1

Chapter 1. OVERVIEW

Overview ■

The AUD300C1000 Advanced Ultraviolet Flame Detector (hereafter referred to as

the AUD300C) is designed to detect ultraviolet radiation from an oil or gas burner

flame, for use with both batch and continuous operation. The AUD300C is used in

combination with a dedicated burner controller. By means of the built-in shutter,

any malfunction of the UV flame detector or burner controller is detected by the

continuous self-checking (Dynamic Self-Check) function, ensuring highly reliable

combustion safety control.

Features ■

• Maintenance parts such as the tube unit and shutter unit can be handled as a

single unit. This ensures easy replacement and maintenance work.

• As for a flame sensor for the self-check, this unit is compact and lightweight. This

ensures free burner mounting.

• The operating ambient temperature is 100 °C (up to 120 °C during flame detec-

tion) and the protection structure is IP66. This ensures excellent environment-

proof performance.

• The vertical mounting is possible and the maximum wiring distance is 200 m.

This ensures flexible construction work.

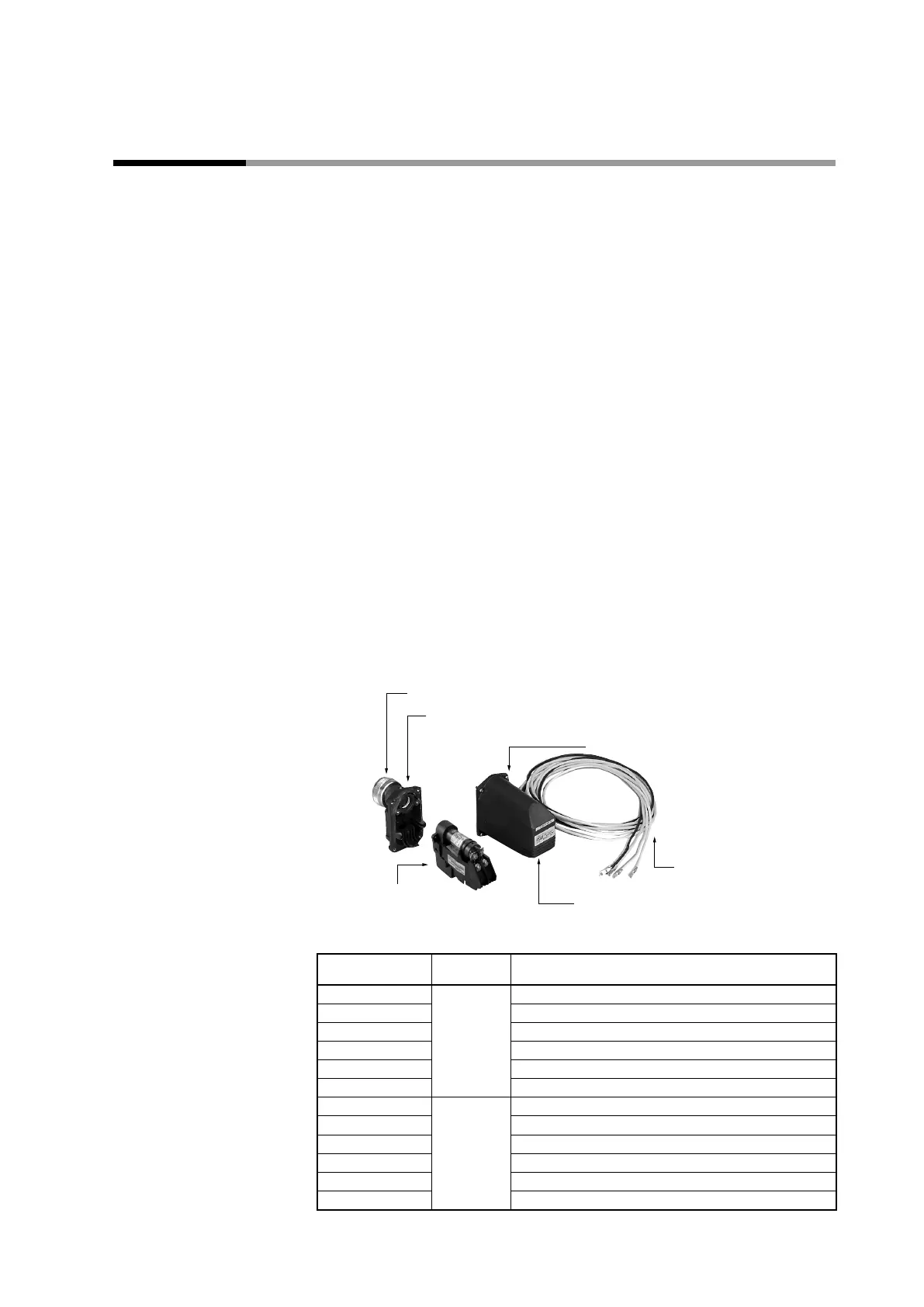

Part names ■

Main unit ●

Mounting nut

Flange unit

81446924-001 or -101

Lead wires

Cover mounting screws (4)

