Precautions for Assembly and Disassembly

WARNING

Before starting work, clean the inside of the valve, replace any residual gas, etc. Otherwise, the

residual fluid may cause an injury.

Do not disassemble the pneumatic actuator while supply air pressure is being applied. The

compressed air may cause an injury.

Because damaged or corroded bolts and nuts may damage the valve and cause injury, replace

them with new ones.

CAUTION

Observe the tightening torques indicated in the user's manual when tightening bolts and nuts.

For an actuator that incorporates springs, follow the disassembly procedure when removing bolts,

nuts, etc. Otherwise, the springs may jump out, causing injury.

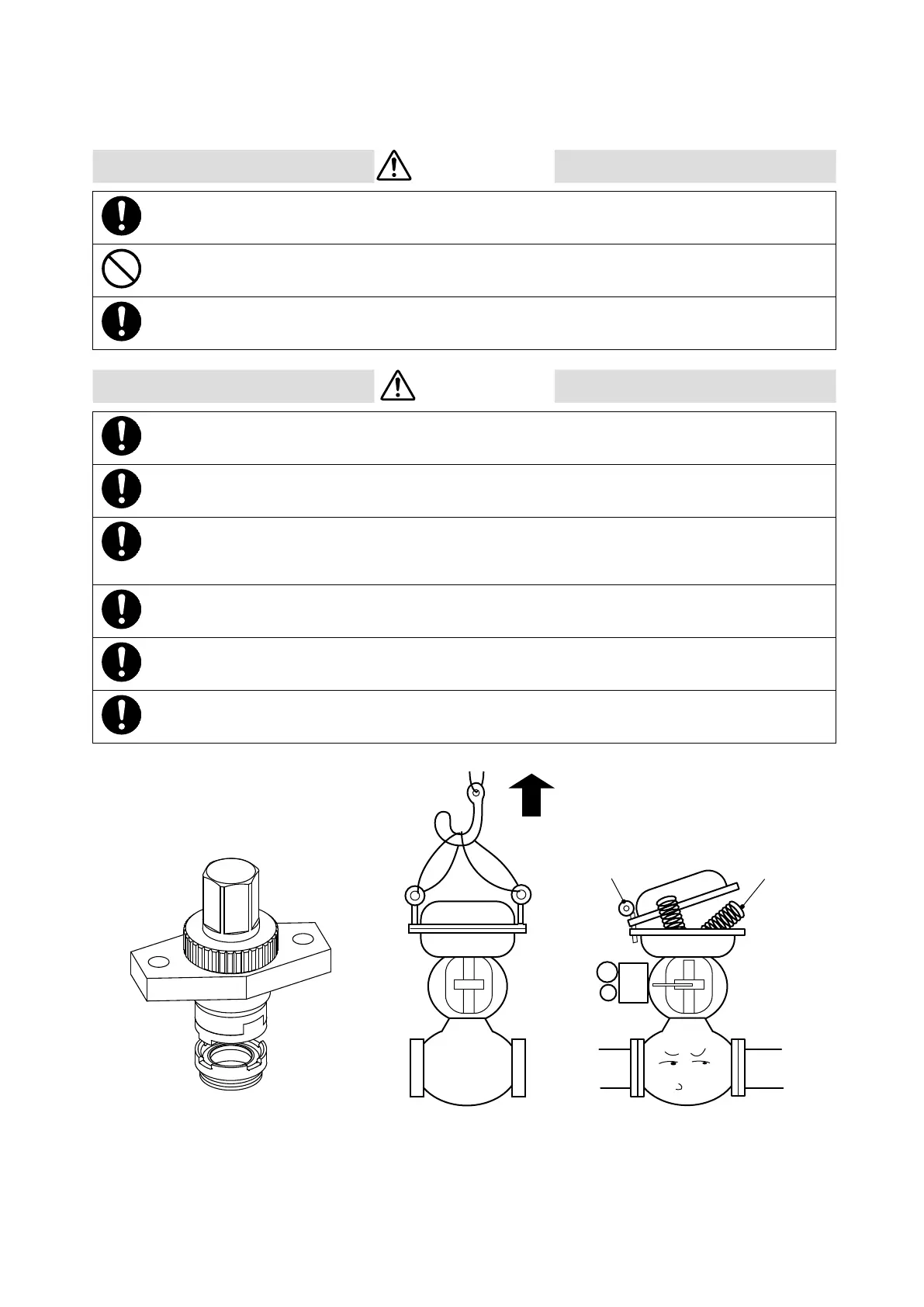

When removing the valve from the piping, if the eyebolts (eyenuts) attached to the actuator are

used to hoist the valve, make sure that the weight does not exceed the limit specified in the user's

manual. Otherwise, the valve may fall.

Before removing or attaching the trim (internal valve), check whether a dedicated tool is necessary.

If it is needed, be sure to use it. Otherwise, parts may be damaged.

Assemble the valve using the parts, bolts, nuts, etc., in the order stated in the assembly procedure.

Otherwise, malfunction may result.

When reassembling the valve body, always use new packing and gaskets. The reuse of old parts

will cause fluid leakage.

Eyebolt

Max. weight

Spring

Hoist

ix

Loading...

Loading...