Ignition 6 V - 29/5 W.

Valid for: 20

mph.

engines to nr. 772302

25 mph. engines to nr.

779301

30 mph. engines to nr. 780501

The ignition is supplied

with:

1 Coil 29 W. for the headlight

1 Coil 5 W. for additional charging of the

battery

1 H.T. coil

All these coils are mounted on the base plate, placed in

the flywheel.

When dismounting the flywheel it must be secured by

tool

nr. 48.50.10.

After removing the nut, the flywheel can be pulled off

with tool nr. 48.50.02 secured again with tool nr.

48.50.10.

Always put the flywheel with the open side upwards on

the workbench to prevent iron parts, like small washers,

to be attracted by the magnetos.

Loosen the 3 screws of the base plate and remove the

baseplate out of its position in the crankcase.

In order to move the wires freely through the rubber

grommets, oil them a little before.

Never pull the base plate to move the wires out of the

grommets but always pull the wires themselves.

Mounting the ignition the wires have to be put into the

grommets first. Some oil on the wires makes it easier.

Fit the base plate into the crankcase location, between

the cams. Take care that this is done correctly and that

no wire is pinched between base plate and casting.

Fit the 3 screws but doe not yet tighten them.

Next mount the flywheel and make sure that the key fits

in the key groove of the flywheel. Fit plain washer,

toothed washer and nut on the crankshaft.

Secure the flywheel again with tool nr. 48.50.10 and

tighten the nut.

Now turn the flywheel clockwise until the breaker gap is

maximum, visible through the holes in the flywheel.

Check the breaker gap.

The gap must be between .35 and .45 mm. (.014 and

.018").

If the gap is not correct it can be adjusted by loosening

the screw of the breakerpoint set, and moving the fixed

contact into the desired direction by means of a screw

driver.

