TAM 00695 18

DST2-135 – 400 W 10 / 2019

Three-phase synchronous motor, water-cooled English

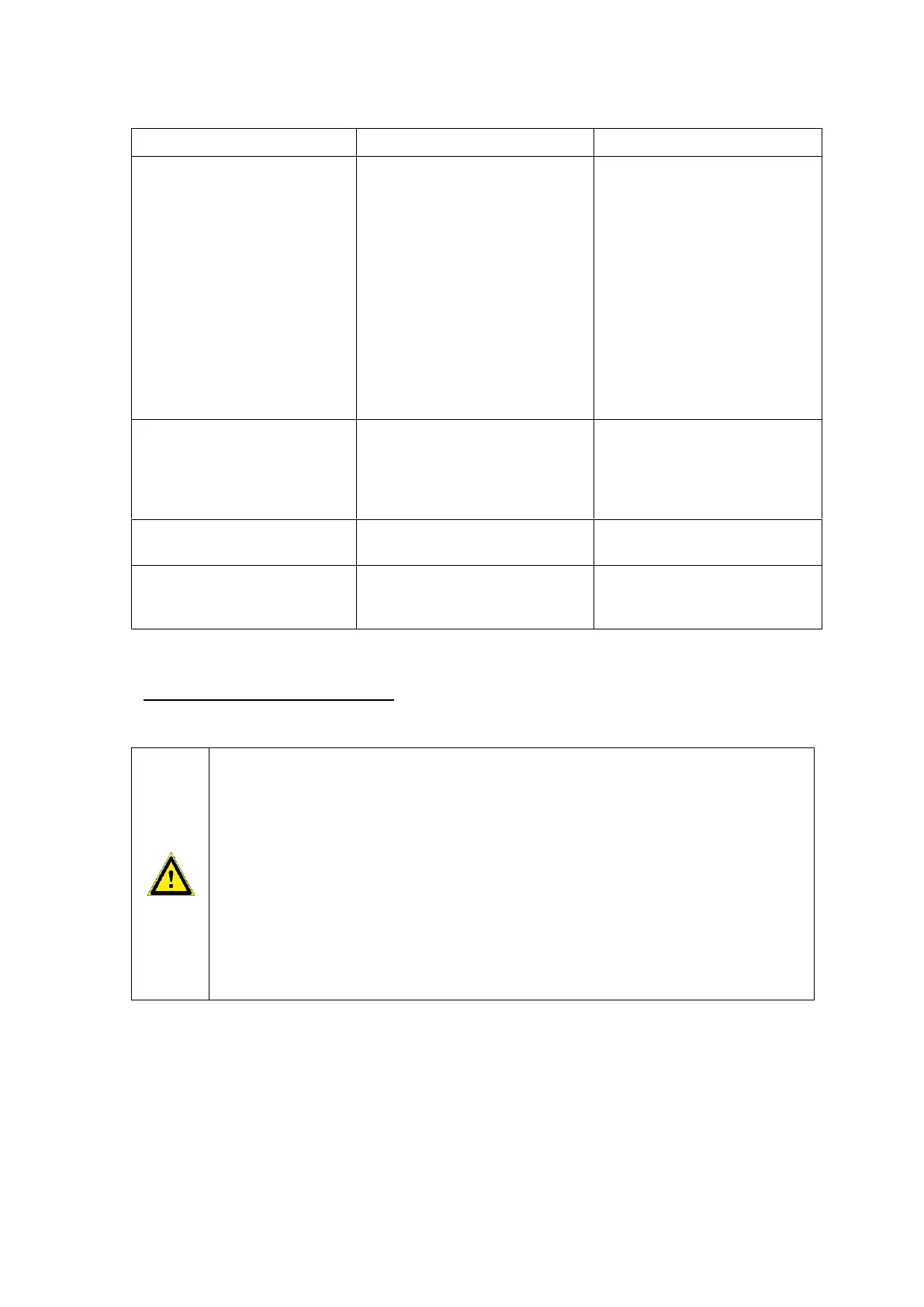

Temperature rise in motor

Motor temperature monitoring

unit responds

Drive overloaded

Brake does not release fully -

scraping brake

Water cooling not active.

Coolant supply inadequate

- filter urgently requires

cleaning

- deposits in cooling channels

- disturbances in external

cooling system

Check motor load and

compare with nameplate

Repair by motor manufacturer

Check and, if necessary,

switch on

Check water circuit

- check and, if ecessary,clean

- check and, if ecessary,clean

- follow system suppier's

instructions

Excess pressure in cooling

system

Coolant impure

Cooling channels blocked

Disturbances in the external

cooling system

Filter coolant

Check and, if necessary, clean

Follow system suppier's

instructions

Current consumption too high,

motor torque too low

Check indexing angle and

adjust if necessary

Oil leak on A-side shaft

extension or leak hole

(Appendix 3)

Shaft sealing ring damaged or

worn

Repairs carried out by motor

manufacturer

Table 4: Malfunctions

5 Inspection and maintenance

Working on the electric motor:

Work must not be carried out on the electric motor until the motor has come to a

standstill, is de-energized, depressurised and has cooled. All connections, such as

screw connections, that were loosened must be tightened again after the inspection

or maintenance work.

When carrying out work on the motor, please observe the technical instructions and

notes in the respective Sections in these Commissioning and Manitenance

Instructions.

When carrying out maintenance work, observe all safety instructions which also apply

for the commissioning of the motor (comp. Section 4.1).

Attention!:

If the optional holding brake is fitted, this brake must not perform a safety function

during work on the motor (e. g. retaining loads)!

5.1 Inspection

Depending on the pollution severity on site, cleaning will have to be carried out regularly to

guarantee the continuous dissipation of heat loss. The flow rate and the pressure ratio of the

cooling system must be checked.

If an optional brake is fitted, wear limits are specified (e. g., maximum permissible operating air

gap, maximum number of emergency braking operations). The actual degree of wear on the brake

must be checked at regular intervals. When the permissible wear limits have been reached, the

brake must be replaced (see Section 5.2).

Loading...

Loading...