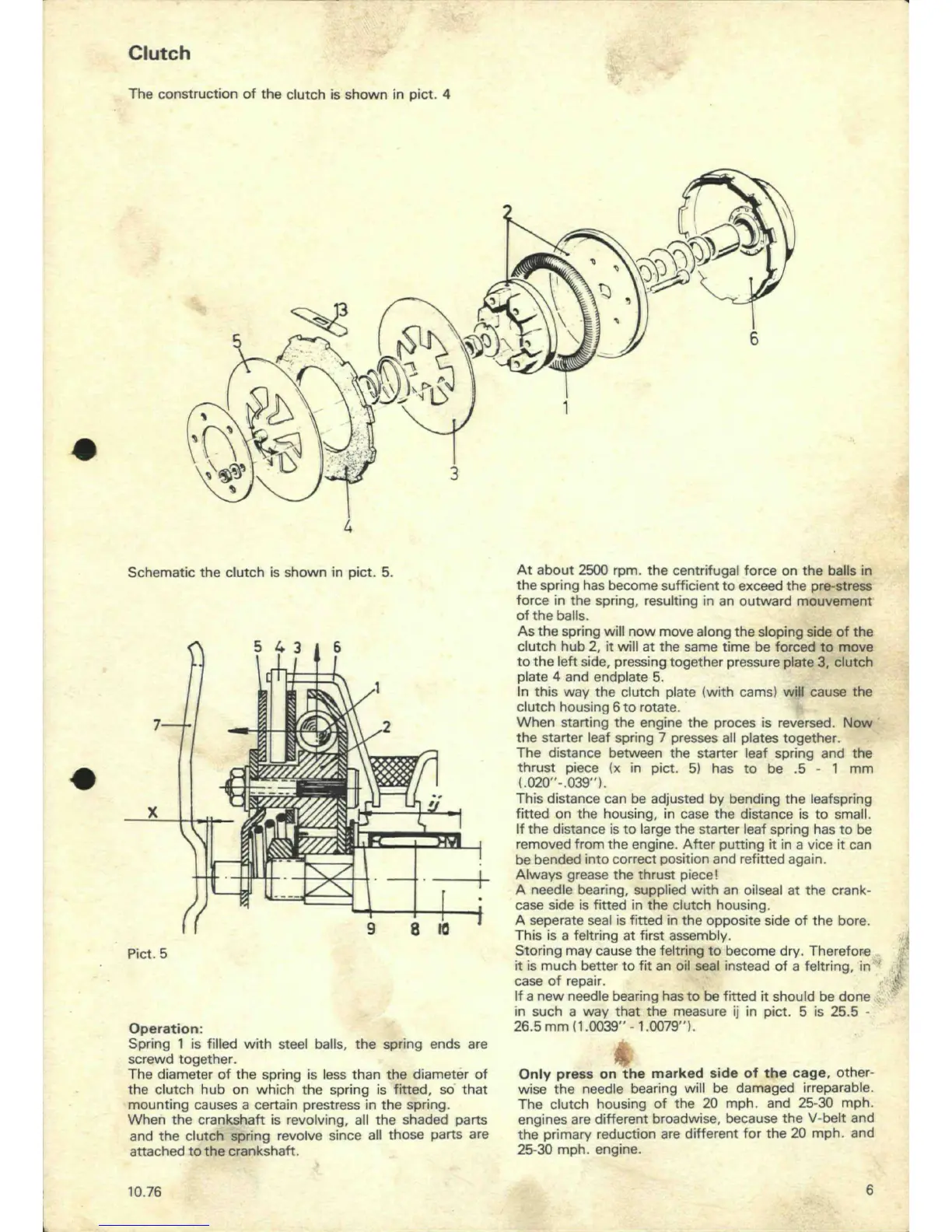

Clutch

The construction of the clutch is shown in pict. 4

$&

v\

m

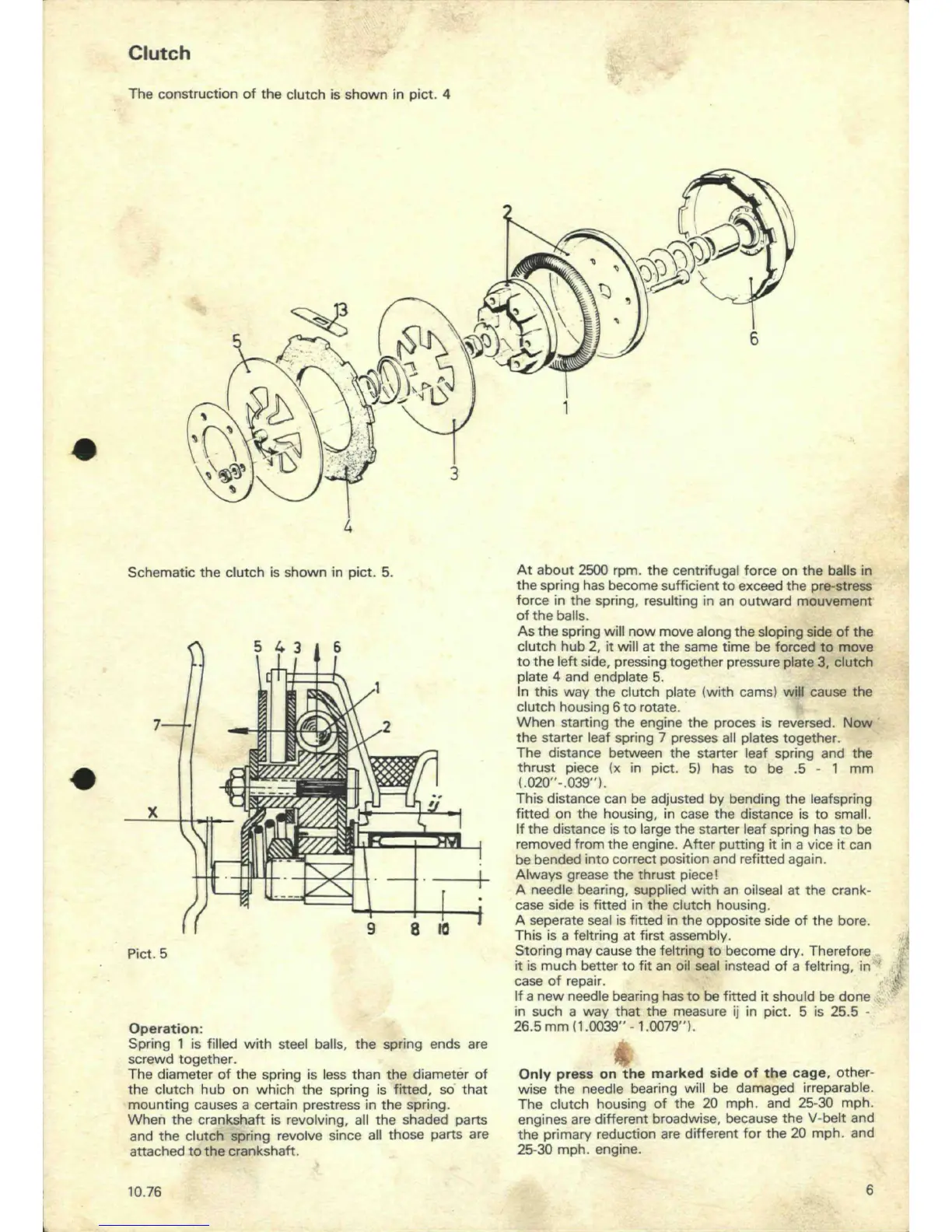

Schematic the clutch is shown in pict. 5.

H

•

M

(

9 8

10

Pict. 5

Operation:

Spring 1 is filled with steel balls, the spring ends are

screwd together.

The diameter of the spring is less than the diameter of

the clutch hub on which the spring is fitted, so that

mounting causes a certain prestress in the spring.

When the crankshaft is revolving, all the shaded parts

and the clutch spring revolve since all those parts are

attached to the crankshaft.

At about 2500

rpm.

the centrifugal force on the balls in

the spring has become sufficient to exceed the

pre-stress

force in the spring, resulting in an outward mouvement

of the balls.

As the spring will now move along the sloping side of the

clutch hub 2, it will at the same time be forced to move

to the left side, pressing together pressure plate 3, clutch

plate 4 and endplate 5.

In this way the clutch plate (with cams) will cause the

clutch housing 6 to rotate.

When starting the engine the proces is reversed. Now

the starter leaf spring 7 presses all plates together.

The distance between the starter leaf spring and the

thrust piece (x in pict. 5) has to be .5 - 1 mm

<.020"-.039").

This distance can be adjusted by bending the leafspring

fitted on the housing, in case the distance is to small.

If the distance is to large the starter leaf spring has to be

removed from the engine. After putting it in a vice it can

be bended into correct position and refitted again.

Always grease the thrust piece!

A needle bearing, supplied with an oilseal at the crank-

case side is fitted in the clutch housing.

A seperate seal is fitted in the opposite side of the bore.

This is a feltring at first assembly.

Storing may cause the feltring to become dry. Therefore

it is much better to fit an oil seal instead of a feltring, in

case of repair.

If a new needle bearing has to be fitted it should be done

in such a way that the measure ij in pict. 5 is 25.5 -

26.5 mm (1.0039"

-1.0079").

4

Only press on the marked side of the cage, other-

wise the needle bearing will be damaged irreparable.

The clutch housing of the 20

mph.

and 25-30

mph.

engines are different broadwise, because the

V-belt

and

the primary reduction are different for the 20 mph. and

25-30 mph. engine.

10.76

6

Loading...

Loading...