Crankshaft

The crankshaft has been machined with the highest

possible accuracy.

To obtain this optimal accuracy and inherent minimal

clearances, very special machines and measuring tools

are needed.

In a very sporadic case of a needed replacement of the

connecting rod, we therefore strongly recommend

replacement of a complete crankshaft.

Otherwise the accuracy can not be assured.

The little end bush in the connecting rod is made out of

bronze.

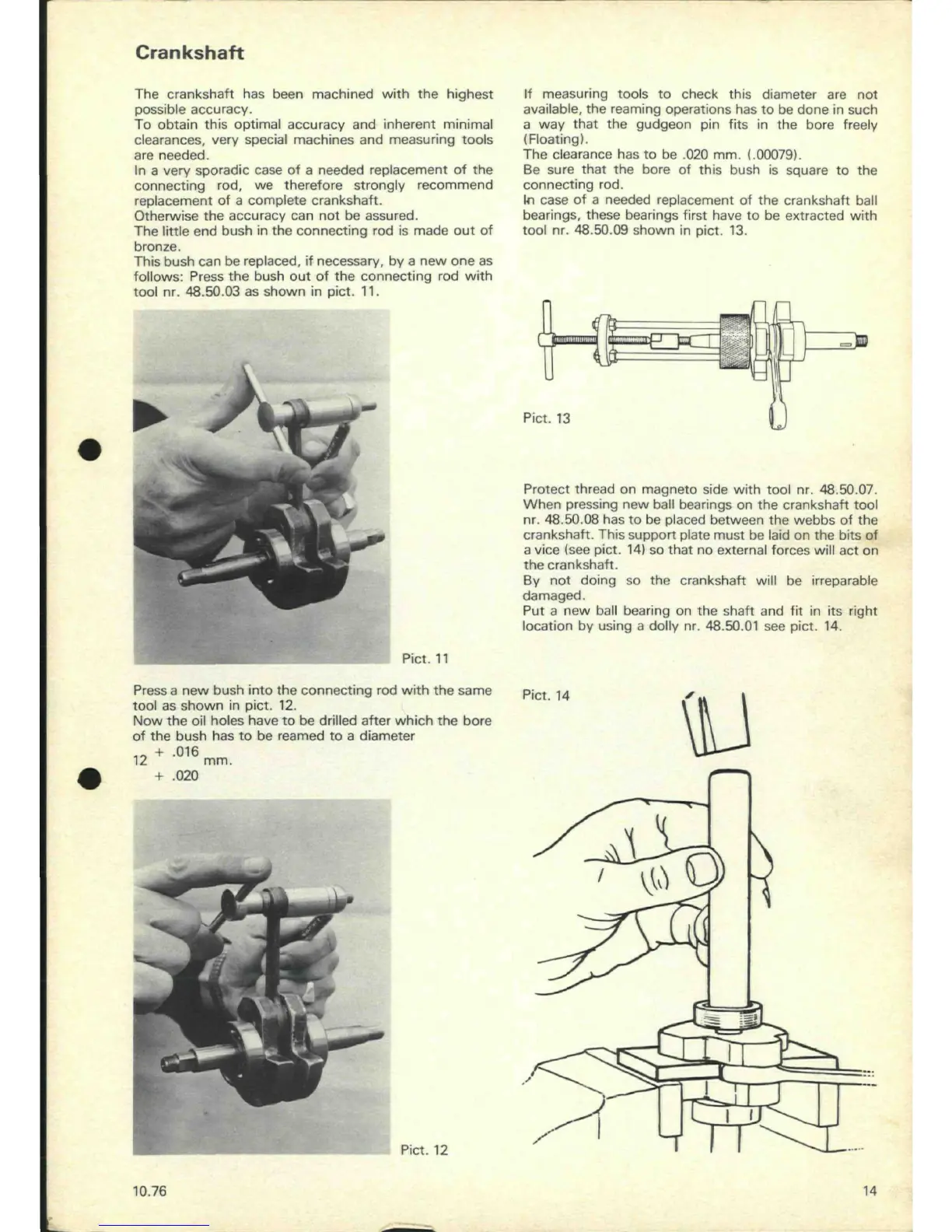

This bush can be replaced, if necessary, by a new one as

follows: Press the bush out of the connecting rod with

tool nr. 48.50.03 as shown in pict. 11.

•

Pict.

11

Press a new bush into the connecting rod with the same

tool as shown in pict. 12.

Now the oil holes have to be drilled after which the bore

of the bush has to be reamed to a diameter

,.

+ .016

12 mm.

+ .020

-*

Pict. 12

If measuring tools to check this diameter are not

available, the reaming operations has to be done in such

a way that the gudgeon pin fits in the bore freely

(Floating).

