12 english

4

Installation and connection (continued)

4.2.3 Installing the BTL

NOTICE

Interference in function

Improper installation can compromise the function of the

BTL and result in increased wear.

► The mounting surface of the BTL must make full

contact with the supporting surface.

► The bore must be perfectly sealed (O-ring/flat seal).

► Check the suitability of the O-ring for the specific

application.

► If installed in a hydraulic cylinder outside of zone0,

the magnet should not make contact with the rod.

Protect the rod from damage and wear.

1. Unscrew and remove housing cover.

2. For secure fastening, tighten the BTL with hexagon

socket screws M6x45 A4 or 1/4"-20x1-3/4" at all 6

mounting holes (torque 3.5 Nm or 2.6ft∙lb).

3. Connect wiring (see Electrical connection on page 14).

4. Re-install the housing cover and tighten to 33…40Nm

(25…30ft∙lb). Tighten secondary retaining screws

(ATEX).

► Install the magnet (Accessories).

► From 500mm nominal length: support the rod

and tighten it at the end if necessary.

4.3 Application2: fill level measurement in zone0

(with float, according to Section 12.1)

4.3.1 Preparing for installation

Installation variant: For holding the BTL and float we

recommend non-magnetizable material.

Avoid magnetic field interference at the screw-in thread,

e.g. by the weld seam at the threaded flange!

Install the BTL in such a manner that only the rod extends

into the explosive area of zone0 and the body and

electronics remain behind a separating wall in the explosive

area of zone1.

The spacer ensures that the float does not move into the

damping zone in the bottom end of the rod.

The depth of the mounting hole must be at least 25mm

(see Fig. 4-4).

4.3.2 Installing the linear position sensor

Installing the float

Important notes

– Only the floats listed under Accessories may

be used as magnets in zone0 (see

Section 12.1).

– Design measures ensure that the floats are

electrically connected with the rod in any

position. The specified installation position

must be observed!

– Only use the cotter pin once!

1. Install the float (accessory) taking the orientation into

account (raised markings on top, see Section 12.1).

2. Secure the float using the cotter pin (included in the

scope of delivery of the float), without placing any

mechanical loads on the rod. Insert the cotter pin

through the hole and hold it at the eye with a pair of

pliers. With a second pair of pliers, bend the straight

ends of the cotter pin around the rod one after another.

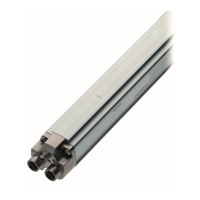

BTL7-A/C/E/G5_ _-M_ _ _ _-J-DEXC-TA12

Magnetostrictive Linear Position Sensor – Rod Style

Type of protection “db” and “ta”

Flameproof enclosure

Loading...

Loading...