Document: 333D012G

5-18-2007

- 21 -

Cleaning and Disinfecting Stainless Steel

Simple Cleaning

IMPORTANT

Do not use steel wool or steel pads when cleaning stainless steel.

Dirt deposits on stainless steel (dust, dirt and finger marks) can easily be removed. Frequently, warm water, with or

without detergent, is sufficient. If this does not remove the deposits, mild, non-abrasive household cleaners can be

used with warm water and bristle brushes, sponges or clean cloths.

Iron rust discoloration can be treated by rubbing the surface with a solution of 15% to 20% by volume of Nitric

Acid and water and letting it stand for one to two minutes to loosen the rust.

Disinfection

The purpose of disinfection is to destroy particular organisms that could pose a potential hazard to humans or

compromise the integrity of the experiment. It is important to use a suitable disinfectant in the concentration

appropriate to the organism being killed. Standard disinfectants include: Hypochloride (chlorine bleach), Iodophor-

Detergent, Ethanol, Phenol and Alcohol.

IMPORTANT

Rinsing in sterile hot water and wiping the surface completely dry should always follow disinfection and

cleaning.

Disinfect the work surface before and after every procedure.

1. Disinfect surfaces of all equipment used.

2. Remove all items from the inside of the cabinet.

3. Place all items that may have come in contact with the agent(s), such as used pipettes, in a plastic bag or

other suitable container.

4. Disinfect the entire inside surface of the cabinet.

For additional information on cleaning and disinfecting stainless steel, please refer to: “Decontamination,

Sterilization, Disinfection, and Antisepsis”, Vesley, Donald and Lauer, James L., Laboratory Safety Principles and

Practices, Second Edition, 1995, Fleming, D.O., Richardson, J.H., Tulis, J.J. and Vesley, D., editors, ASM Press,

Washington, D.C., pp. 219-237; and Biosafety Reference Manual, Second Edition, 1995, Heinsohn, P.A., Jacobs,

R.R. and Concoby, B.A., editors, AIHA Publications, pp.101-110.

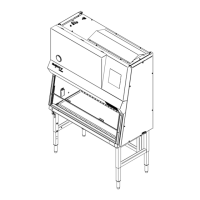

Using Ancillary Equipment

The rule to keep in mind is that the more equipment placed in the cabinet, the greater will be the air turbulence it

causes. The turbulence resulting from equipment and materials can disrupt the designed airflow and reduce the

effectiveness of the cabinet. When you use equipment which rotates, vibrates or heats, be sure to place it at the rear of

the work area if possible. This will help minimize the turbulence at the access opening.

Loading...

Loading...