Azbil Corporation

Model: AMT, HDT - CV3000 Series Control Valves

5

2. INSTALLATION

2.1 Maximum Lifting Loads of Eyebolts

The diaphragm case has a pair of lifting eyebolts. These eyebolts primarily are for

lifting the actuator alone. When using the eyebolts for other purposes (such as lifting

an actuator bed to its valve body or other components), note that the allowable

maximum lifting loads of the eyebolts are as shown in the following table.

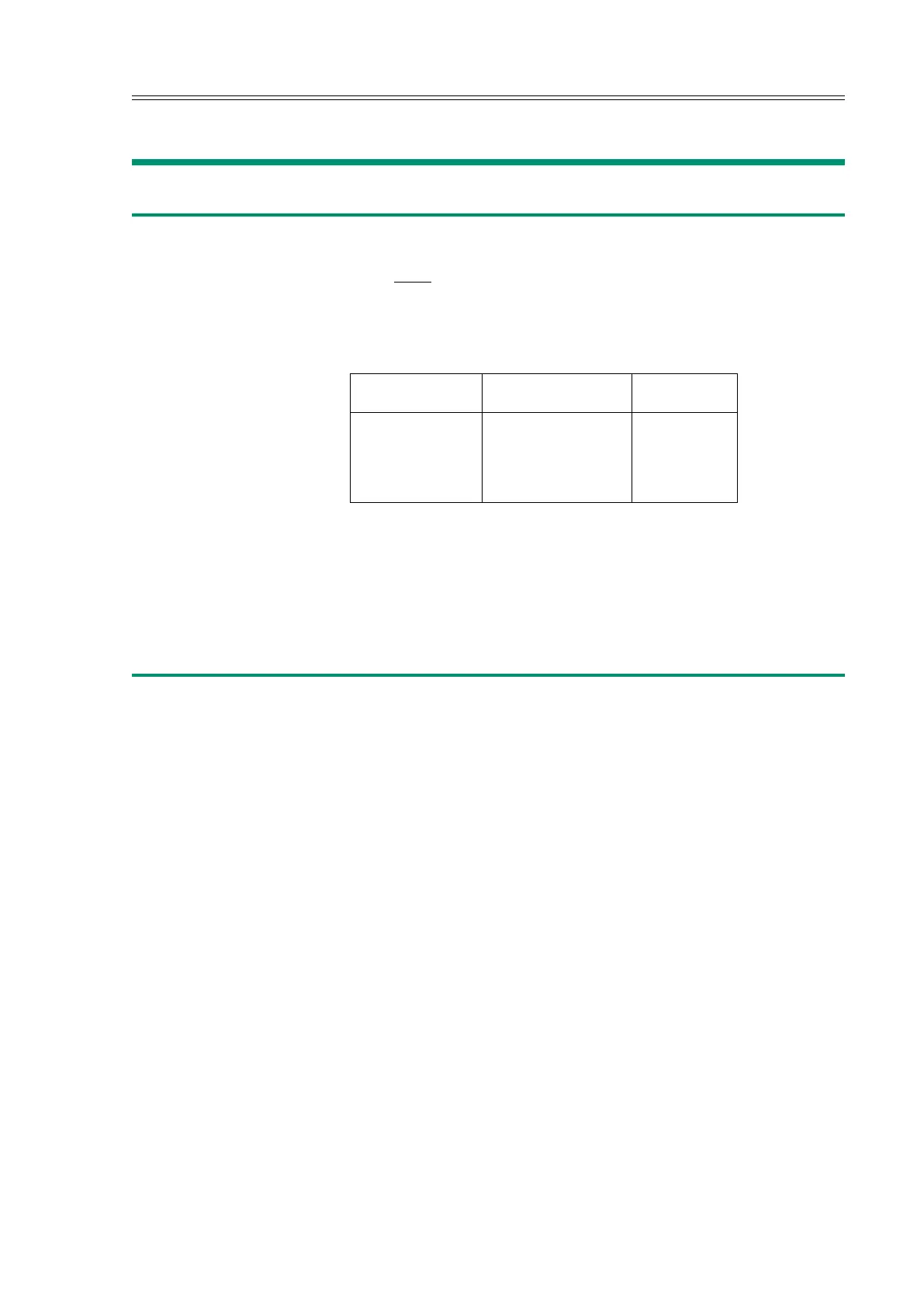

Table 2-1 Maximum Lifting Loads of Eyebolts

Actuator Model No.

Allowable Maximum

Lifting Load of Eyebolts

Weight of

Actuator Alone

PSA1 160kg 8kg

HA2 160kg 16kg

HA3 160kg 32kg

HA4 220kg 68kg

Note: The eyebolts may be used to lift the actuator together with its valve buy

(cast globe valve) of up to pressure rating “Class 600”. When doing this, be

extremely careful so that no shock or other abnormal force is applied to the

actuator or the valve body.

2.2 Installing Valve in Process Pipe

(1) Before installing the valve in the process pipe, remove foreign matter (such

as scales and welding chips) from both upstream and downstream sides of the

process pipe.

(2) Confirm that the direction of process fluid flow conforms with that of the

arrowhead mark provided on the valve body.

(3) Pay attention so that the pipe connection gaskets do not extrude into the process

pipe inside. Be sure to use gaskets made of material which is suitable for the

process fluid. The welding type of valve employ no gaskets.

(4) Pay attention so that no excessively large stress is conveyed from the process

pipe to the valve body. Uniformly tighten the bolts of the process pipe

connection flange. The high pressure type of valves have no flanges, since they

are connected to the process by welding.

(5) Before connecting the air pipes to the actuator and positioner, blow the pipes to

clean them.

(6) Do not install any heating or cooling provisions on the bonnet.

Loading...

Loading...