Mounting space ●

Keep a sufficient space to allow easy maintenance and inspection, and service work.

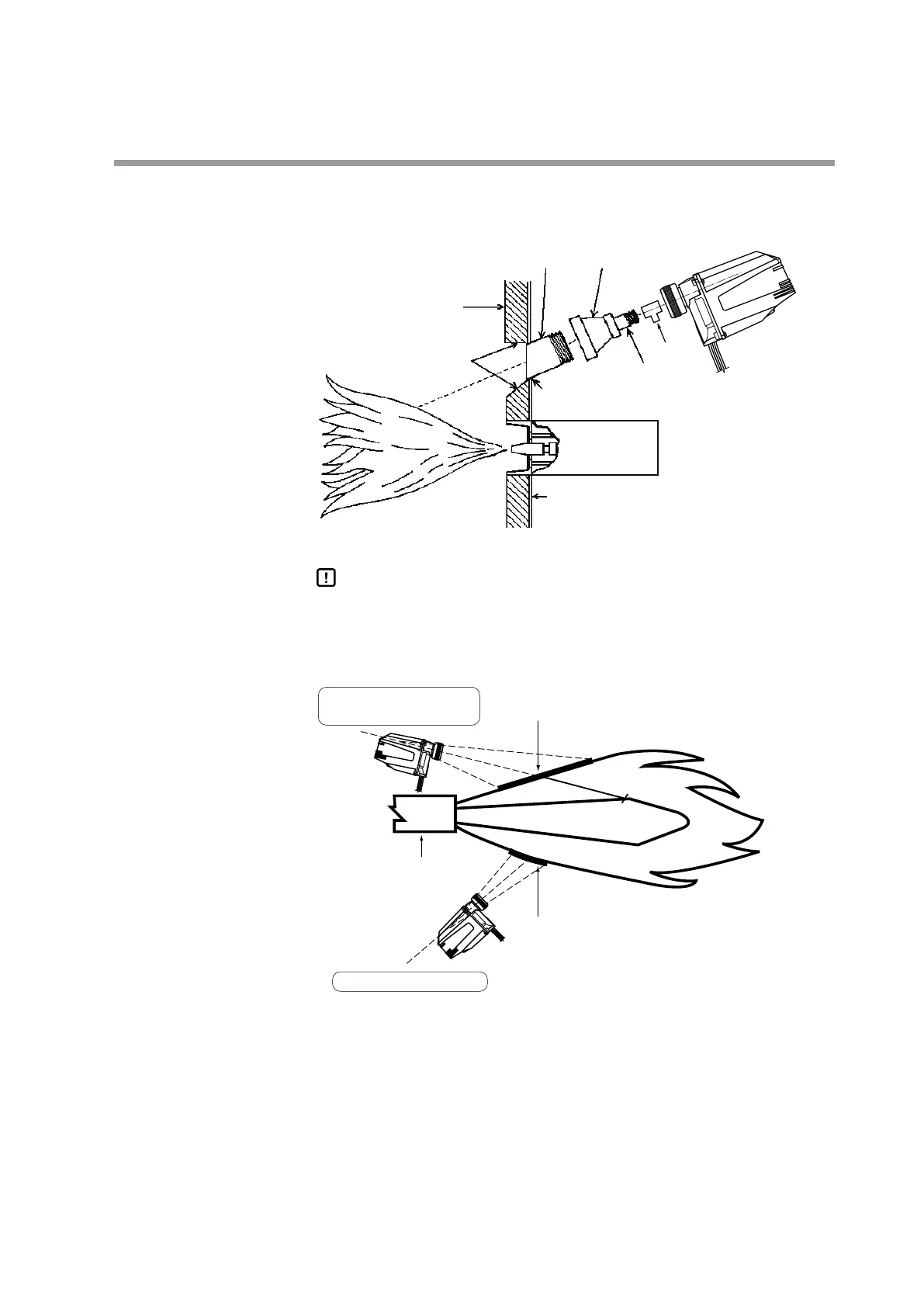

Monitoring pipe,

1" or more

(Use 2" to 3" pipe.)

Reducing socket

AUD300C

Connection

nipple (1")

Weld this

part

Burner

Plate

Tapered monitoring hole

*

* If the air purging is needed, tees are used to supply the air.

