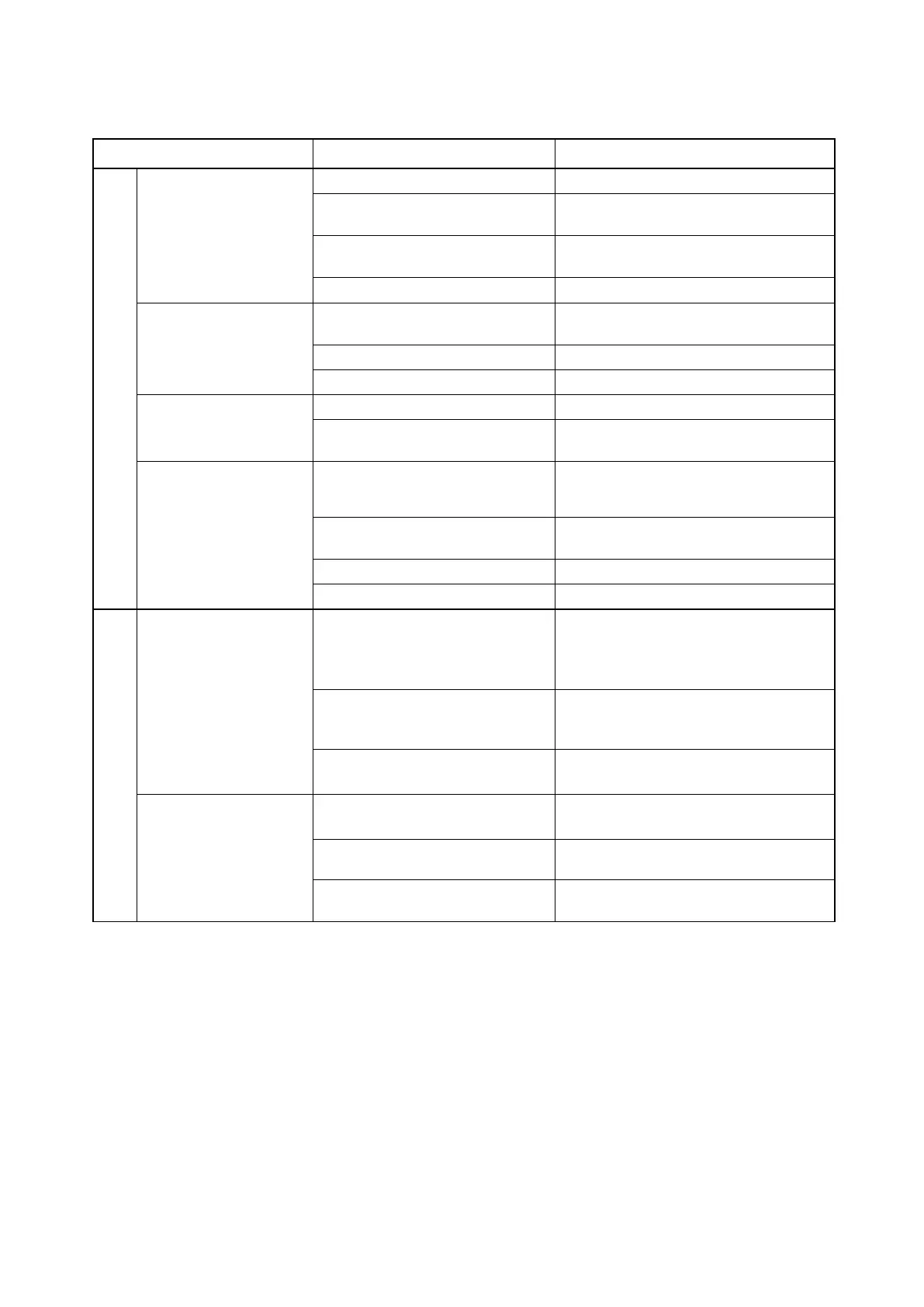

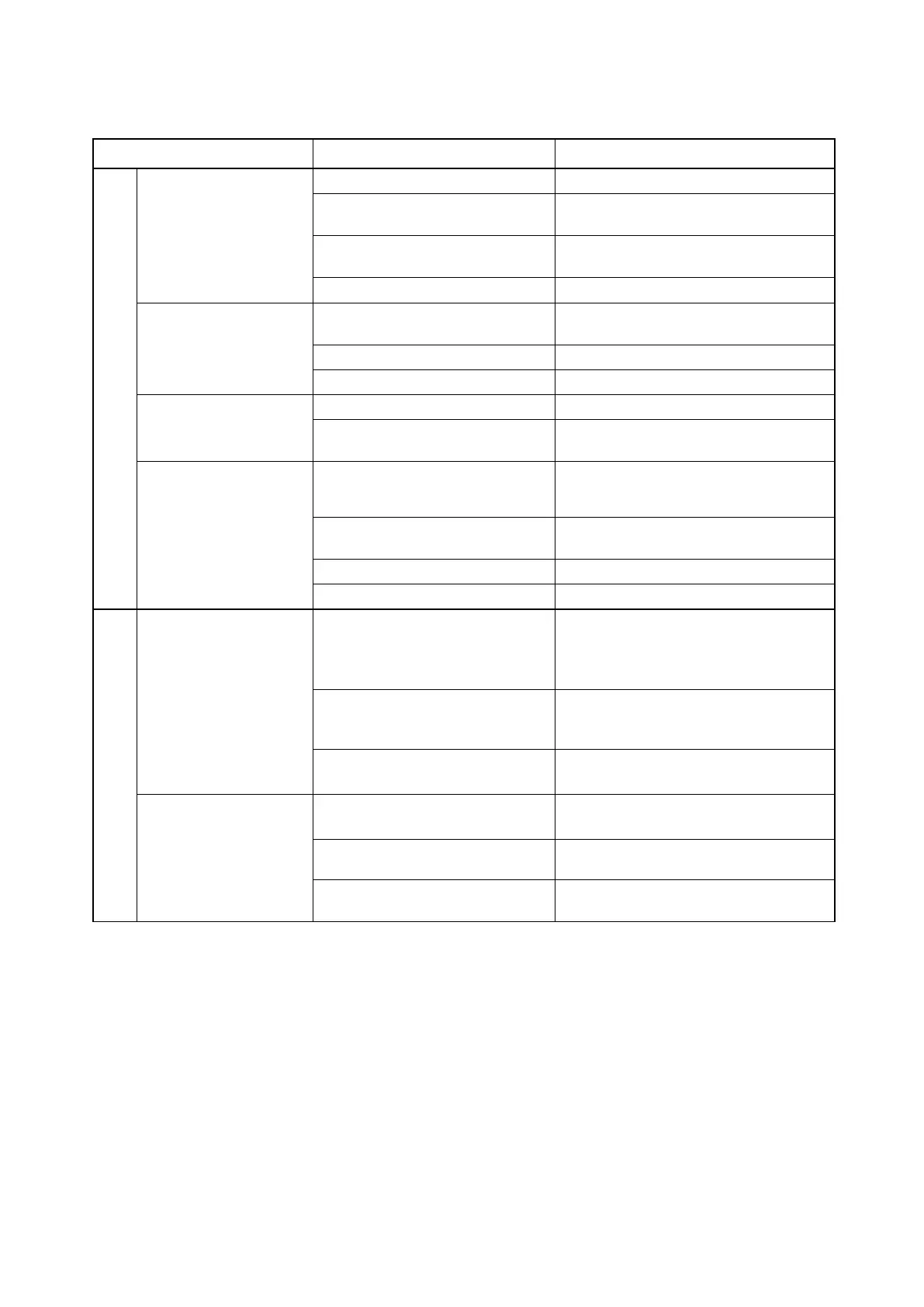

Table 3-2. Control valve problem causes and countermeasures

Phenomenon Cause Countermeasure

Valve not operating

Supply air pressure is

normal, but signal pressure

does not increase

Leakage from the signal pipe

•

Check the signal pipe (especially the fitting)

Leakage from the diaphragm or

damage to the diaphragm

•

Replace the diaphragm.

Leakage from the signal receiver of the

positioner or damage to it

•

Replace the bellows receiver and/or the

diaphragm

Failure of the controller

•

Check the controller.

Signal pressure is normal,

but supply air pressure

drops or air is not supplied

Clogging of the filter in the air pressure

regulator

•

Clean the filter.

Leakage or clogging of the air pipe

•

Check the air pipe (especially the fitting)

Failure of the air pressure regulator

•

Check the air pressure regulator.

No positioner output Failure of the positioner and pilot valve

•

Check the positioner and pilot valve.

Leakage from the actuator diaphragm

or damage to the diaphragm

•

Replace the diaphragm.

The valve does not operate

even though air is supplied

to the actuator

The valve stem, valve plug guide, etc., is

stuck due to heat or foreign matter.

•

Disassemble and inspect the valve body, and

