Cylinder and cylinderhead

The

M

48 engine is equiped with a cast iron cylinder.

A cast iron cylinder is cheaper than an aluminum one and

has also the advantage that the cylinderbore can be

rehoned after being damaged.

As the specific power of these engines is relatively low

(abt. .7 hp/cu.in.) the heat abstraction is sufficient.

Hence an aluminum cylinder is not necessary.

In the case of a rehoned cylinderbore an oversize piston

should be applied.

In order to get the required piston clearance the diameter

of the bore has to be rehoned to 40.245 - 40.255 mm.

Before dismantling the cylinder, the surroundings of the

cylinderbase have to be cleaned with a brush and

kerosine to prevent dirt from getting into the crankcase.

Remove the sparkplug.

Remove the 4 nuts of the cylinderstuds (take care that

the plain washers and the spring washers do not get

lost) and the two bolts of the exhaust pipe.

Remove the cylinderhead and carefully take off the

cylinder.

Remove the cylinder base gasket.

Put a not fluffy rag around the connecting rod to prevent

dirt from getting into the housing.

Take care that the joint surfaces will not be damaged.

Before assembling cylinder and cylinderhead the joint

surfaces have to be cleaned very carefully (dont scratch!)

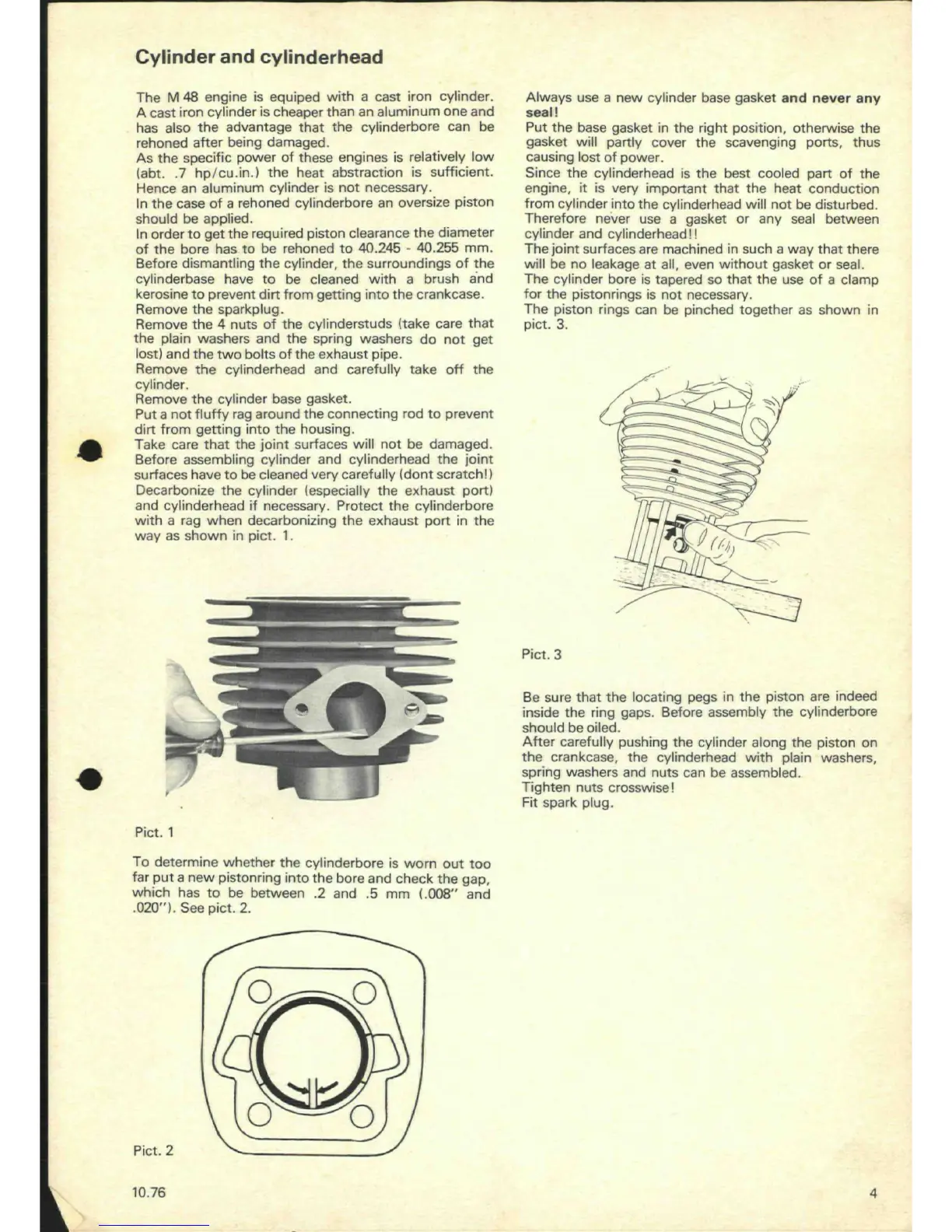

Decarbonize the cylinder (especially the exhaust port)

and cylinderhead if necessary. Protect the cylinderbore

with a rag when decarbonizing the exhaust port in the

way as shown in pict.