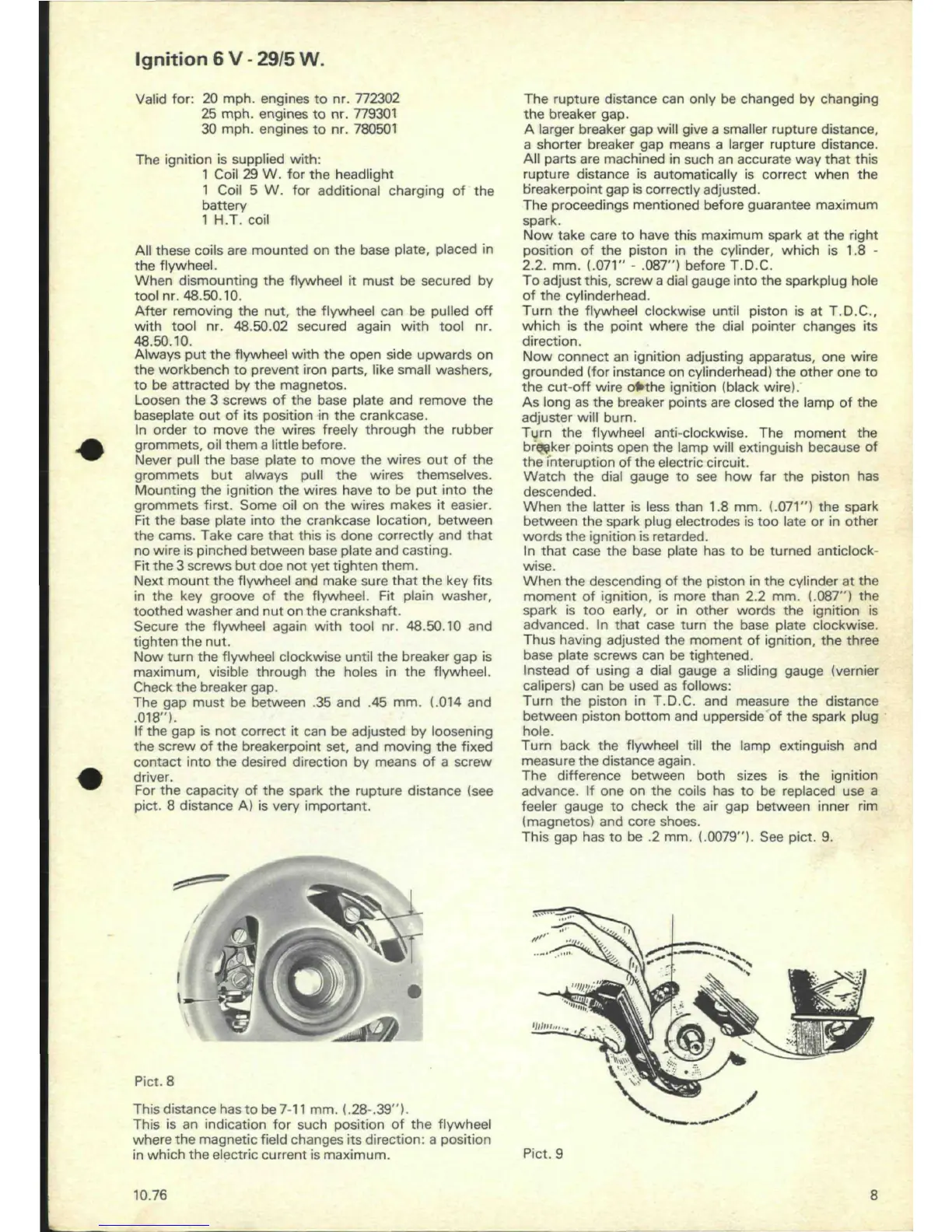

For the capacity of the spark the rupture distance (see

pict. 8 distance A) is very important.

/

:

\

Pict. 8

This distance

has

to

be

7-11

mm.

(.28.39").

This is an indication for such position of the flywheel

where the magnetic field changes its direction: a position

in which the electric current is maximum.

The rupture distance can only be changed by changing

the breaker gap.

A larger breaker gap will give a smaller rupture distance,

a shorter breaker gap means a larger rupture distance.

All parts are machined in such an accurate way that this

rupture distance is automatically is correct when the

breakerpoint gap is correctly adjusted.

The proceedings mentioned before guarantee maximum

spark.

Now take care to have this maximum spark at the right

position of the piston in the cylinder, which is 1.8 -

2.2.

mm.

(.071"

- .087") before

T.D.C.

To adjust this, screw a dial gauge into the sparkplug hole

of the cylinderhead.

Turn the flywheel clockwise until piston is at T.D.C,

which is the point where the dial pointer changes its

direction.

Now connect an ignition adjusting apparatus, one wire

grounded (for instance on cylinderhead) the other one to

the cut-off wire

ofrthe

ignition (black wire).

As long as the breaker points are closed the lamp of the

adjuster will burn.

Turn the flywheel anti-clockwise. The moment the

breaker

points open the lamp will extinguish because of

the interuption of the electric circuit.

Watch the dial gauge to see how far the piston has

descended.

When the latter is less than 1.8 mm.

(.071")

the spark

between the spark plug electrodes is too late or in other

words the ignition is retarded.

In that case the base plate has to be turned anticlock-

wise.

When the descending of the piston in the cylinder at the

moment of ignition, is more than 2.2 mm.

(.087")

the

spark is too early, or in other words the ignition is

advanced.

In that case turn the base plate clockwise.

Thus having adjusted the moment of ignition, the three

base plate screws can be tightened.

Instead of using a dial gauge a sliding gauge (vernier

calipers) can be used as follows:

Turn the piston in T.D.C. and measure the distance

between piston bottom and upperside of the spark plug

hole.

Turn back the flywheel till the lamp extinguish and

measure the distance again.

