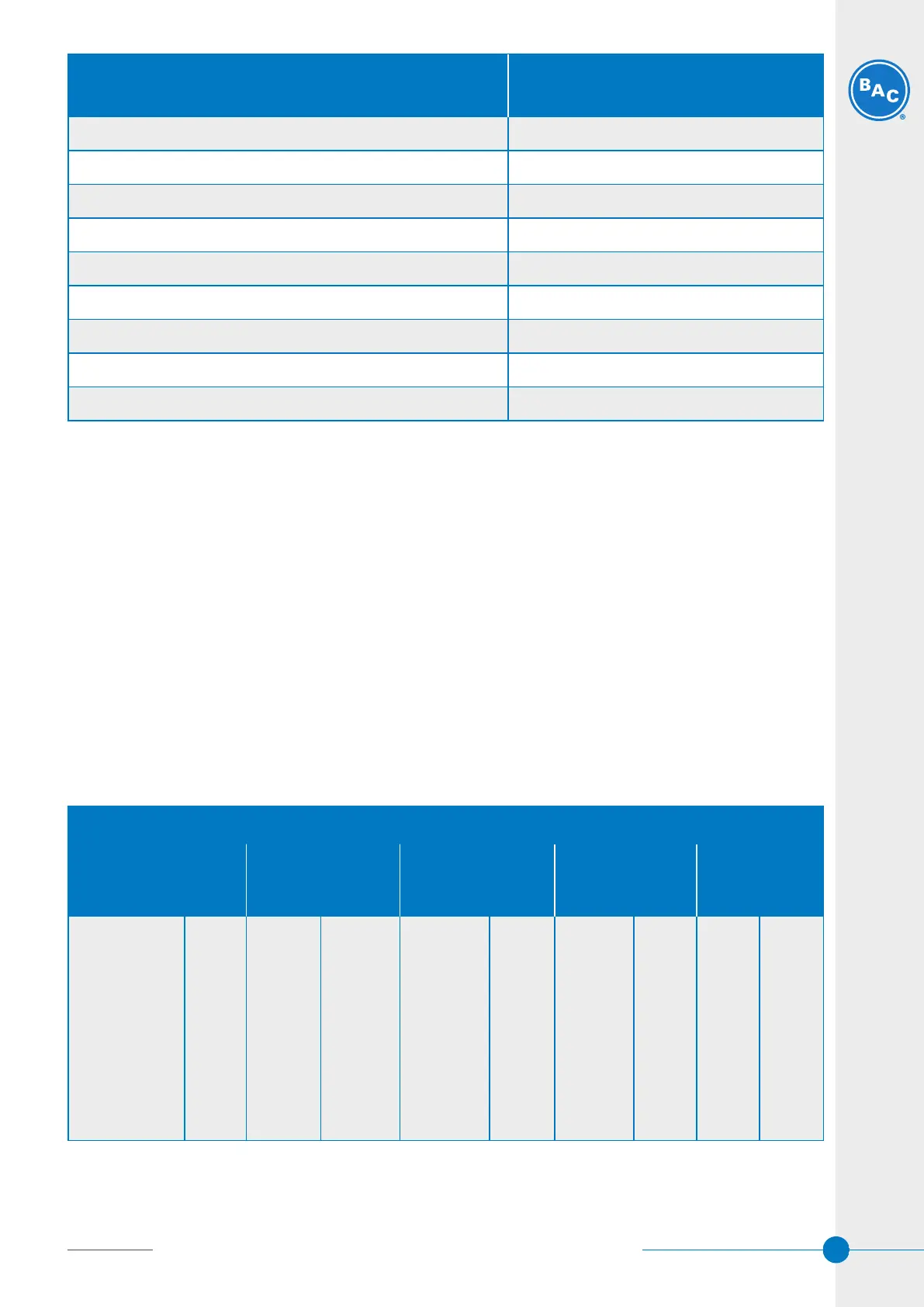

Water quality guidelines for adiabatic

pre-cooler Frame

Baltibond

®

Hybrid Coating

Temperature < 20 ºC

PH 6.5 – 9

Hardness as (CaCO

3

) 30 – 500 mg/l

Alkaline as (CaCO

3

) < 500 mg/l

Total dissolved solids < 1500 mg/l

Chlorides < 200 mg/l

Sulfates < 300 mg/l

Conductivity 1800 µS/cm

Bacteria Rate (CFU/ml, KBE/ml) < 1000

Minimum supply water quality

For Ozone water treatment application:

• Stainless steel 316L execution is required.

• Ozone levels are to be maintained to 0.2 ppm ± 0.1 ppm for at least 90% of the time, with absolute maximum

peaks of 0.5 ppm

Recommended adiabatic pre-cooler water flow rates

If any of the following happens:

• at ambient conditions exceeding the given maximum ambient conditions,

• with supply water quality data exceeding one or more of the concentration limits of above table "Minimum

supply water quality",

• if the supply water has a Practical Scaling Index below 5.5,

Then:

• the water flow needs to be increased to higher levels to avoid rapid fouling and scaling of the pre-cooler

medium. Contact your local BAC-Balticare representative for support.

