19

Specification ■

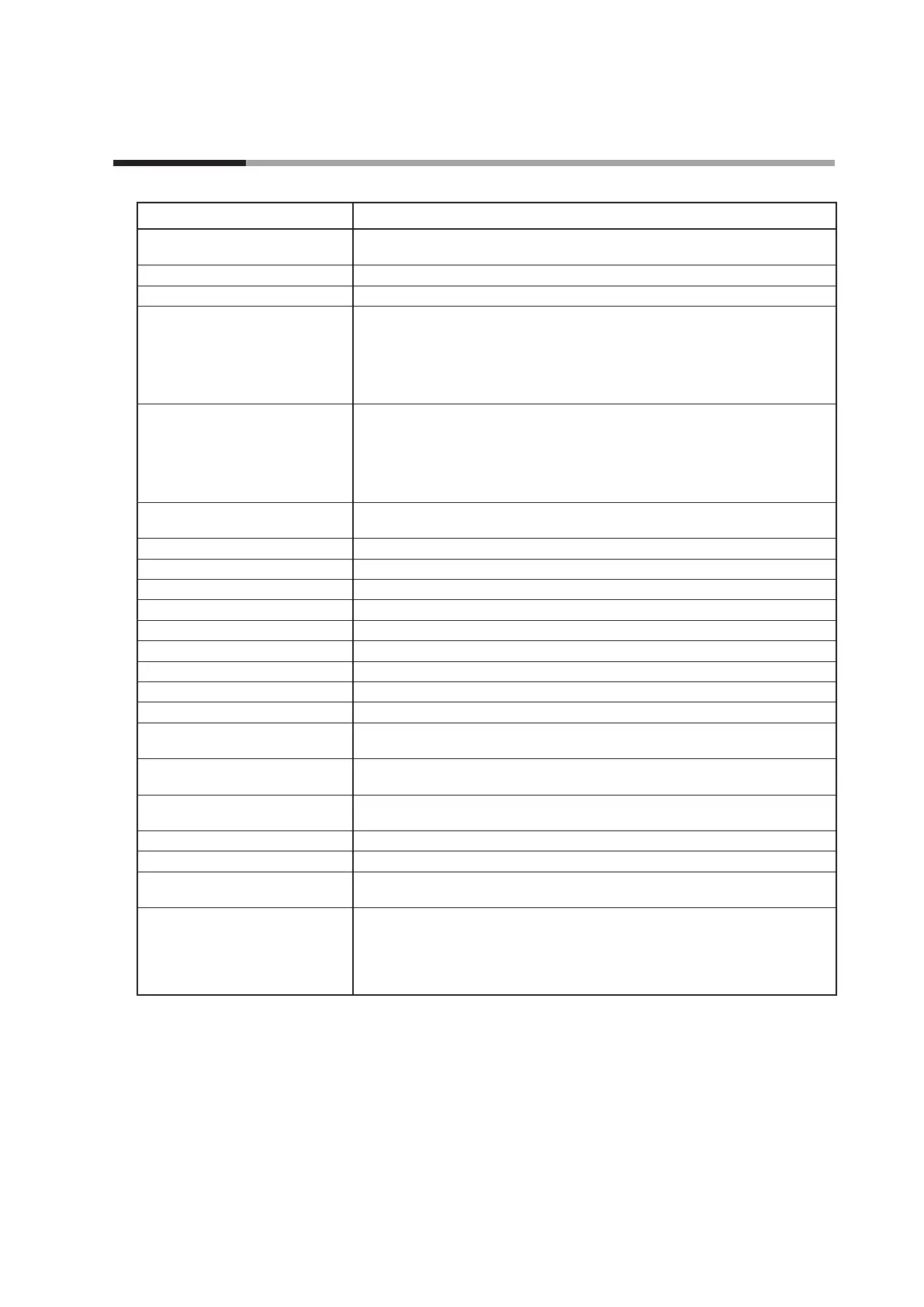

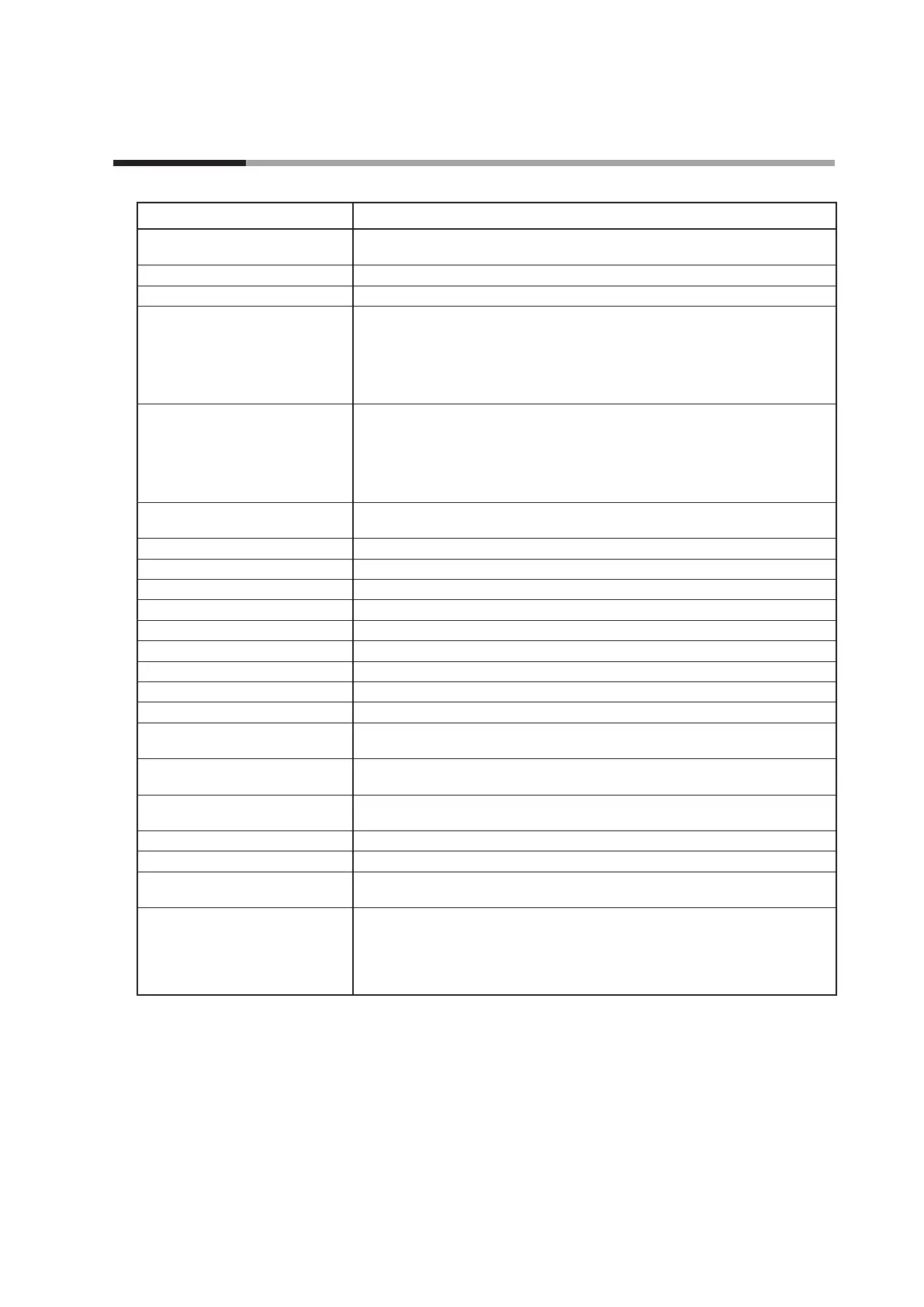

Item Description

Applicable types of flame *

1

City gas, Natural gas, Propane gas, Kerosene, Heavy oil, Coke oven gas, Hydrogen,

Chlorine, Ammonia, Naphtha, Ethylene, etc.

Shutter voltage Approx. 24 Vdc (supplied from burner controller)

Self-checking cycle Approx. 80 cycles/min

Insulation resistance Between flange unit mounting conduit and F-terminal (or blue lead wire),

between flange unit mounting conduit and G-terminal (or yellow lead wire),

between flange unit mounting conduit and S1-terminal (or white lead wire),

between flange unit mounting conduit and S2-terminal (or white lead wire):

50 MΩ min. by 500 Vdc megger at the above each location.

(However, the tube unit must be removed.)

Dielectric strength Between flange unit mounting conduit and F-terminal (or blue lead wire),

between flange unit mounting conduit and G-terminal (or yellow lead wire),

between flange unit mounting conduit and S1-terminal (or white lead wire),

between flange unit mounting conduit and S2-terminal (or white lead wire):

1500 Vac for 1 min or 1800 Vac for 1 sec at the above each location.

(However, the tube unit must be removed.)

Ambient temperature –20 to +100 °C

During flame detection, the maximum allowable ambient temperature is +120 °C.

Ambient storage temperature –20 to +70 °C

Ambient storage humidity 90 % RH at 40 °C max. (without condensation)

