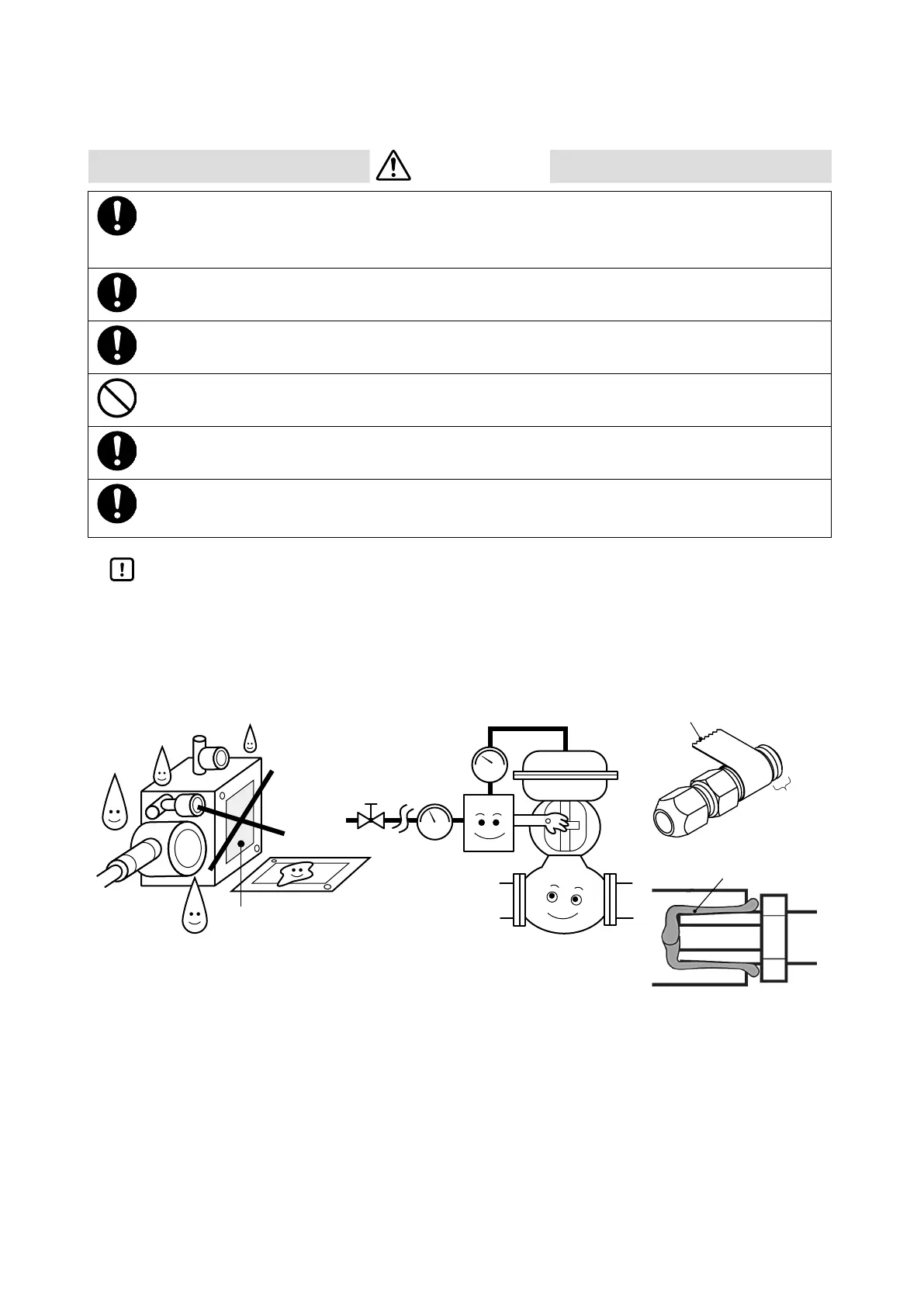

Precautions for Air Supply Piping and Electrical Work

CAUTION

For air supply, use pipes with an appropriate internal diameter so that pressure will not drop while

the valve is operating.

Failure to do so may result in poor valve performance.

Wiring work should be carried out only by qualified technicians following local electrotechnical

standards.

Cabling should be carried out in accordance with facility conditions. Use an adapter (and packing)

whose size is appropriate for the outer diameter of the cable.

If sealing tape is applied to air supply pipe threads, leave the two threads nearest the tip bare.

Clogging caused by pieces of tape may result in poor valve performance.

If liquid packing (thread lock sealant) is used for air supply piping work, do not allow it to enter

inside the pipes. If it does, poor valve performance may result.

Avoid doing wiring work on a rainy day or in high humidity.

Moisture inside connectors or the terminal box may cause a short-circuit or rust.

Handling Precautions

•

A packing (gasket) is attached to the cap of auxiliary equipment such as positioners. Do

not lose it during wiring work.

• If it is necessary to bend the air supply pipes, make gentle bends (using a dedicated tool

like a tube bender), and use a band to hold parallel pipes together.

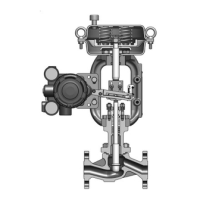

Positioner

2 threads

viii

Loading...

Loading...