22 english

b

a

b

8

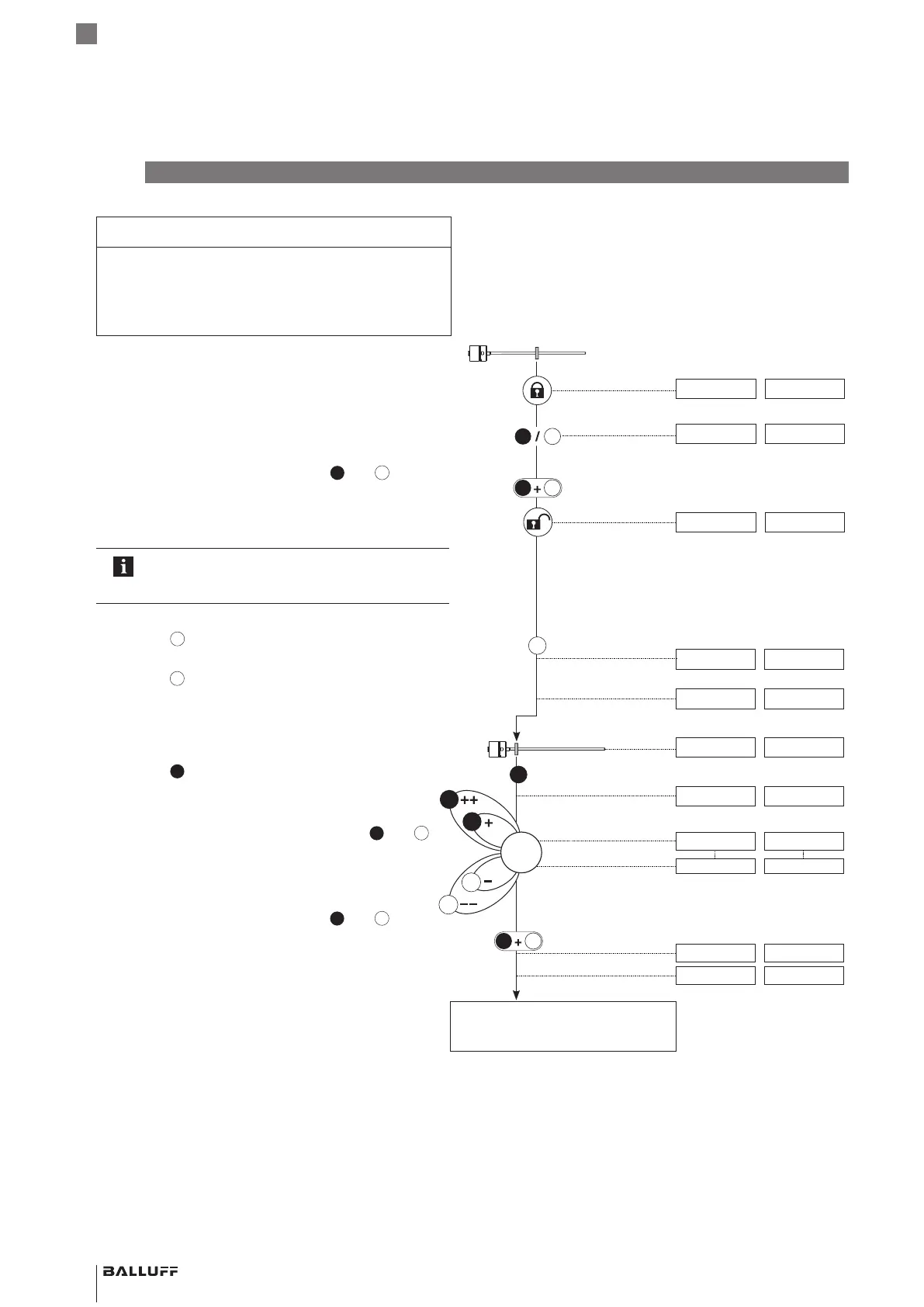

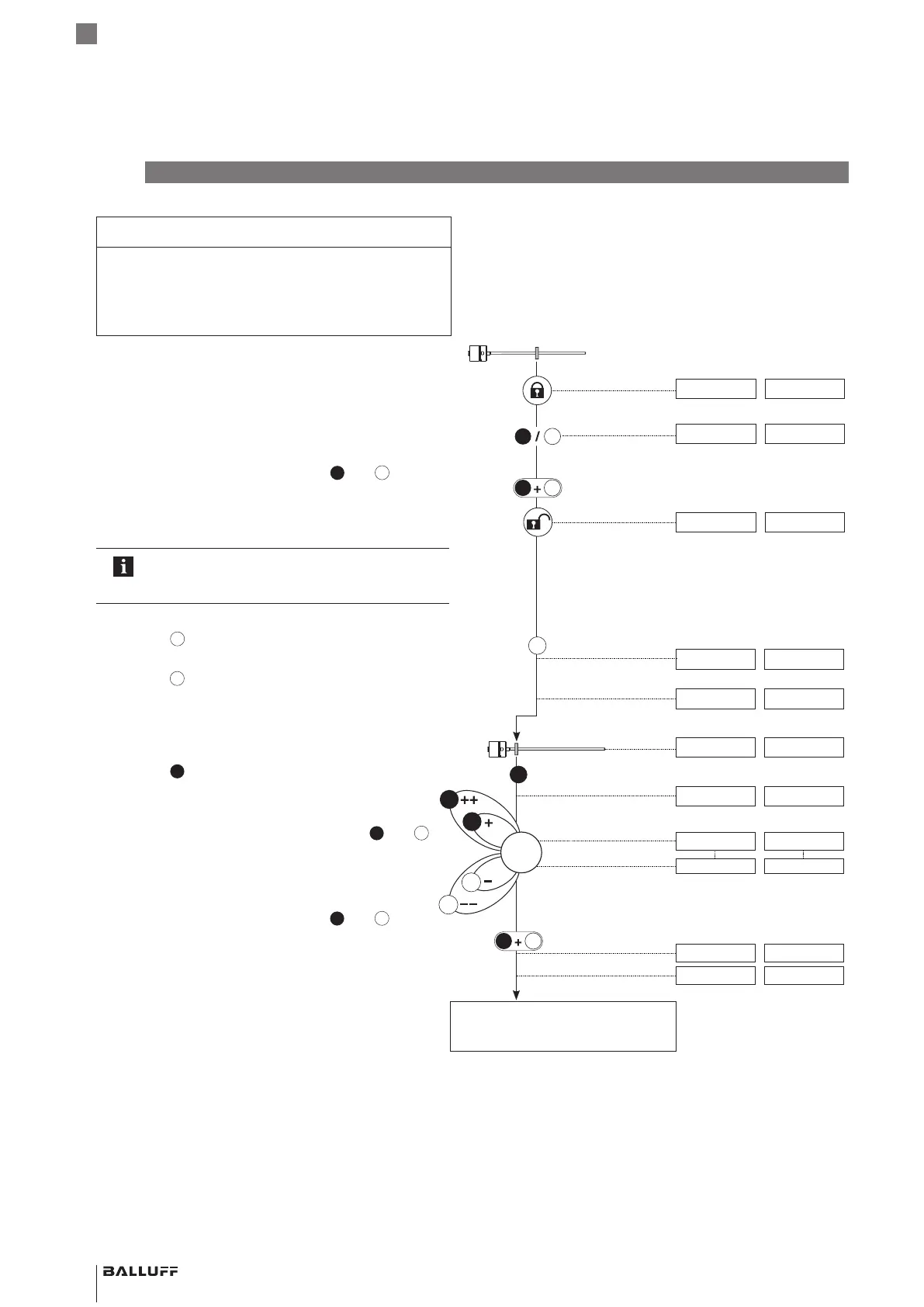

Adjusting

NOTICE

Interference in function

Adjustment while the system is running may result in

malfunctions.

► Stop the system before performing adjustment.

Displayed values (example)

At 0 to 10 V At 4 to 20 mA

Initial situation:

– BTL with magnet within measuring range

5.39 V 9.15 mA

1. Activate buttons

► Activate any button for at least 3s.

> 3 s

5.39 V 9.15 mA

► Release buttons.

< 1 s

► Simultaneously (within 1s) activate

and

for at

least 3s.

> 3 s

⇒ Output indicates error value.

10.50 V 3.60 mA

⇒ Buttons are activated.

If an error or an interruption occurs while

activating the buttons, allow a wait time of 12s

before retrying.

2. Select adjustment

► Activate

for at least 2s.

> 2s

⇒ Indication for “Adjustment” is displayed.

2.00 V 6.00mA

► Release

.

⇒ Current position value is displayed.

5.39 V 9.15 mA

3. Adjust start value

► Bring magnet to start position.

1.04 V 4.82 mA

► Activate

for at least 2s.

> 2s

⇒ Indication for “Adjust start value” is displayed.

0.00 V 4.00 mA

► Adjust start value.

⇒ The start value can be changed using

and

1)

.

The gradient of the output remains constant (see

page18).

1.04 V 4.82 mA

1.00 V 4.40 mA

► Exit calibration procedure: Activate

and

for no

more than 2 s.

< 2s

b

⇒ Indication for “Adjustment” is displayed.

2.00 V 6.00mA

⇒ Set position value is saved.

1.00 V 4.40 mA

Adjust end value

(see page23)

b

b

1) Briefly activate button: Current value is increased or

decreased by approx. 1mV or 1 µA.

If a button is activated longer than 1 s, the step interval is

increased.

BTL7-A/C/E/G5_ _-M_ _ _ _-J-DEXC-TA12

Magnetostrictive Linear Position Sensor – Rod Style

Type of protection “db” and “ta”

Flameproof enclosure

Loading...

Loading...