Cover

AUD Maintenance Kit

AUD60A1000

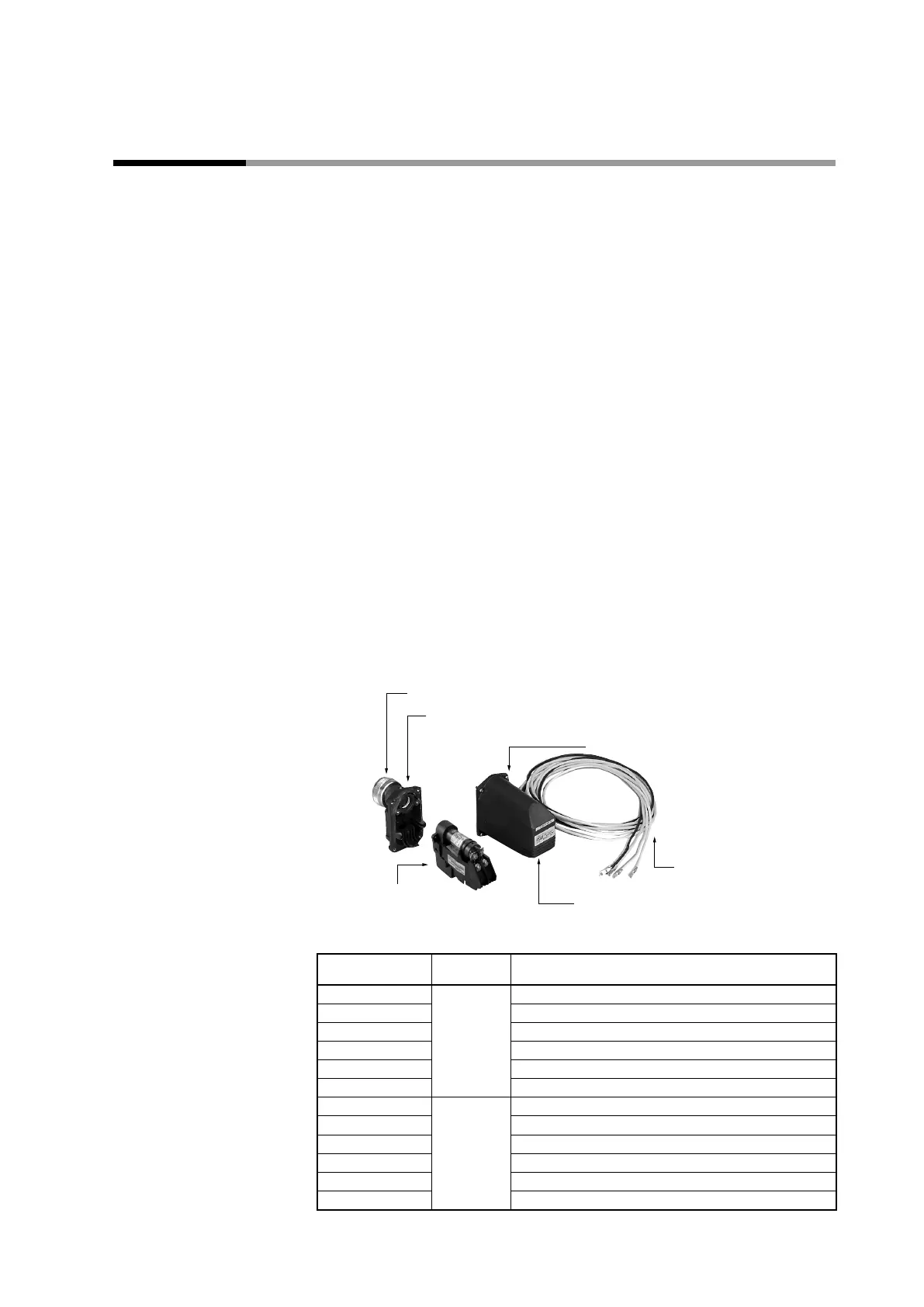

Model No. ■

Model No. Lens type Additional

AUD300C1000

Standard None

AUD300C100D

Inspection report

AUD300C100T

Tropicalization treatment

AUD300C100Y

Traceability certificate

AUD300C100DT

Inspection report + tropicalization treatment

AUD300C100YT

Traceability certificate + tropicalization treatment

AUD300C1100

Condenser None

AUD300C110D

Inspection report

AUD300C110T

Tropicalization treatment

AUD300C110Y

Traceability certificate

AUD300C110DT

Inspection report + tropicalization treatment

AUD300C110YT

Traceability certificate + tropicalization treatment

Loading...

Loading...