Furnace wall

Air

*

Tees

Handling Precautions

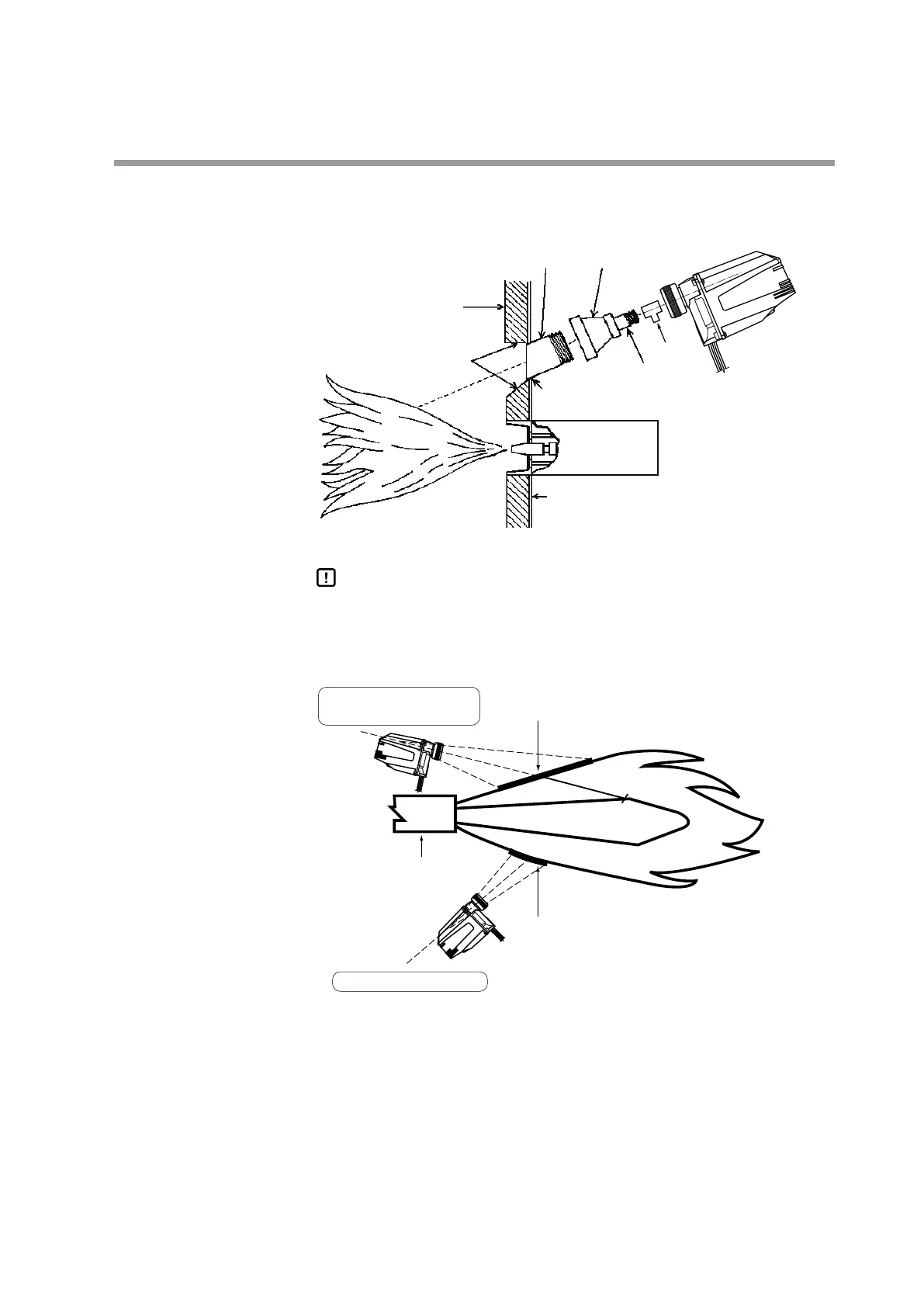

Mount this unit so that its monitoring direction intersects the flame axis •

at an as small angle as possible. This ensures a wide intersection area of

the monitoring area between the flame and this unit. Thus, the detection

amount of ultraviolet ray radiation becomes large.

Flame surface area monitored is small.

Unburnt fuel

Flame surface area monitored is large and

much ultraviolet radiation is detected.

Burner

Good sighting position

(low angle sighting)

Poor sighting position

Temporary welding for positioning of monitoring pipe ●

(1) Prepare the monitoring pipe and make the mounting hole.

Make the mounting hole for the monitoring pipe at the selected monitoring pipe

mounting position.

Perform the screw threading of one end of the monitoring pipe and cut the

monitoring pipe to a desired length so that its length is as short as possible.

Loading...

Loading...