1

Intended use

The Transducer, together with a machine controller (e.g.

PLC), comprises a position measuring system. It is

intended to be installed into a machine or system and

used in the industrial sector. Flawless function in

accordance with the specifications in the technical data is

ensured only when using original Balluff accessories. Use

of any other components will void the warranty.

Opening the transducer or non-approved use are not

permitted and will result in the loss of warranty and liability

claims against the manufacturer.

General safety notes

Installation and startup may only be performed by

trained specialists.

The operator is responsible for ensuring that local safety

regulations are observed. In particular, the operator must

take steps to ensure that a defect in the position

measuring system will not result in hazards to persons or

equipment.

If defects and unresolvable faults occur in the transducer,

it should be taken out of service and secured against

unauthorized use.

Downloading further instructions

A complete user’s guide and the configuration guide can

be downloaded from the Internet at www.balluff.com or

requested via e-mail from service@balluff.de.

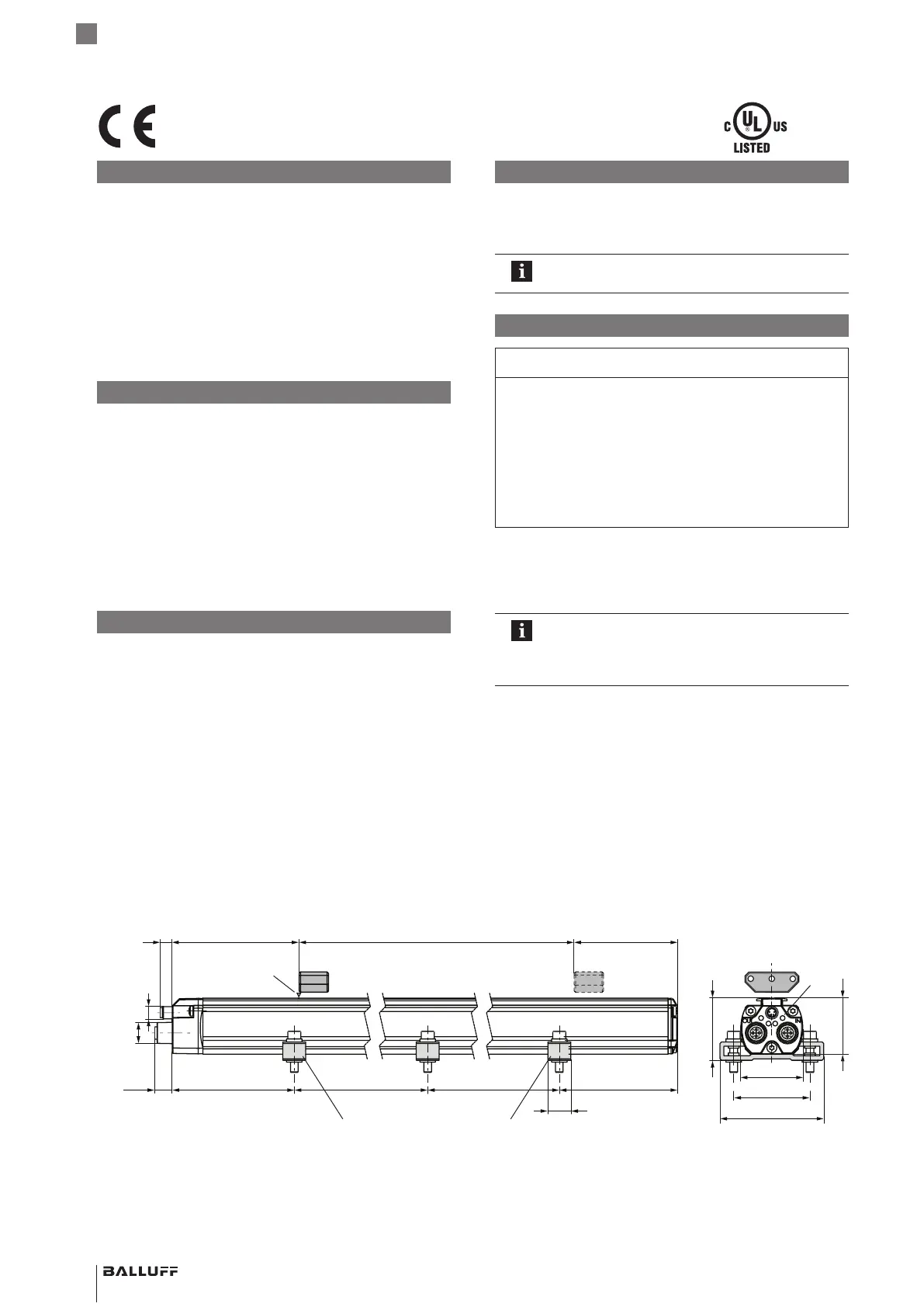

Dimensions and function

The transducer contains the waveguide. A magnet is

moved along the waveguide. This magnet defines the

position to be measured on the waveguide.

The descriptions of the LED displays can be

found in the comprehensive user’s guide.

Installation

NOTICE!

Improper installation

Improper installation can compromise the function of the

transducer and result in damage.

► For this reason, ensure that no strong electrical or

magnetic fields are present in the immediate vicinity

of the transducer.

► The recommended spacing for the installation must

be strictly observed.

Any orientation is permitted. Mount the transducer on a

level surface of the machine using the provided mounting

clamps and cylinder-head screws. A sufficient number of

mounting clamps is supplied.

In order to avoid the development of resonant

frequences from vibration loads, we recommend

arranging the mounting clamps at irregular

intervals.

The transducer is electrically isolated from the machine

with the supplied insulating bushes.

1. Guide the transducer into the mounting clamps.

2. Attach transducer to the base using mounting screws

(tighten screws in the clamps with max.2Nm).

3. Insert magnet (accessories).

english

The CE Mark verifies that our products

meet the requirements of the current

EMC Directive.

File no.

E227256

BTL7-V50D/E/T-M _ _ _ _ -P-C003

Transducer in a Profile Housing

50

40.6

68

41

36.8

~8011.5 ~80~250 ~250

15

88

3

11.5

M8

1) Unusable area

2) Not included in scope of delivery

3) Groove on the top side of the profile

marks the start of measuring range

1)

Nominal length =

Measuring range

BTL5-P-3800-2 magnet

1)

Mounting clamps with insulating bushes

and ISO4762M5x22 cylinder-head screws,

max. tightening torque 2Nm

2)

2)

Groove 3)

Null point End point

LEDs

Loading...

Loading...