Valve Positioner Azbil Corporation

4-10 Model VFR - FloWing Eccentric Rotary type Control Valves

4-2-6 : Adjusting the positioner

The positioner installed on a valve has been factory adjusted before shipment. When

it has been replaced, however, the newly installed positioner is required to be adjusted

in the following procedure.

(1) Switch the bypass cock to “ON”.

(2) Conrm the positioner input air pressure range, supply air pressure and actuator

spring range by referring to the nameplate.

(3) Feed the supply air to the posiitoner.

(4) The procedures hereunder are divided into steps for a direct-action positioner and

those for a reverse-action positioner, and assume an input air pressure range of

20-98 kPa{0.2-1.0 kg/cm²} for both cases.

*1: If the input air pressure range of the positioner is 20-60 kPa{0.2-0.6 kg/cm²},

substitute 98 kPa {1.0 kg/cm²} with 60 kPa {0.6 kg/cm²} and 20 kPa {0.2 kg/

cm²} with 60 kPa {0.6 kg/cm²} in the following steps.

For direct action positioner (air-to-open)

(5) Set the input air pressure to 20 kPa {0.2 kg/cm²}.

(6) Turn the zero adjustment knob so that the output pressure of the positioner

becomes the lower limit of the actuator spring range. When this is done, the

indicator will indicate “S”.

(Example: If the spring range of the actuator is 98 - 200 kPa {1 - 2 kg/cm²}, set

the output pressure of the positioner to 98 kPa {1 kg/cm²}.)

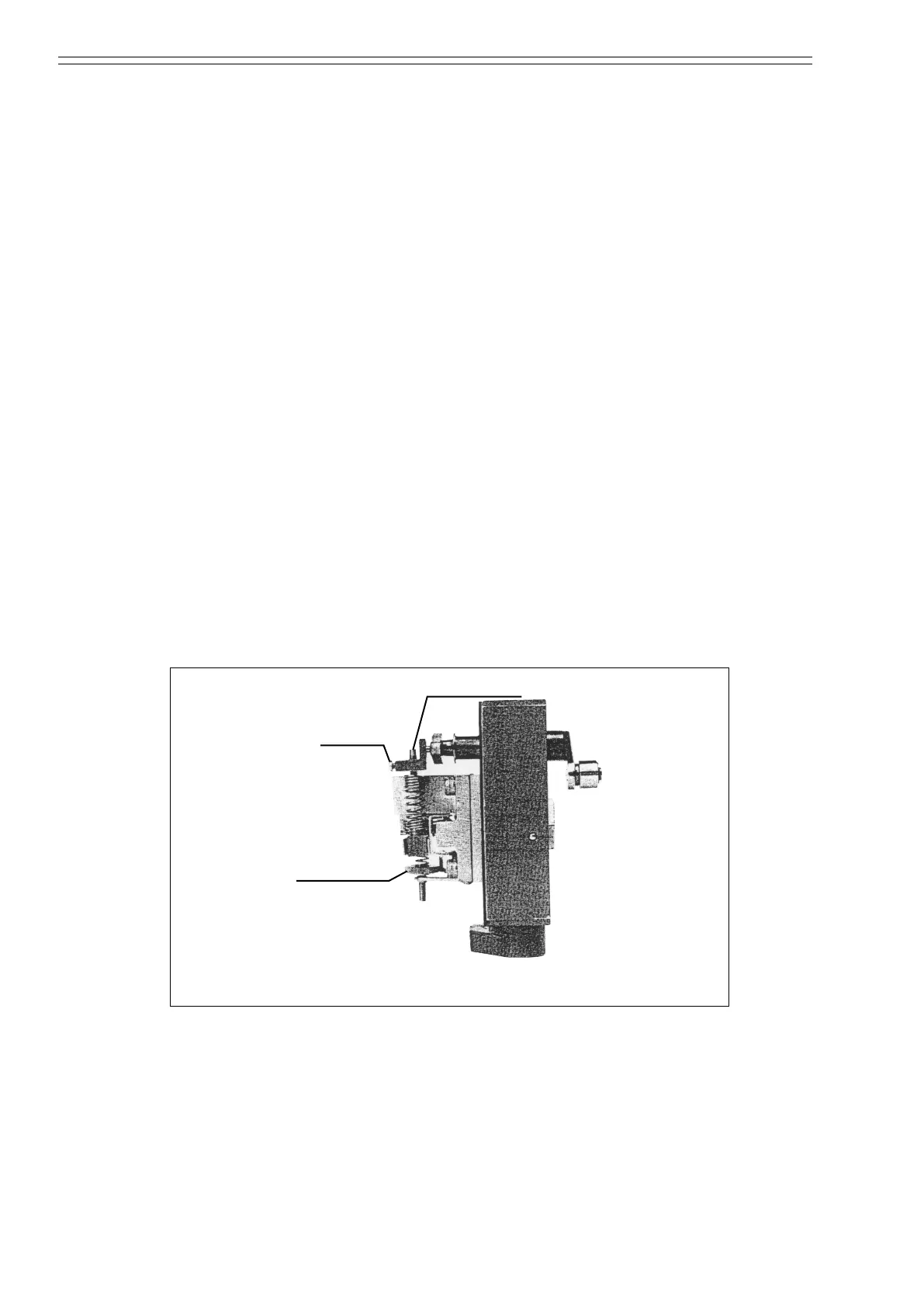

Lock screw

Figure 4-19 Adjusting the positioner

(7) Set the input air pressure to 98 kPa {1.0 kg/cm²}.

(8) Loosen the lock screw with a screwdriver (-) and adjust the SPAN control so that

the indicator indicates “0”.

For direct action positioner (air-to-close)

(5) Set the input air pressure to 98 kPa {1.0 kg/cm²}.

Loading...

Loading...