reprocess or replace the valve stem or guide

bushing with new ones.

Foreign matter is caught in the valve

plug.

•

Disassemble, inspect, and clean the valve

body.

The valve stem is bent.

•

Repair the valve stem.

Actuator failure

•

Check the operation of the actuator.

Valve does not fully open /

leakage from the valve interior in large amounts

The valve stem is at the

valve fully-open position.

The valve plug and/or the seat ring is

corroded, eroded, abraded, or other-

wise damaged.

•

Lap the valve plug and seat

•

Re-machine the valve plug and seat.

•

Replace the valve plug or/and the seat ring

(consider using hardened parts)

Parts on the outer circumference of the

seat ring (thread or gasket) are corroded

or eroded.

•

Replace the seat ring or the gasket.

•

Use a different mounting method for the

seat ring (e.g., welding).

The fluid leaks from the partition of the

valve body.

•

Weld pinholes.

•

Replace the valve body.

The valve stem does not

reach the fully closed

position.

The differential pressure of the fluid is

too great.

•

Reduce the differential pressure.

•

Increase the output from the actuator.

Foreign matter is caught in

•

Disassemble, inspect, and clean the valve

body.

The valve stem, valve plug guide, etc., is

stuck due to heat

•

Separate these parts.

3-3

Loading...

Loading...