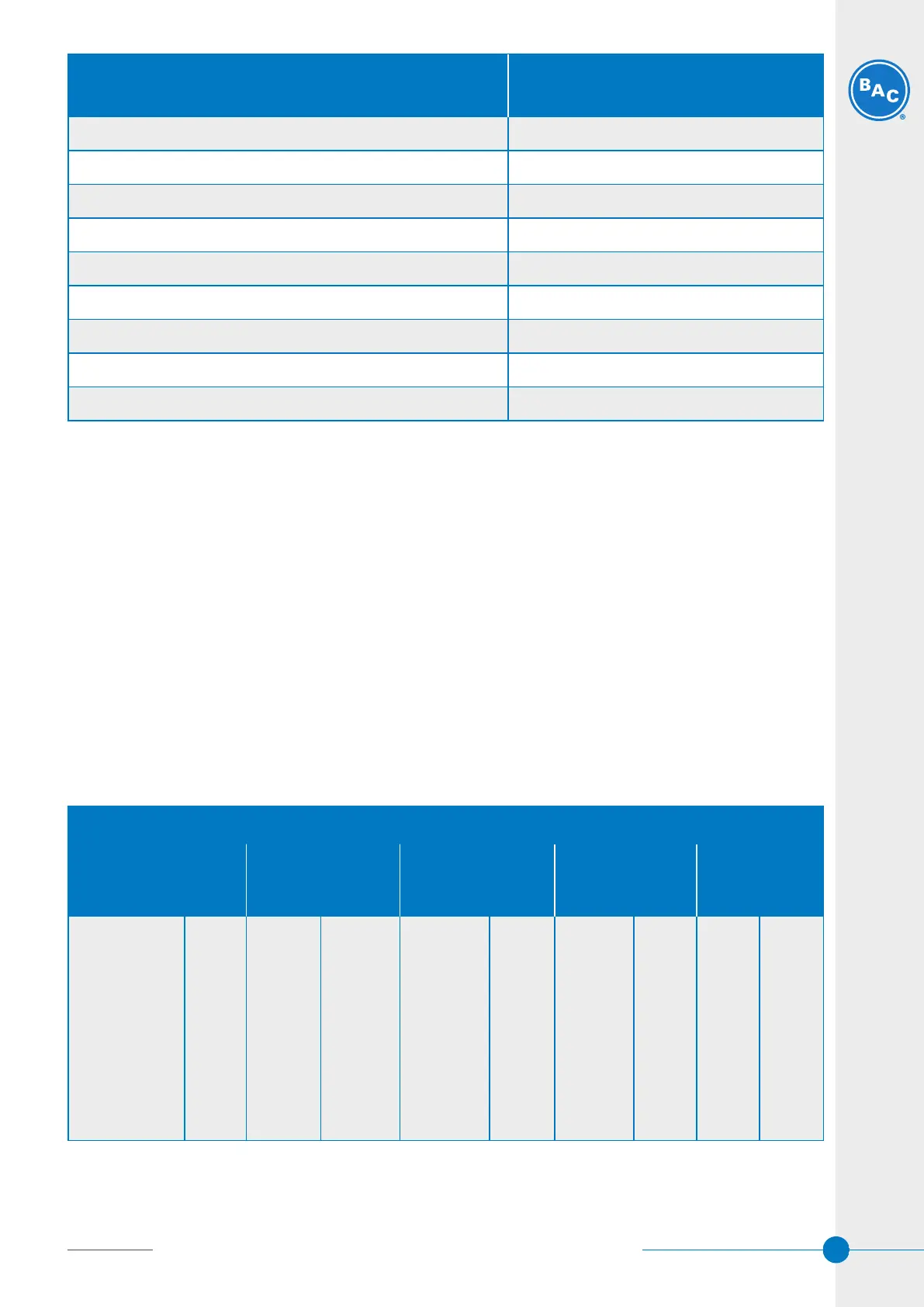

Data for rapid calculations of Practical Scaling Index for adiabatic pre-cooler

Conductivity

(µS/cm)

A

Temperature

ºC

B

Calcium hardness

(PPM as CaCO

3

)

C

Total alkalinity

(PPM as CaCO

3

)

D

Alkalinity

(PPM as CaCO

3

)

pHeq

50-300

301-1000

1001-3000

3001-5000

0.1

0.2

0.25

0.27

10-13

14-17

18-21

22-27

2.3

2.2

2.1

2.0

10-15

16-25

26-40

41-70

71-100

101-140

141-200

201-250

251-300

301-350

351-400

401-450

451-500

0.70

0.90

1.10

1.35

1.55

1.70

1.85

1.95

2.05

2.12

2.18

2.24

2.28

10-15

16-25

26-40

41-70

71-100

101-140

141-200

201-250

251-300

301-350

351-400

401-450

451-500

1.10

1.30

1.50

1.75

1.90

2.10

2.25

2.35

2.45

2.52

2.58

2.63

2.68

50

100

200

300

400

500

7.0

7.5

7.9

8.2

8.4

8.5

Calculation of Practical Scaling Index

W W W . B A L T I M O R E A I R C O I L . E U

9

3 Water care

3 Water care

Loading...

Loading...