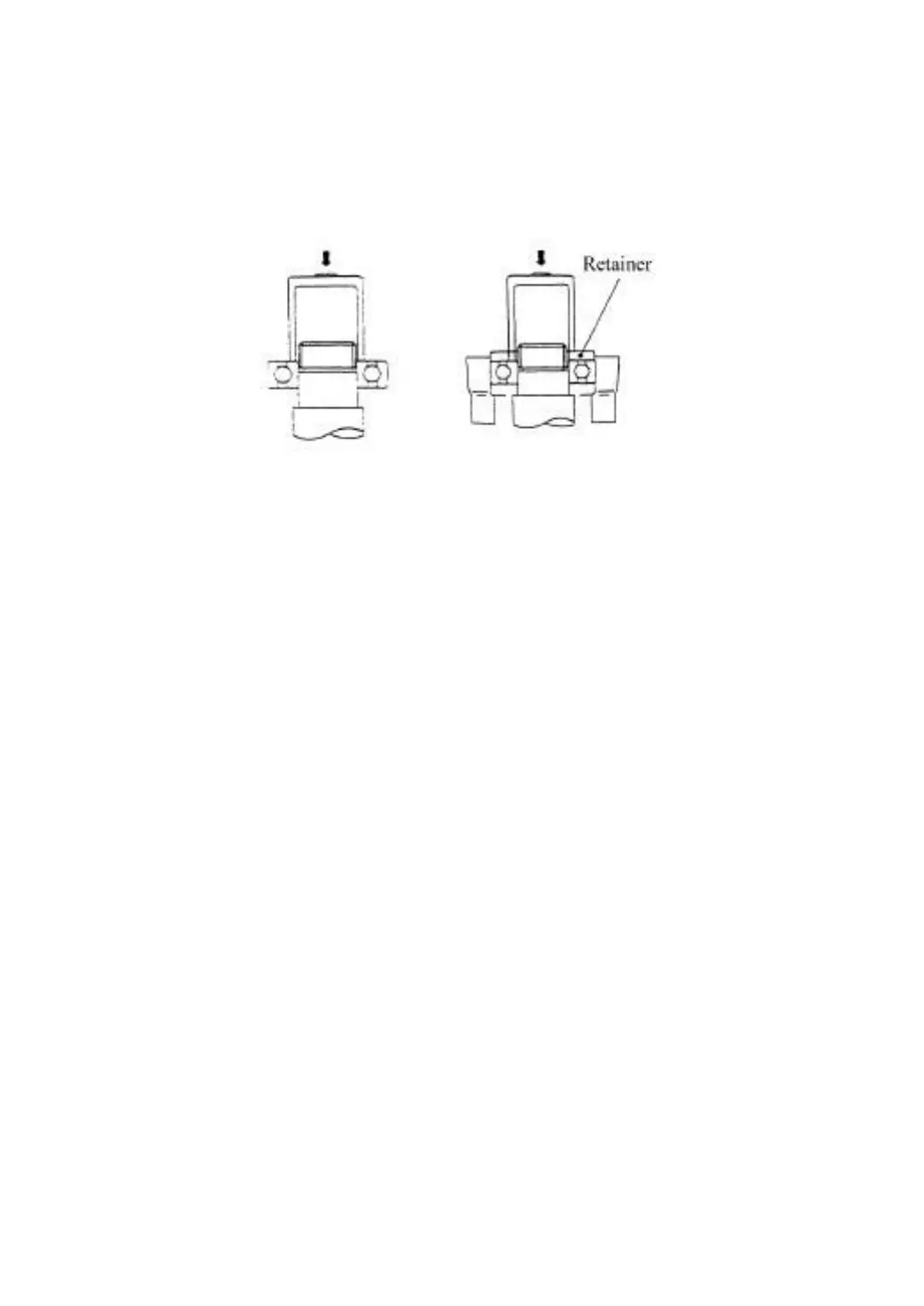

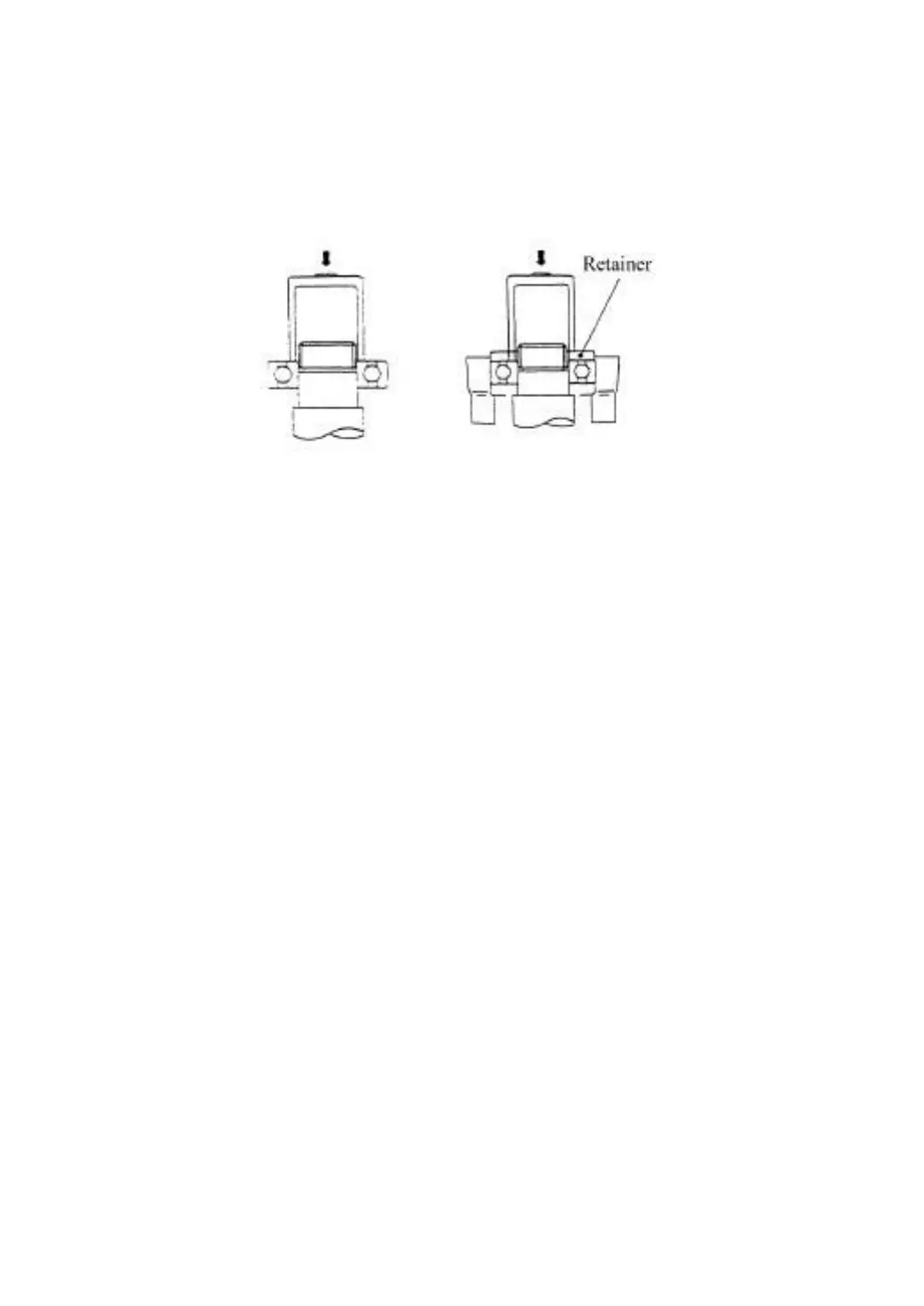

▲Assemble bearing

Assemble bearing with steel pipe or retainer.

The temperature can’t be out of 60℃-80℃ when loosening the motor bearing.

Fig.5-6 Assemble bearing

6. Measure insulating resistance

Connect negative pole of the meter with motor bedplate, positive pole with either of

the two terminals, the measured value should be more than 0.5 MΩ.

If the measured value below 0.5 MΩ, clean the baked carbon in the motor with

compressed air, if necessary, dry the motor with airer, then measure it again. If the

measured value is still abnormal, replace the motor.

7. Inspection of rectifier

Rectifier is the most important part of the motor. If oil or foreign matter adhered on it,

it will cause electric brush excessive roughness and weaken the efficiency of the rectifier.

Clean it with compressed air or dry cloth.

Polish up the roughness of the rectifier surface with 500# or 600# sand paper and

clean carefully. If appearing excessive roughness, maintain the rectifier with cutting tools.

After the cutting, correct the thickness of mica lamination.

Maintaining rectifier needs special mechanical tool, so you’d better call qualified

serviceman.

Loading...

Loading...