The difference between both sizes is the ignition

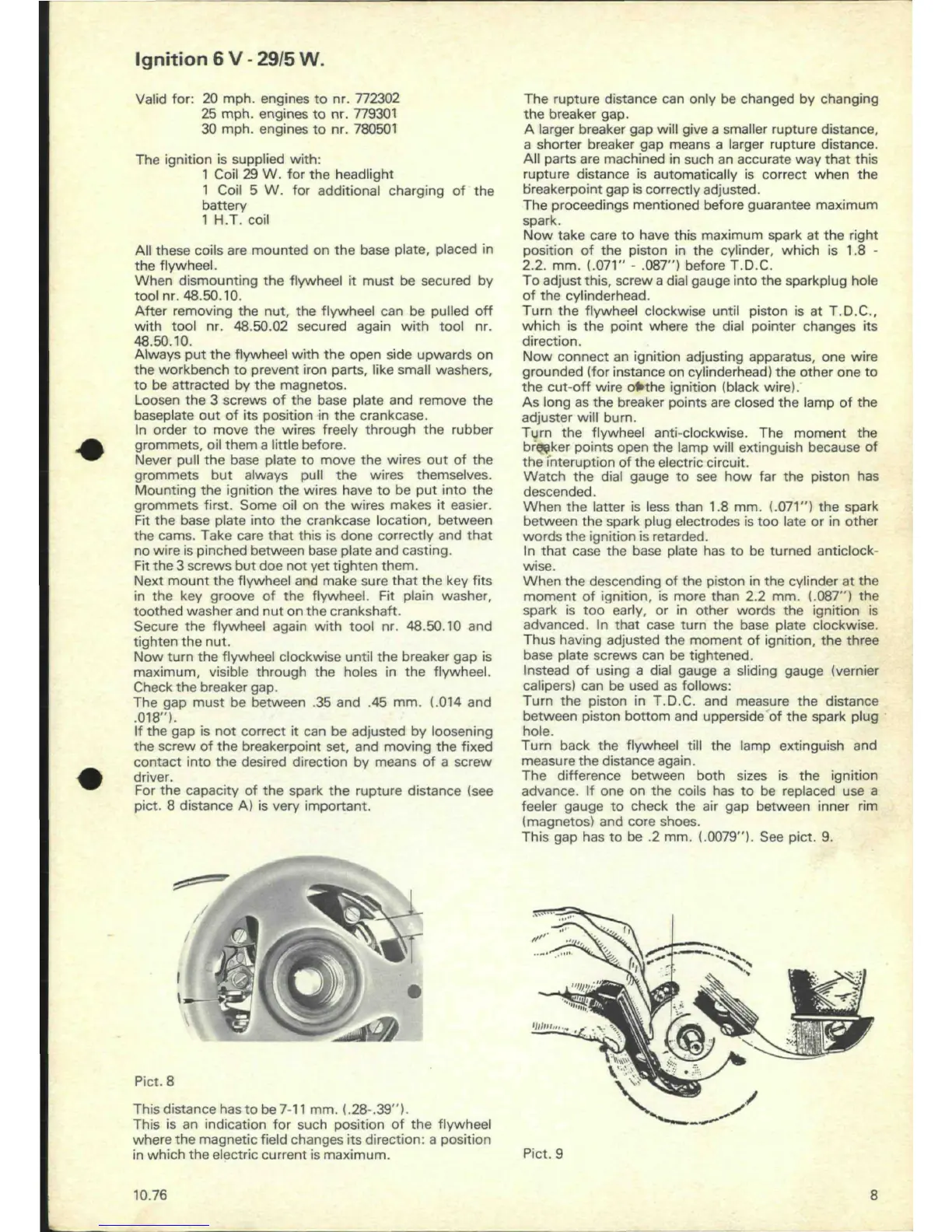

advance. If one on the coils has to be replaced use a

feeler gauge to check the air gap between inner rim

(magnetos) and core shoes.

This gap has to be .2 mm. (.0079"). See pict. 9.

'

!

>

V>

•m

i

limn

i

-v

s

s

Pict. 9

10.76 8

Loading...

Loading...