1.

Always use a new cylinder base gasket and never any

seal!

Put the base gasket in the right position, otherwise the

gasket will partly cover the scavenging ports, thus

causing lost of power.

Since the cylinderhead is the best cooled part of the

engine, it is very important that the heat conduction

from cylinder into the cylinderhead will not be disturbed.

Therefore never use a gasket or any seal between

cylinder and cylinderhead!!

The joint surfaces are machined in such a way that there

will be no leakage at all, even without gasket or

seal.

The cylinder bore is tapered so that the use of a clamp

for the pistonrings is not necessary.

The piston rings can be pinched together as shown in

pict. 3.

Pict. 3

Be sure that the locating pegs in the piston are indeed

inside the ring gaps. Before assembly the cylinderbore

should be oiled.

After carefully pushing the cylinder along the piston on

the crankcase, the cylinderhead with plain washers,

spring washers and nuts can be assembled.

Tighten nuts crosswise!

Fit spark

plug.

Pict. 1

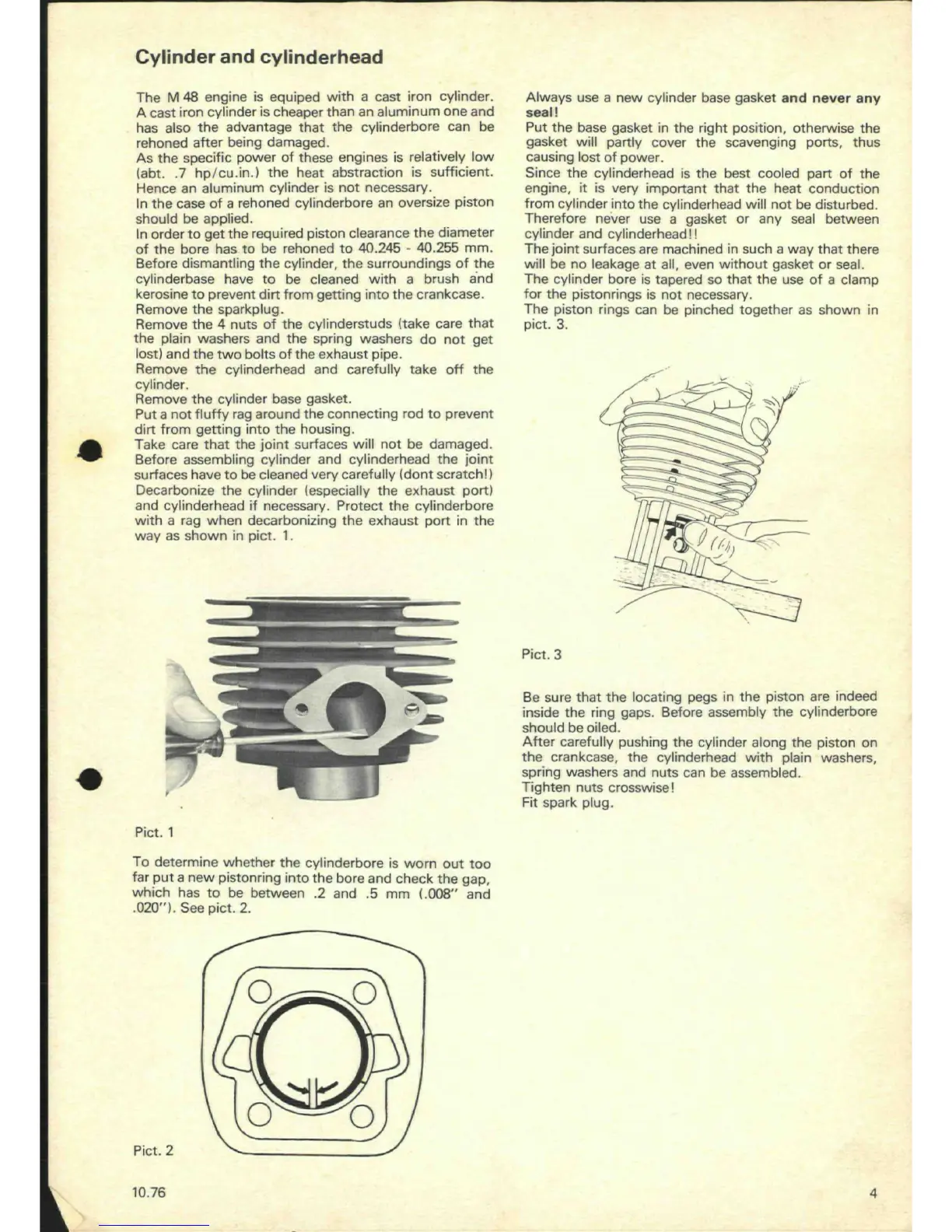

To determine whether the cylinderbore is worn out too

far put a new pistonring into the bore and check the gap,

which has to be between .2 and .5 mm (.008" and

.020").

See pict. 2.

Pict. 2

10.76

4

Loading...

Loading...