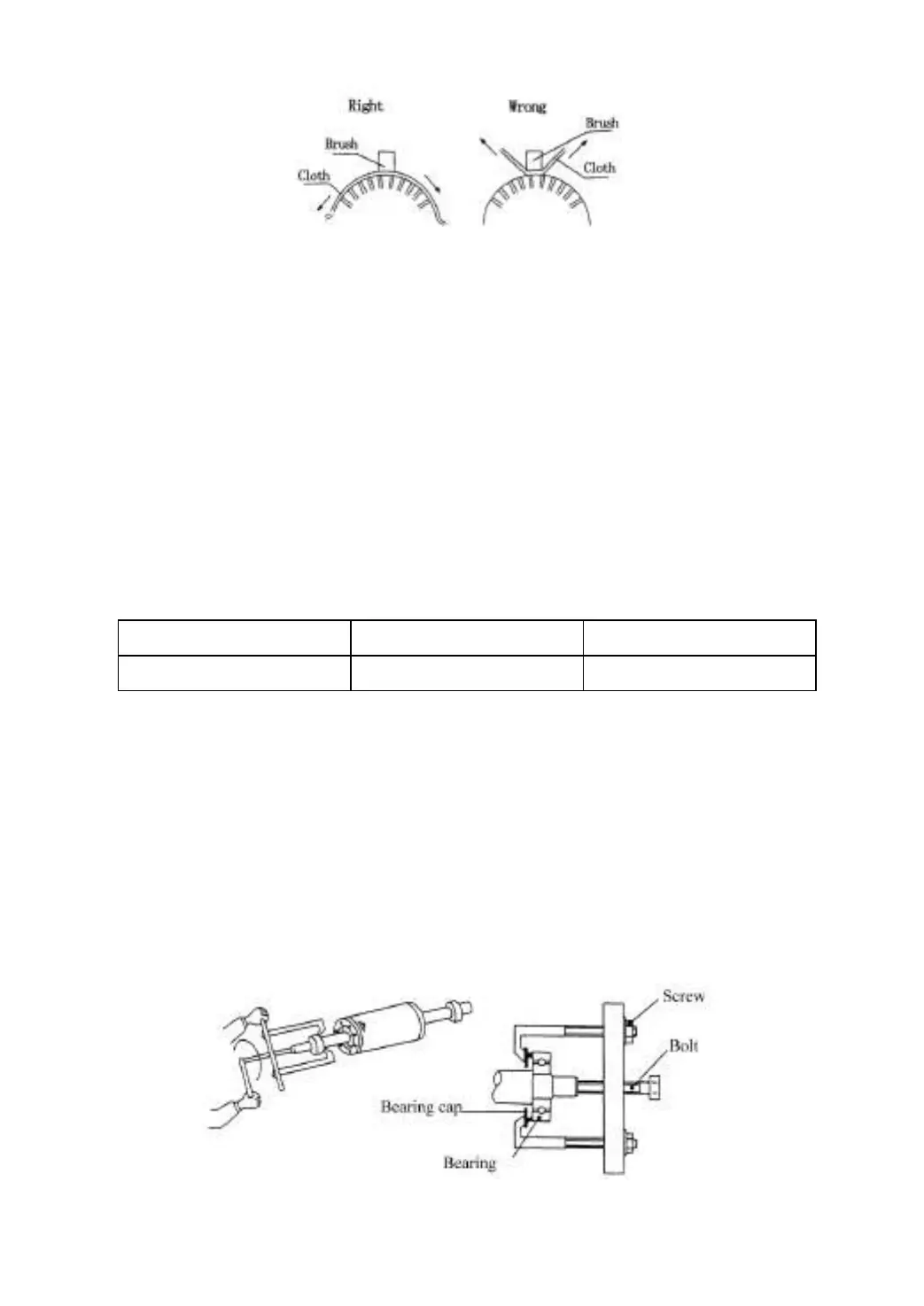

Fig. 5-4 Method of polishing

5. Inspection and maintenance of bearing

(1) Inspection and maintenance

The service life of the bearing varies with the load and driving condition. If the bearing

was observed high temperature or abnormal noise, replace it immediately.

Sealed bearing is of effective lubrication because it is sealed high quality lithium

grease, its structure also can prevent the dust from entering, with no need of replenishing

butter for long time.

Inspect the sealed bearing according to the following periods. If necessary, replace it.

Especially at thick dust place, or the place that butter may flow for deterioration because

of harmful gas or solvent, adding inspection frequency is necessary.

