18 english

6.3.2 Adjusting

The detailed procedure for adjusting is

described on page22ff.

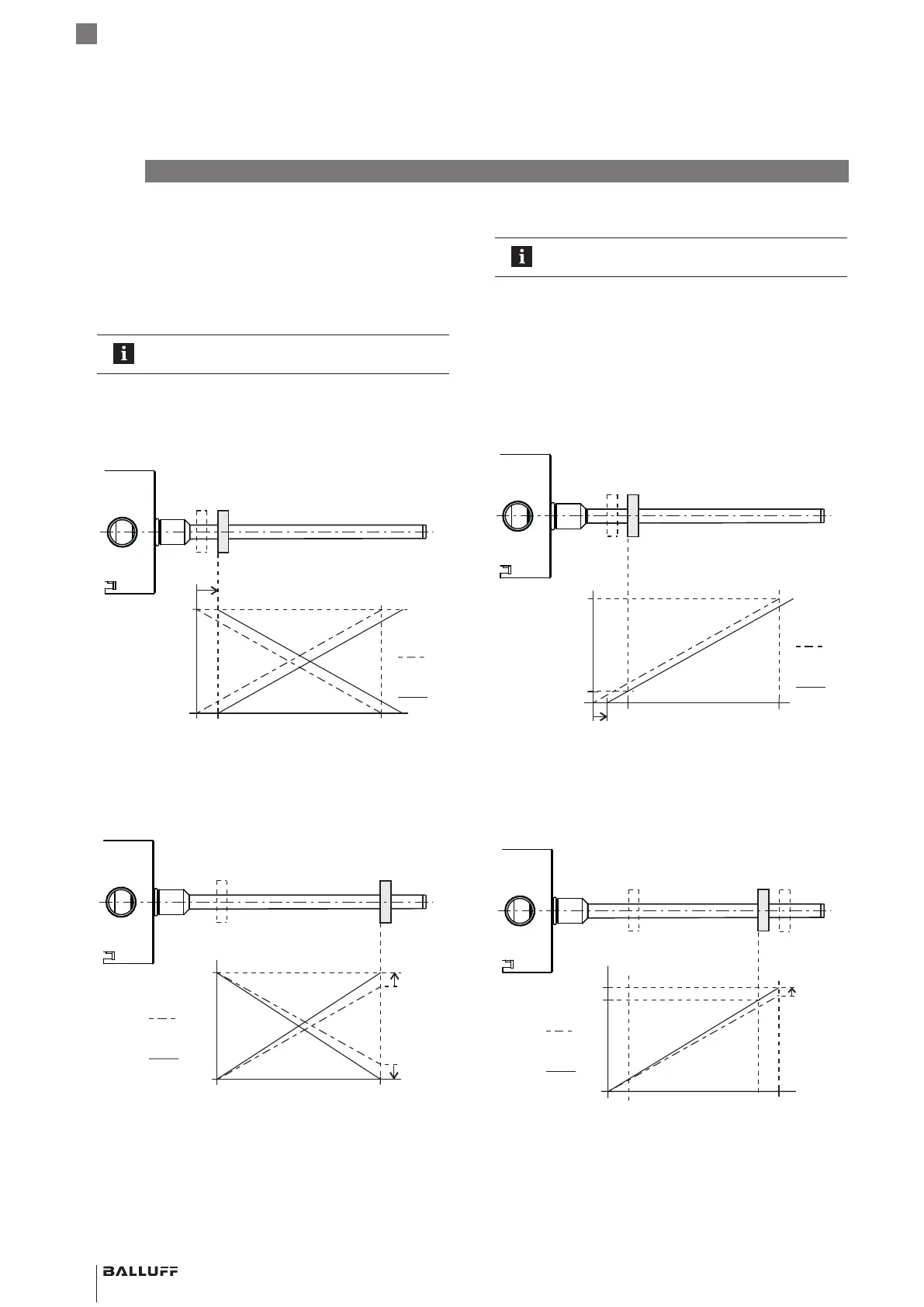

A new start and/or end value is adjusted. This is

recommended when the magnet cannot be brought to the

null point or end point.

Steps:

► Move magnet to the new start position.

► Set the desired start value by activating the buttons or

programming inputs.

Fig. 6-4:

New start value

Null point

Before

after

Adjusting new start position (offset shift)

► Move magnet to the new end position.

► Set the desired end value by activating the buttons or

programming inputs.

Fig. 6-5:

New end

value

Before

After

End point

Adjusting new end position (changing the output gradient)

6.3 Calibration procedure overview

6.3.1 Teach-in

The factory-set null point and end point are replaced by a

new null point and end point.

