2-2. Check before Installation on the Pipe

Check the following before installing the AGVB control valve on the piping.

1. The specifications printed on the name plate are

appropriate for the use.

2. There is no damage to the valve (including the actuator and

auxiliary equipment).

3. There is no damage to the flanges on the piping.

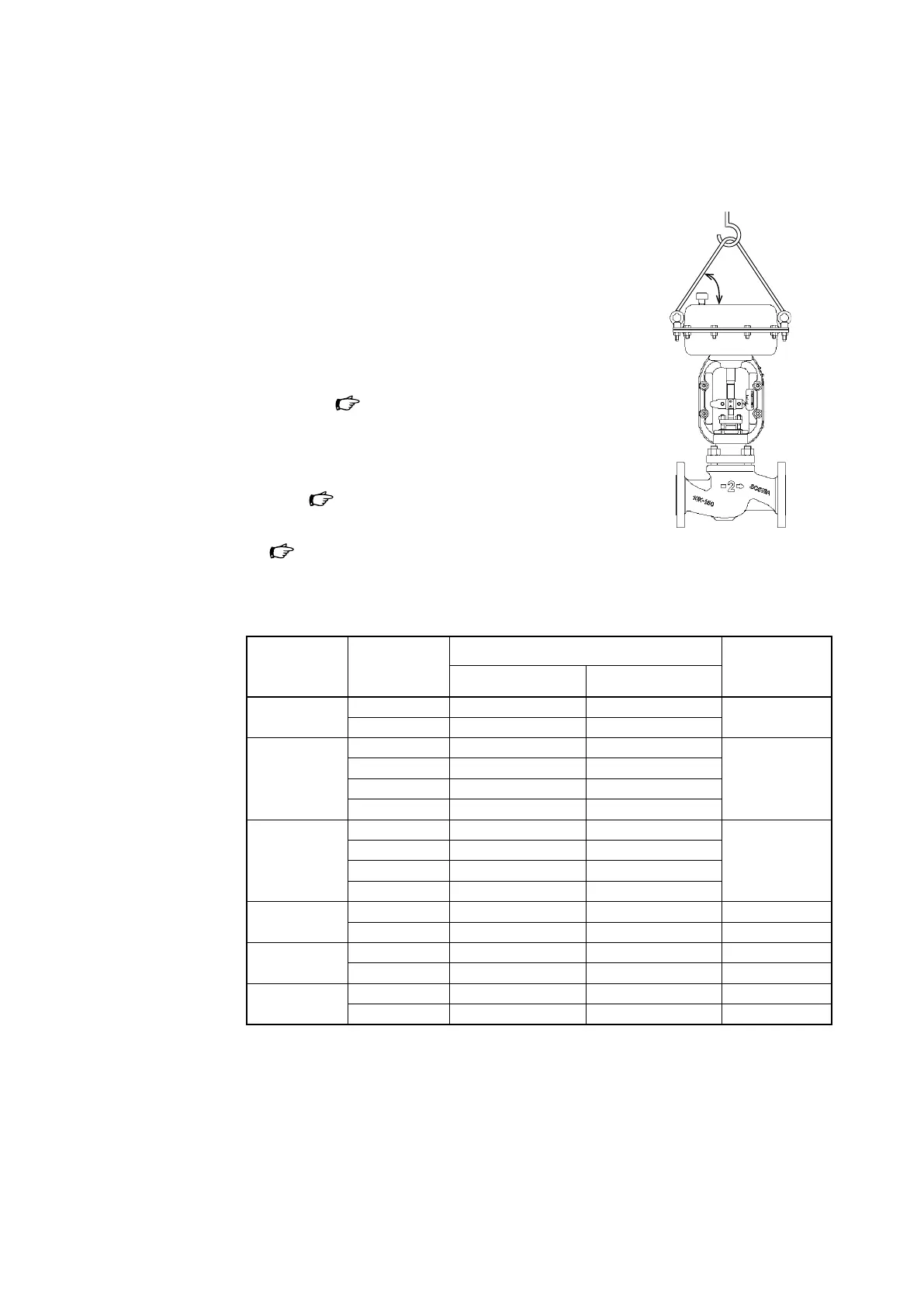

4. Eyebolts for hoisting are attached to the actuator. If the

eyebolts are used to hoist the control valve, make sure that

the weight including accessories does not exceed the limit

specified in

“Table 2-1. Max. weight for hoisting with

e y e b o l t s”.

5. If the eyebolts are used to hoist the control valve, the angle

between the actuator and the wire rope must be 60° or

more. (

Figure 2-1).

6. The piping can support the weight of the control valve

(

Table 2-1).