The clearance has to be .020 mm. (.00079).

Be sure that the bore of this bush is square to the

connecting rod.

In

case of a needed replacement of the crankshaft ball

bearings, these bearings first have to be extracted with

tool nr. 48.50.09 shown in pict. 13.

'J

)3

•,-•'-

i ,.-•-.,r

<

Pict. 13

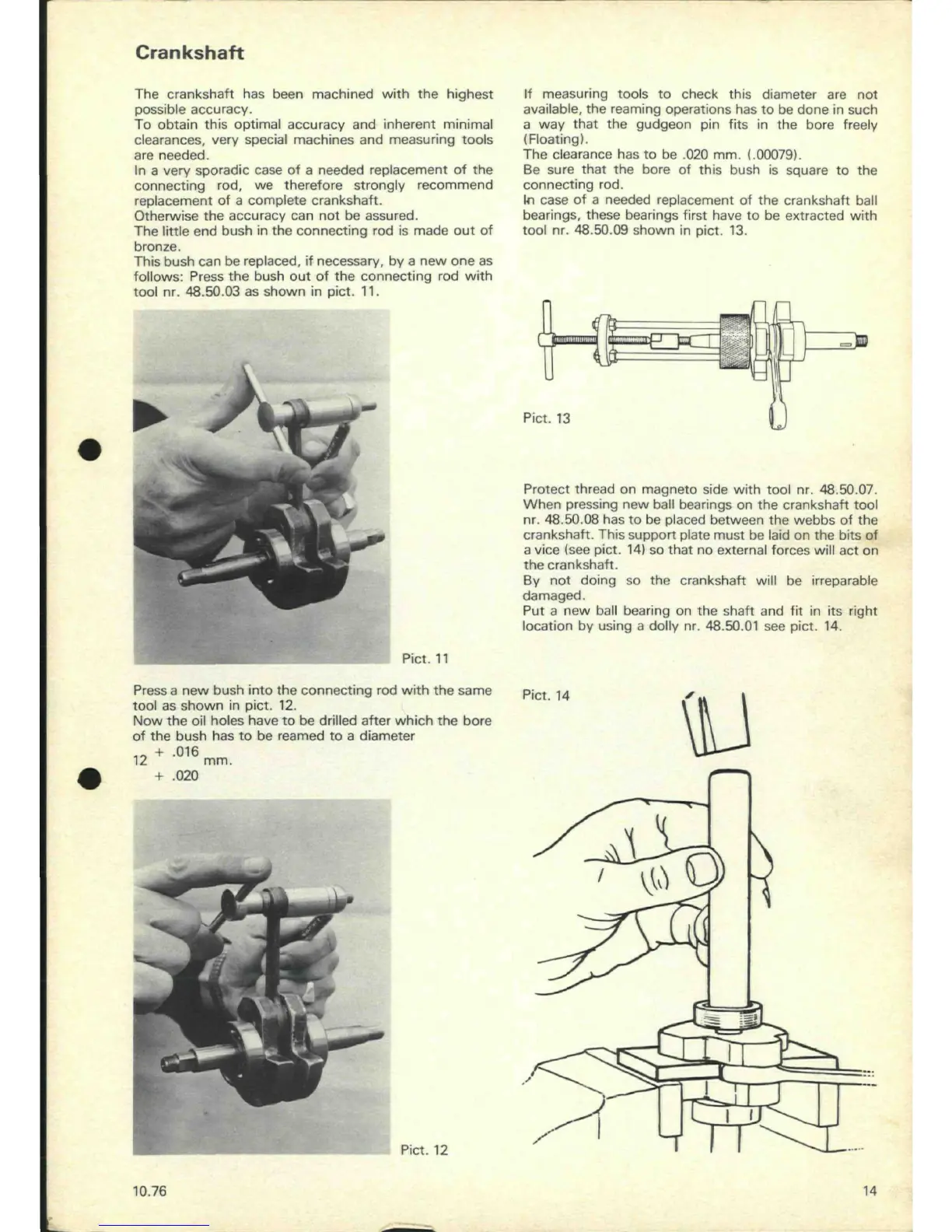

Protect thread on magneto side with tool nr. 48.50.07.

When pressing new ball bearings on the crankshaft tool

nr. 48.50.08 has to be placed between the webbs of the

crankshaft. This support plate must be laid on the bits of

a vice (see pict. 14) so that no external forces will act on

the crankshaft.

By not doing so the crankshaft will be irreparable

damaged.

Put a new ball bearing on the shaft and fit in its right

location by using a dolly nr. 48.50.01 see pict. 14.

Pict. 14

\u

\

\

I

\

5

^

!

s

T

10.76

14

Loading...

Loading...