Vibration resistance 4.9 m/s

2

max., 10 to 55 Hz for 2 hours each in X, Y and Z directions

Impact resistance 300 m/s

2

in vertical and horizontal directions

Pressure resistance for flange 350 kPa

Protection IP66 (except a conduit tube connection port)

Mounting posture –45 to +90° (in vertical direction)

Mounting G1 (at the mounting section for monitoring pipe)

Lead wires AWG18 heat resistant silicone cables, with applox. 1.8 m color lead wires (4 pcs)

Electric wire pipe mounting

conduit

1/2-14NPSM

Flame signal wire requirements and

extension distance

Requirements: 600 V vinyl insulation wires, IV wires with 2.0 mm

2

, 200 m max.

Materials Main body: Heat resistant resin (PPS + PPE + GF40)

Mounting section: Aluminum

Main body color Purple (equivalent to DIC257)

Mass Approx. 630 g

Expiration date of tube unit and

shutter unit

3 years

Certification Gas Appliance Directive(CE)*

2

: 0063BS1427(with AUR450C and Q241A104)

0063CN6671(with RX-R4_C series)

UL: File No. MH27717

CSA: Master Report LR 078402

Note. Certification does not apply to AUD300C1_ 0Y and AUD300C1_0YT.

*1 For applications using coke oven gas, hydrogen, chlorine, ammonia, naphtha, ethylene, etc., in which the burner

structure may impose restrictions on the mounting of the flame detector, it is necessary to check that flame monitor-

ing is reliable.

*2 CE marking appears only on the controller.

Chapter 7. SPECIFICATION

Loading...

Loading...