60°

Figure 2-1. Example of hoisting

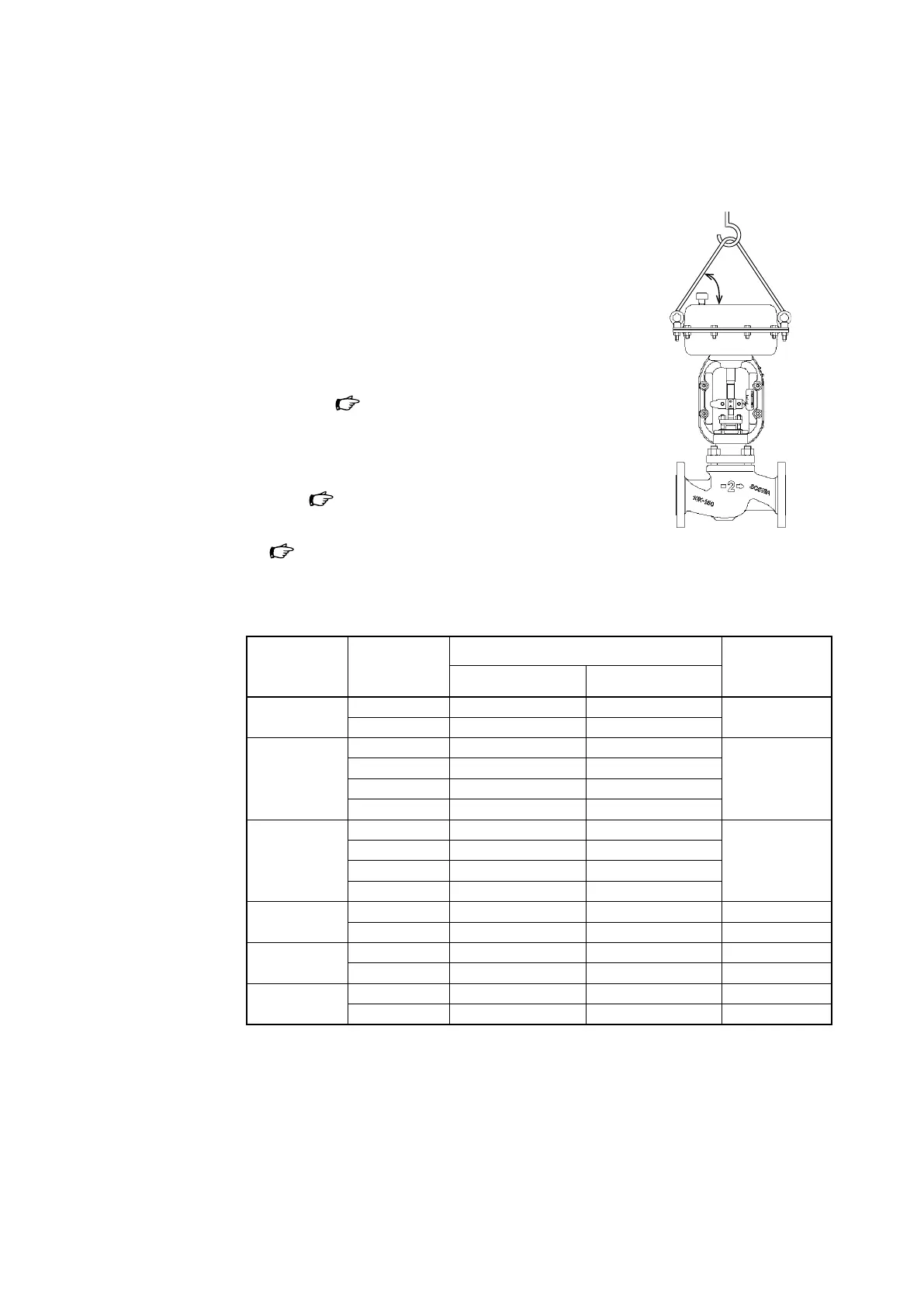

Table 2-1. Max. weight for hoisting with eyebolts

Unit: kg

Connection

diameter

(inches)

Actuator Product weight (standard bonnet) Max. weight for

hoisting with

eyebolts

Without handwheel With side handwheel

1/2, 3/4, 1 PSA1D, R 17 24 160

PSA2D, R 18 25

1-1/2 PSA1D, R 25 32 160

PSA2D, R 26 33

PSA3D, R 43 44

PSA4D, R 55 56

2 PSA1D, R 26 33 160

PSA2D, R 27 34

PSA3D, R 43 44

PSA4D, R 55 56

2-1/2 PSA3D, R 58 82 160

PSA4D, R 70 100 440

3 PSA3D, R 62 86 160

PSA4D, R 74 104 440

4 PSA3D, R 67 91 160

PSA4D, R 79 109 440

2-4

Loading...

Loading...