More than 12 hours

everyday

Less than 12 hours

everyday

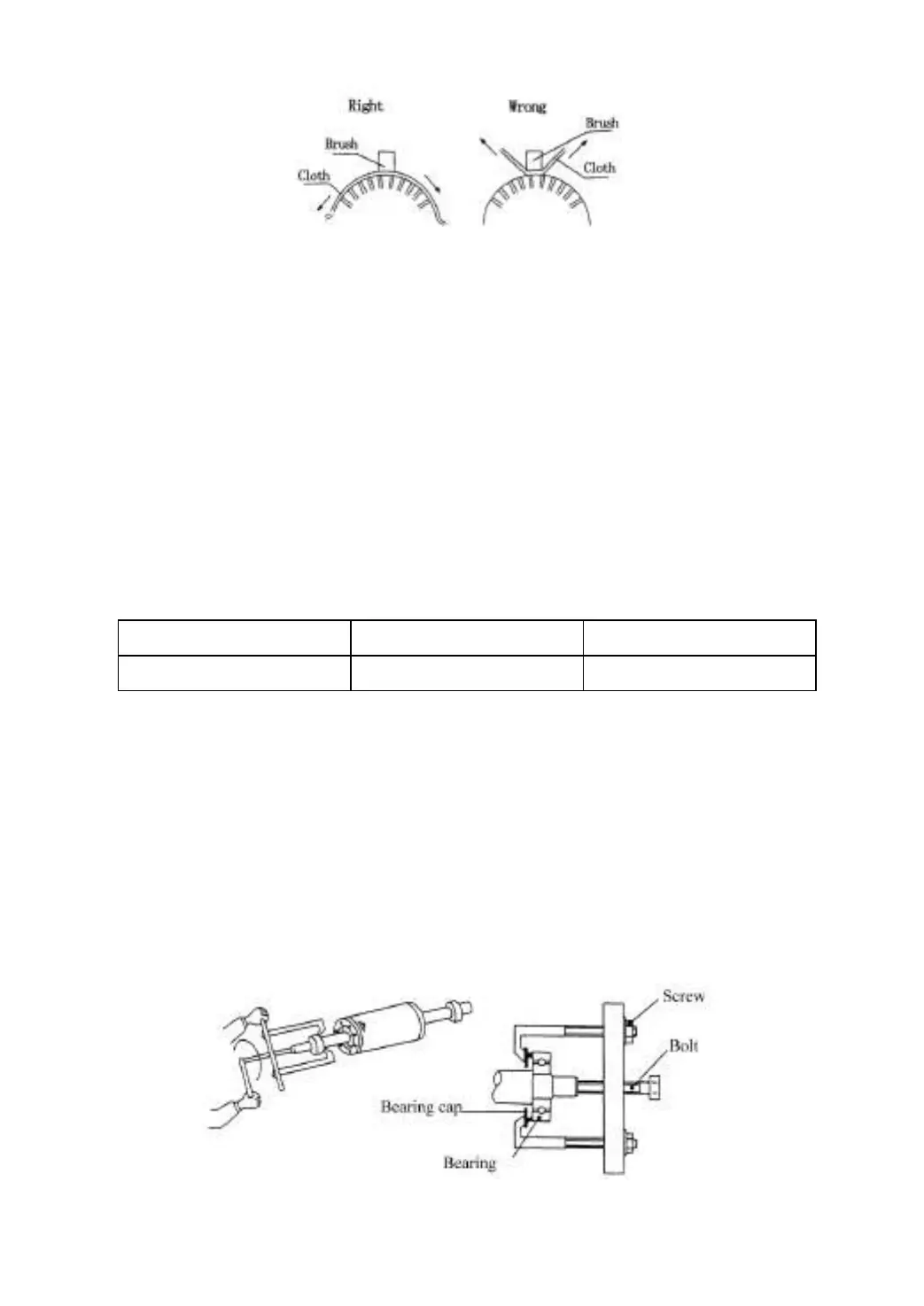

(2) Disassembly and assembly of bearing

If the bearing has abnormal noise or firing, disassemble the bearing from the shaft.

When disassembling, give a force on the outer circle of bearing with a small dismantler.

The bearing disassembled can not be used again (Fig.5-5).

When assembling a new bearing, give a force on the inner circle of the bearing with a

barrel appliance (Fig.5-6).

▲Disassemble bearing

Disassemble bearing with special dismantler.

Fig.5-5 Disassemble bearing

Loading...

Loading...