Azbil Corporation

Model: AMT, HDT - CV3000 Series Control Valves

11

(4) Mount the guide ring and two gaskets (since 1” valve has the guide mounted in

the bonnet and 1 1/2” and 2” valve in the valve body, only one gasket is used)

from the top of the valve body and install the bonnet.

For assembling the tail piece and the bonnet with nuts, first tighten all nuts

lightly with a and further, gradually tighten them with a wrench evenly not to

cause uneven tightness.

(5) Insert the gland packing into the gland. (See Fig. 2-1.)

Note: When installing yarn packings, stack them sheet by sheet with the cut

sections of the mutally adjoining sheets making up the right angle (90

degrees).

(6) Install the packing follower and packing flange, and tighten the nut. For the

tightening torque, see Table 2-2.

• HDT (Diverting) Type (Refer to Fig.4-4.)

To assemble the valve, follow the disassembly procedure in the reverse order.

(1) To mount the seat ring, use the “special tool for mounting and removing the seat

ring.” For the tightening torques, see Table 4-1.

(2) Insert the valve plug A (with valve stem mounted) from the top of the bonnet.

(3) Insert the gasket and seating guide from the tail piece side and, then,fasten the

valve pulg B with the lock nut.

(4) Insert the gasket and assemble the tail piece.

(5) Mount the guide ring and two gaskets from the top of the valve body and

assemble the bonnet.

For assembling the tail piece and the bonnet with nuts, first tighten all nuts

lightly with a and further, gradually tighten them with a wrench evenly not to

cause uneven tightness. For the tightening torque, see Table 4-2.

(6) Insert the gland packing into the gland. (See Fig. 2-1.)

Note: When installing yarn packings, stack them sheet by sheet with the cut

sections of the mutally adjoining sheets making up the right angle (90

degrees).

(7) Install the packing follower and packing flange, and tighten the nut. For the

tightening torque, see Table 2-2.