The detailed procedure for teach-in is described

on page21.

Steps:

► Move magnet to the new null position.

► Read new null point by activating the buttons or

programming inputs.

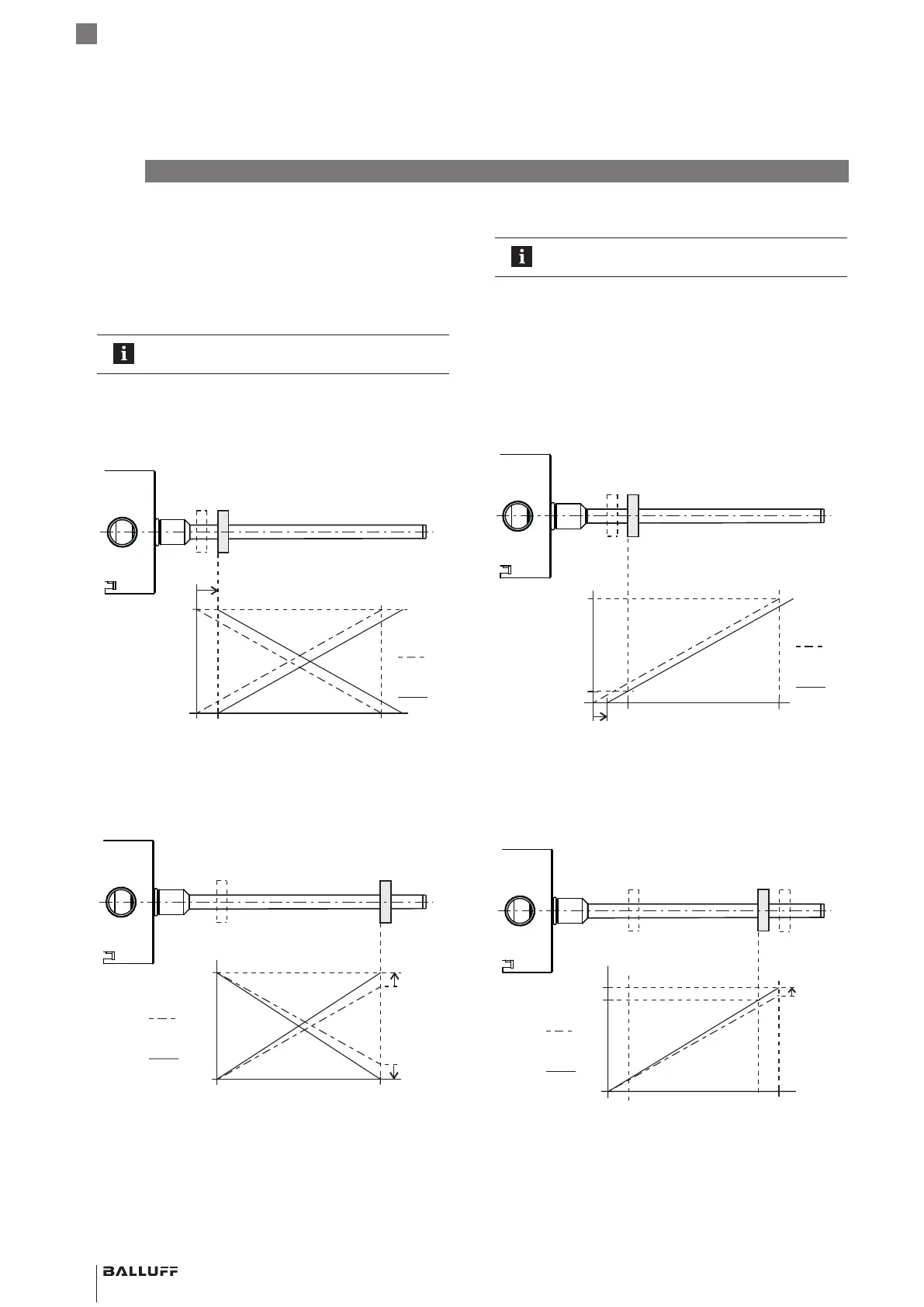

Fig. 6-2:

New null point

Before

After

Falling

Rising

Reading new null point (offset shift)

► Move magnet to the new end position.

► Read new end point by activating the buttons or

programming inputs.

Fig. 6-3:

New end point

Before

After

New measuring length 100%

Reading new end point (changing the output gradient)

6

Calibration procedure (continued)

BTL7-A/C/E/G5_ _-M_ _ _ _-J-DEXC-TA12

Magnetostrictive Linear Position Sensor – Rod Style

Type of protection “db” and “ta”

Flameproof enclosure

Loading...

Loading...