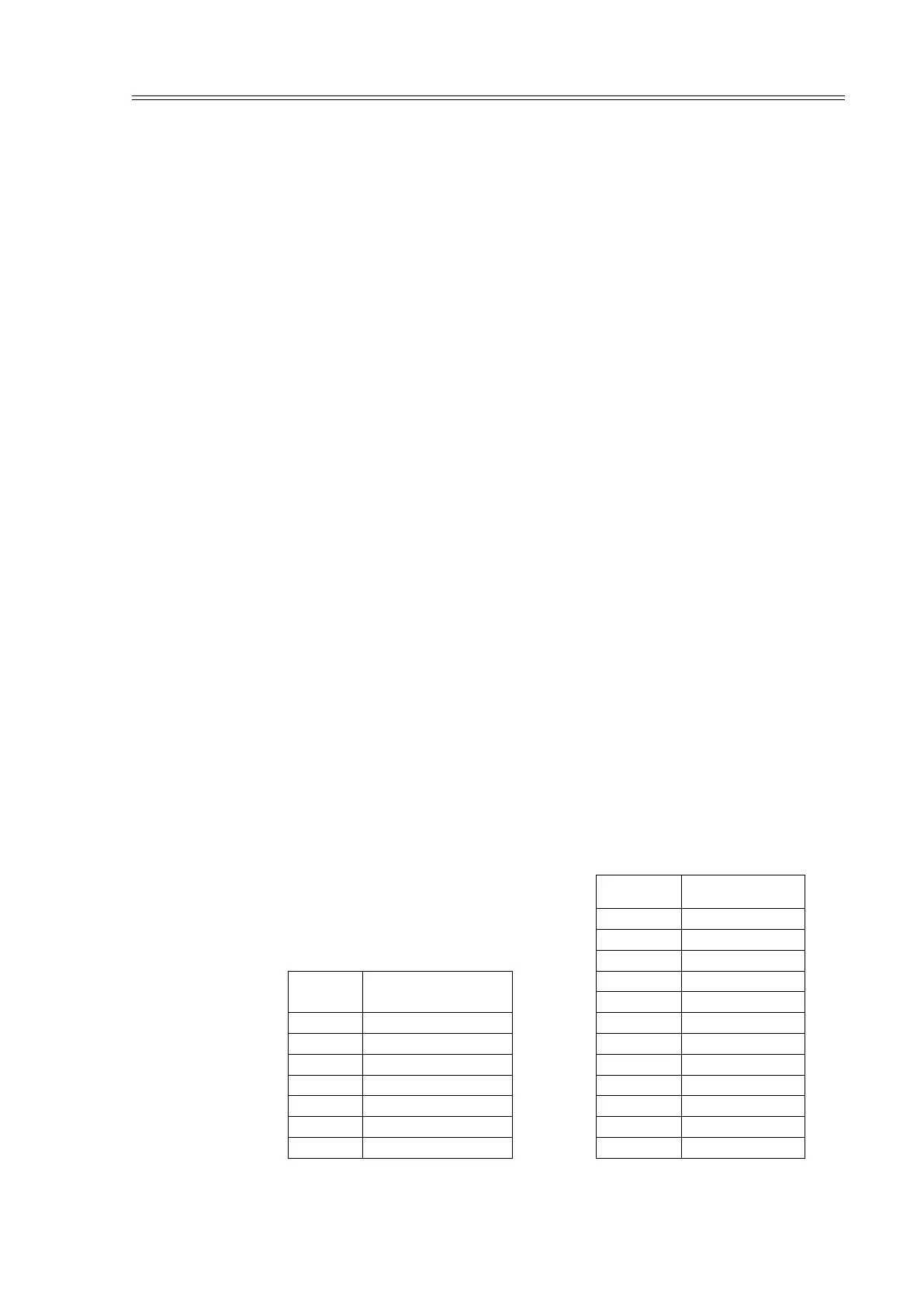

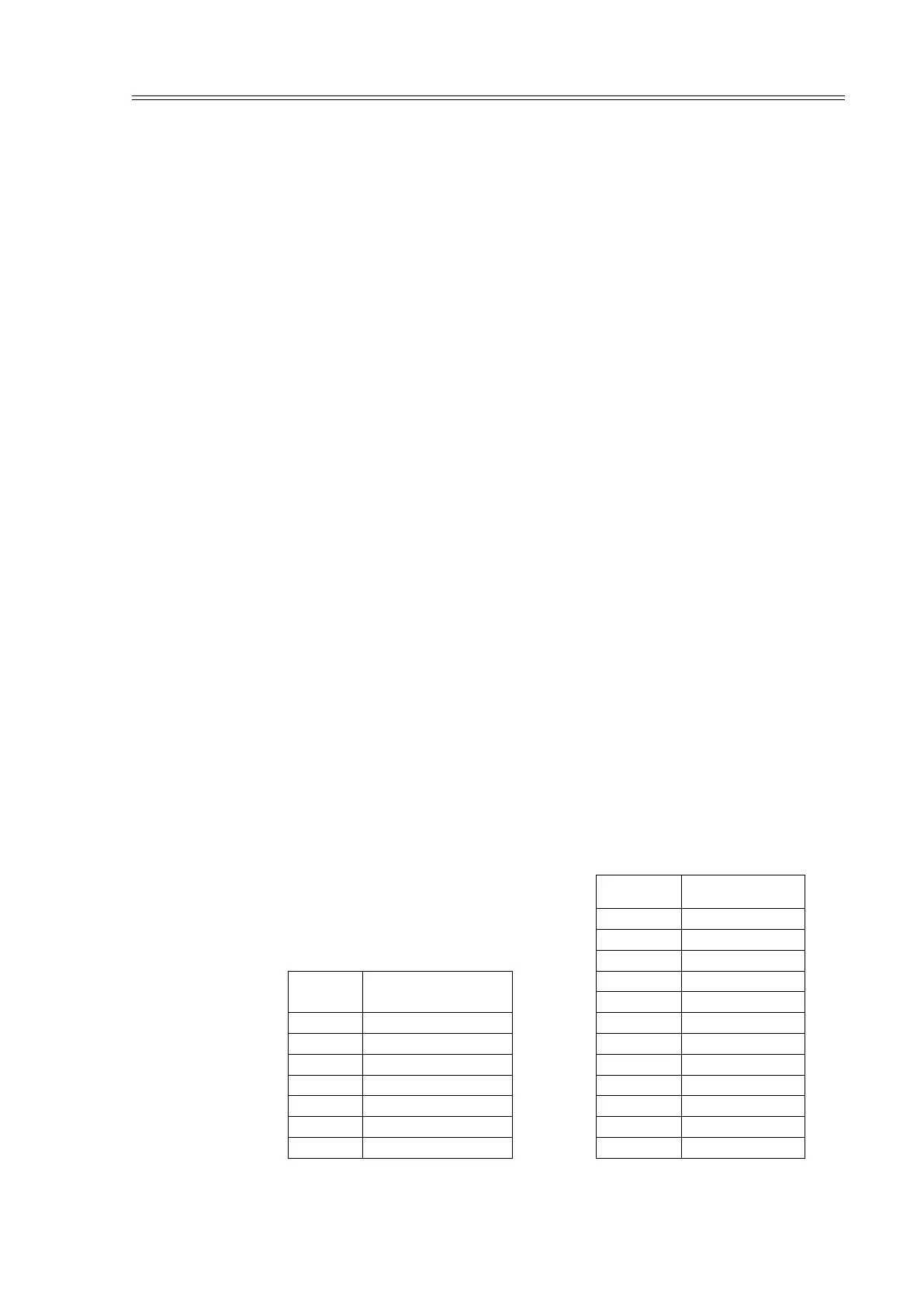

Bolt

Torque

(N.m{kgf-cm})

M12 60 {600}

M16 100 {1,000}

M20 150 {1,500}

Size (in.)

Torque

(N.m{kgf-cm})

M22 200 {2,000}

M24 250 {2,500}

1 180 {1,800}

M27 350 {3,500}

1-1/2 260 {2,600}

M30 500 {5,000}

2 390 {3,900}

M33 660 {6,600}

2-1/2 520 {5,200}

M36 850 {8,500}

3 650 {6,500}

M39 1,000{10,000}

4 800 {8,000}

M42 1,200 {12,000}

5 1,000 {10,000}

M45 1,400 {14,000}

Table 4-1 Seat Ring Tightening Torques Table 4-2 Tightening Torque of

Bonnet Stud Bolts

Loading...

Loading...